Water- emulsion type cylinder laser plate-making material with water resistance

A water-emulsion type, water-resistant technology, applied in the preparation of the printing surface, plate preparation, printing, etc., to achieve the effects of short curing temperature, improved water resistance, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

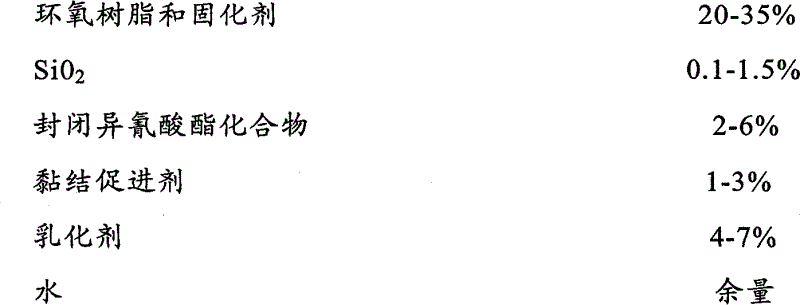

Method used

Image

Examples

Embodiment 1

[0041] Epoxy resin and curing agent 400g

[0042] SiO 2 15g

[0043] Adhesion Promoter 13g

[0044] Blocked isocyanate compound 40g

[0045] PVA aqueous solution 440g

[0046] water 340g

[0047] The above emulsion was coated on a 125-mesh nickel mesh, dried at 40°C, and heated at 140°C for 1 hour, then tested:

[0048] High-pressure water spray gun gunshot test: qualified; immersion test> 24h.

Embodiment 2

[0050] Epoxy resin and curing agent 300g

[0051] SiO 2 21g

[0052] Adhesion Promoter 42g

[0053]Blocked isocyanate compound 85g

[0054] PVA aqueous solution 770g

[0055] water 210g

[0056] The above emulsion is coated on a 105-mesh nickel mesh, dried at 40°C, and heated at 140°C for 40 minutes, then detected:

[0057] High-pressure water spray gun gunshot test: qualified; immersion test> 24h.

Embodiment 3

[0059] Epoxy resin and curing agent 400g

[0060] SiO 2 1.5g

[0061] Adhesion Promoter 28g

[0062] Blocked isocyanate compound 57g

[0063] PVA aqueous solution 630g

[0064] water 315g

[0065] The above emulsion was coated on a 80-mesh nickel mesh, dried at 40°C, and the adhesive film was cured at 140°C for 40 minutes. Detection:

[0066] High-pressure water spray gun gunshot test; qualified; immersion test> 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com