Water quality on-line monitoring method and system

A monitoring system and water quality technology, applied in the direction of testing water, instruments, and analyzing materials through chemical reactions, can solve the problems of lower measurement accuracy, long response time, and long time, so as to improve measurement accuracy and reduce measurement costs , to avoid the effect of cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

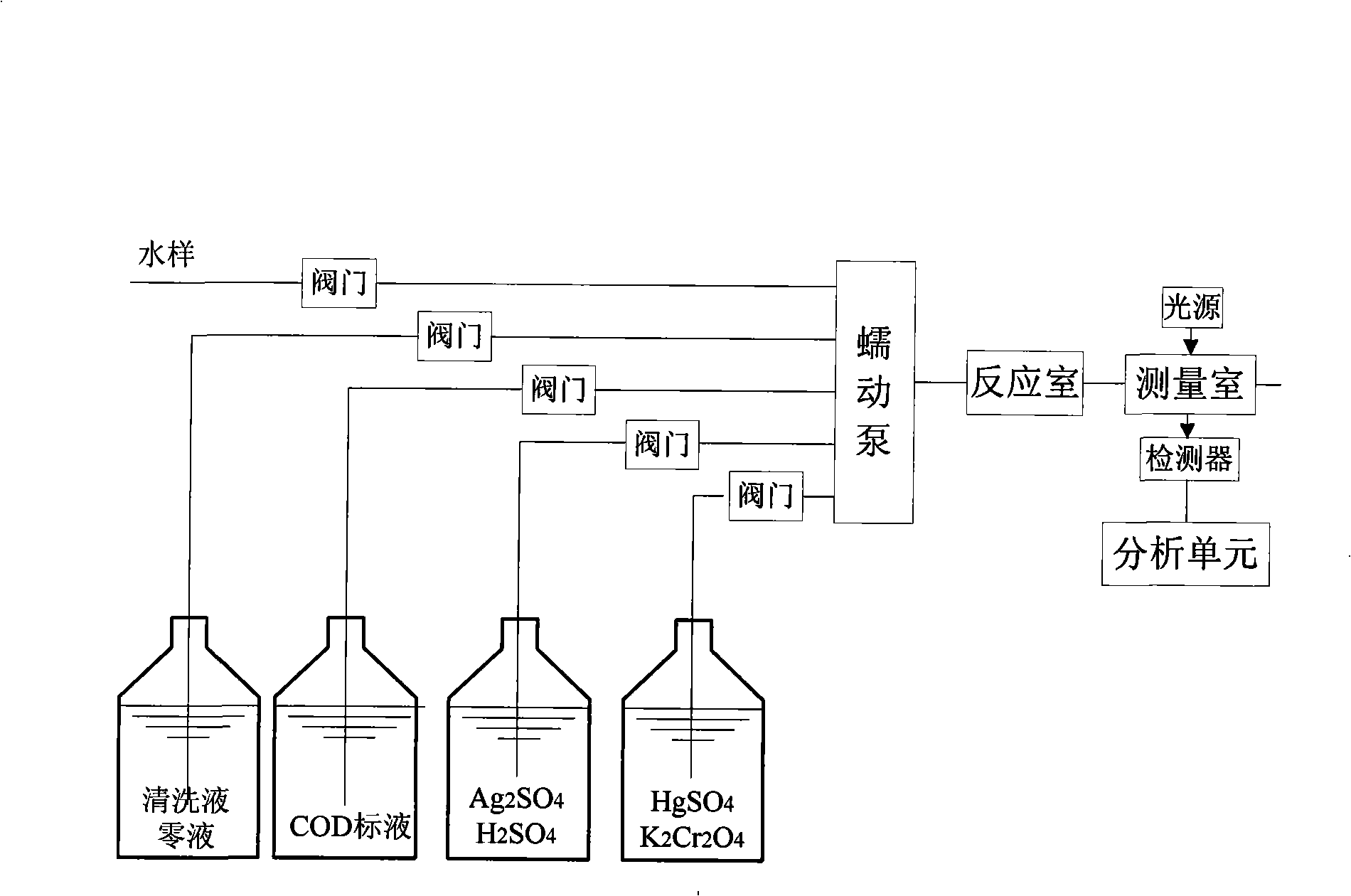

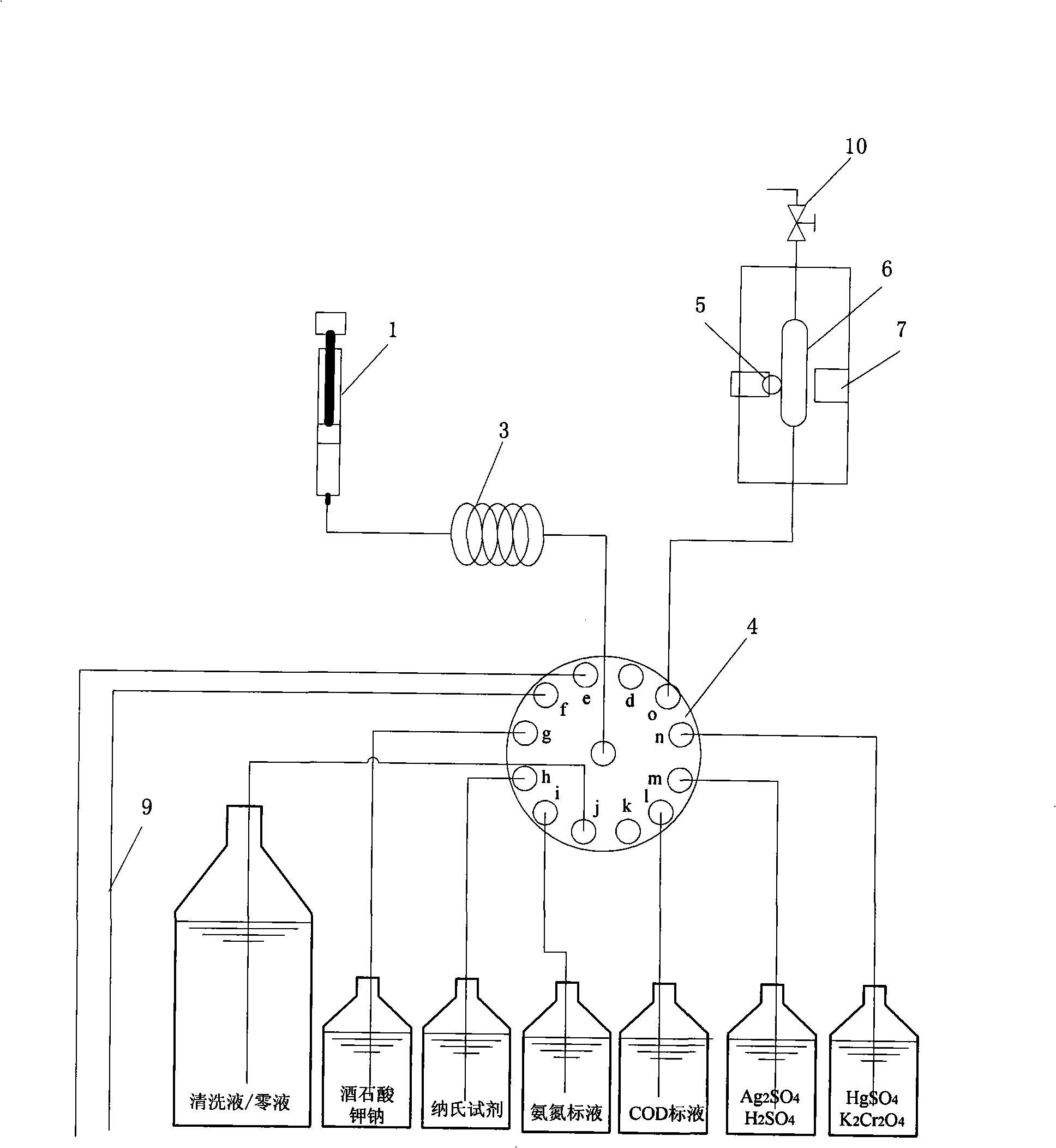

[0050] Such as figure 2 As shown, an online water quality monitoring system is used to measure ammonia nitrogen and COD in water samples. The monitoring system includes a syringe pump 1, a liquid storage ring 3, a multi-channel directional valve 4, and a reaction-detection unit.

[0051] One end of the syringe pump 1 is connected to the liquid storage ring 3 , and the volume of the liquid storage ring 3 is larger than that of the syringe pump 1 .

[0052] The multi-channel selector valve 4 has a sampling channel, a reagent channel connected to various reagents, an air channel d, an analysis channel o, a common channel connected to the liquid storage ring 3, a calibration channel connected to the calibration solution, and a waste channel f. The reagents include a shielding agent and a color developer for measuring ammonia nitrogen, a catalyst and an oxidant for measuring COD, and the calibration liquid is ammonia nitrogen standard liquid, COD standard liquid, ammonia nitrogen...

