Subway shield tunnel enlarging station special area and station structure connecting method

A technology of subway shield and shield segment, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of insufficient efficiency of shield machines, and achieve the effect of reducing deformation and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

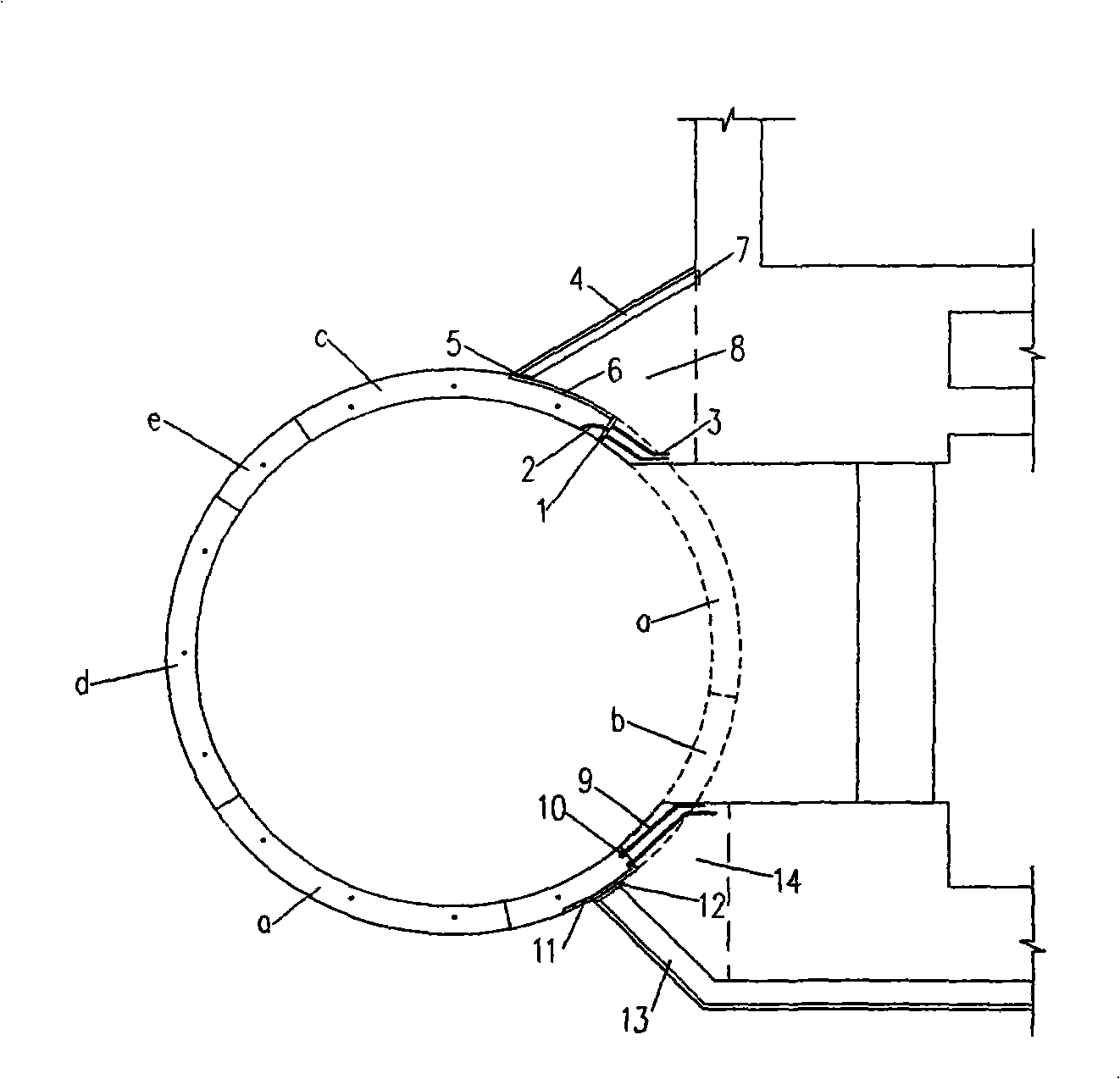

[0017] Such as figure 1 As shown, this is the connection form of the special shield segment of the column station and the station structure. The column station consists of longitudinal beams and columns to form a structural load-bearing system, which is the station form commonly used in open-cut and underground-cut stations of subways. Its construction steps are as follows:

[0018] 1. The construction of the shield interval passes through the station, and the shield segment within the station adopts the special segment structure of the present invention, that is, the segments are connected clockwise: 1 standard A type a, 1 cut A type b, 1 block Standard A type a, 1 piece B2 type d, 1 piece C type e and 1 piece B1 type c. When expanding to form a station, one standard A-type segment a should be removed, and one cut A-type segment b should be cut to form an opening leading to the station platform. The dotted line in the figure indicates the removed segment. In order to facili...