Embodiment 2

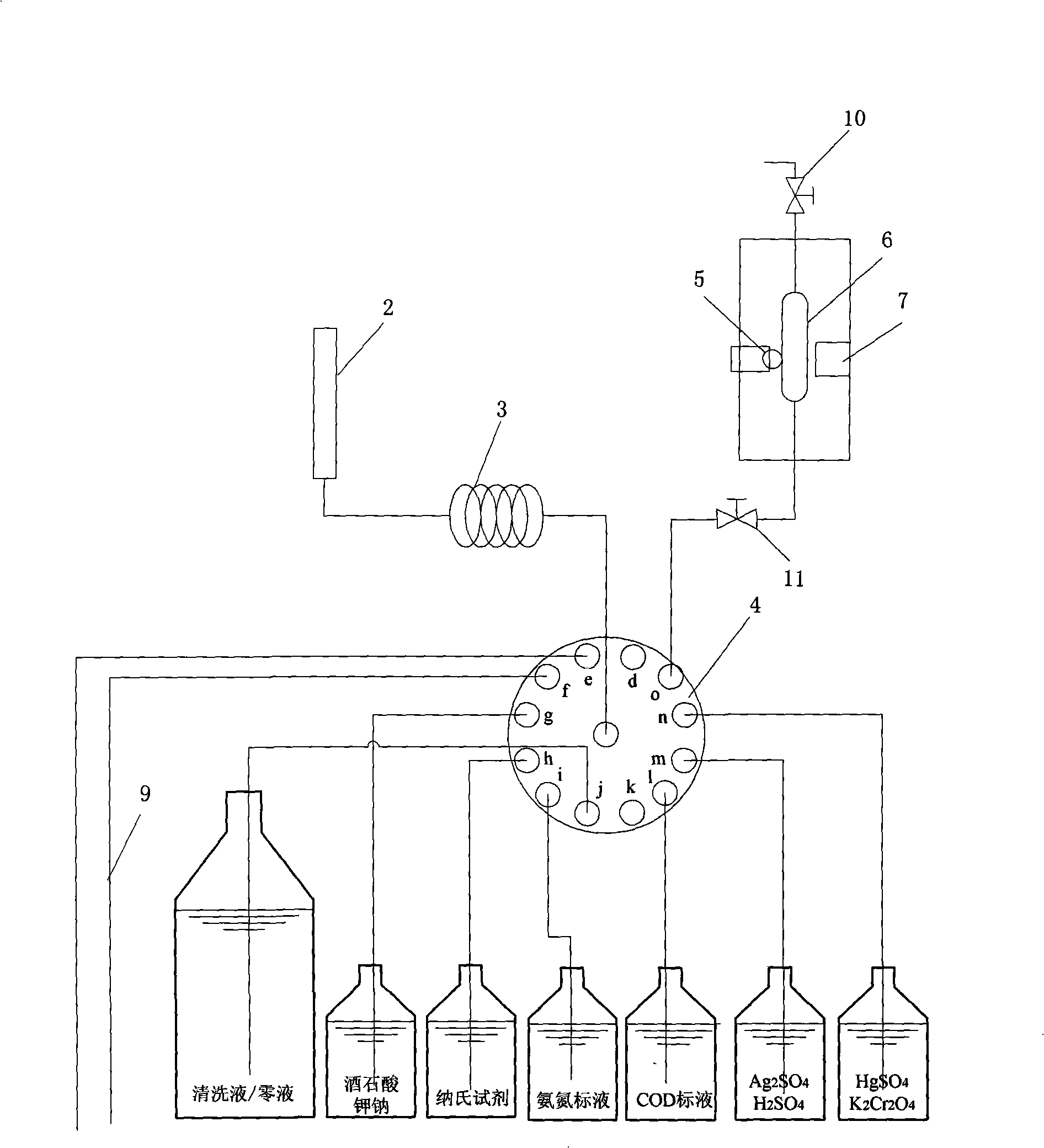

[0087] Such as image 3 Shown, a kind of water quality on-line monitoring system, is used for measuring ammonia nitrogen, COD in the water sample, and embodiment 1 difference is:

[0088] 1. Install a high pressure resistant second solenoid valve 11 between the reaction-detection chamber 6 and the analysis channel o.

[0089] 2. Use plunger pump 2 instead of syringe pump 1.

[0090] 3. A microwave heating device is installed on the reaction-detection chamber 6 to replace the original electric heating device.

[0091] This embodiment also discloses a water quality online monitoring method, comprising the following steps:

[0092] a, the multi-channel selector valve 4 selects the sampling channel e and the reagent channel n respectively, and then the plunger pump 2 draws the water sample to be measured and the part of the reagent used for measuring COD ( Mercury sulfate, potassium dichromate solution);

[0093] b. The multi-channel selector valve 4 selects the analysis chann...

Embodiment 3

[0121] Such as Figure 4 Shown, a kind of water quality on-line monitoring system is used for measuring ammonia nitrogen, COD in the water sample, and embodiment 2 is different:

[0122] 1. Air passages are no longer provided on the multi-channel directional valve 4 .

[0123] 2. One end of the plunger pump 2 is connected to a three-way valve 15, and a channel 12 of the three-way valve 15 is connected to the outside world as an air channel; one end of the liquid storage ring 3 is connected to the three-way valve 15.

[0124] This embodiment also discloses a water quality online monitoring method, comprising the following steps:

[0125] a, the multi-channel selector valve 4 selects the sampling channel e and the reagent channel n respectively, and then the plunger pump 2 draws the water sample to be measured and the part of the reagent used for measuring COD ( Mercury sulfate, potassium dichromate solution);

[0126] b. The multi-channel selector valve 4 selects the analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com