Embodiment 2

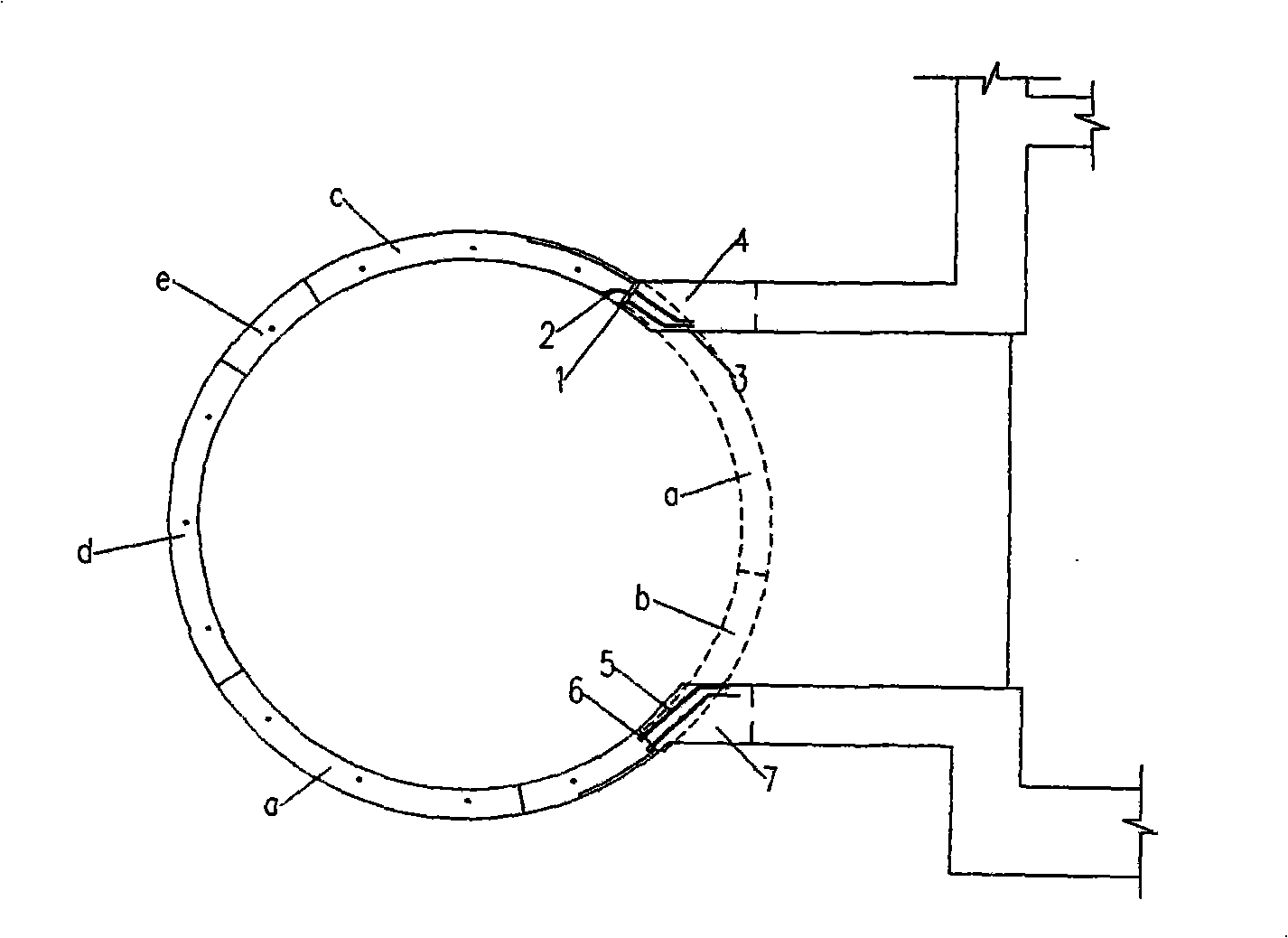

[0023] Example 2: The connection form between the special shield segment of the tower station and the station structure is as follows figure 2 shown. The tower-pillar station does not have longitudinal beams and columns, and the station has cross passages at intervals to connect the platform side and the platform as a passage for passengers to get on and off the train. This type of station can be used for both open-cut and underground-cut stations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com