Process for preparing metallic titanium and titanium master alloy

A technology of titanium-based alloy and metal titanium is applied in the field of non-ferrous metal metallurgical molten salt electrolysis, which can solve the problems of chlorine pollution, low current efficiency and high production cost of metal titanium, shorten the process flow, reduce production cost and improve labor efficiency. Effect

Inactive Publication Date: 2008-10-22

曹大力 +1

View PDF0 Cites 45 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

2.1 Medium-temperature electrolysis: use alkali metal or alkaline earth metal chloride as electrolyte, electrolysis temperature is 600-1000°C, electrolyze TiCl4 under the protection of inert gas, but there are problems such as low solubility of TiCl4 in molten salt, low current efficiency, and generation of Chlorine gas pollutes the environment, metal powder is easy to oxidize and other technical problems cannot be industrialized, etc.

2.2 High-temperature electrolysis: When the temperature is higher than 1700°C, titanium (melting point 1943K) becomes liquid, which can realize continuous production like electrolytic aluminum, and the purity of metal titanium is relatively high, but the production conditions are relatively harsh

However, the most effective production process for extracting titanium metal is the Kroll method. Due to the widespread use of the Kroll method, the high production cost of titanium metal affects its application.

Method used

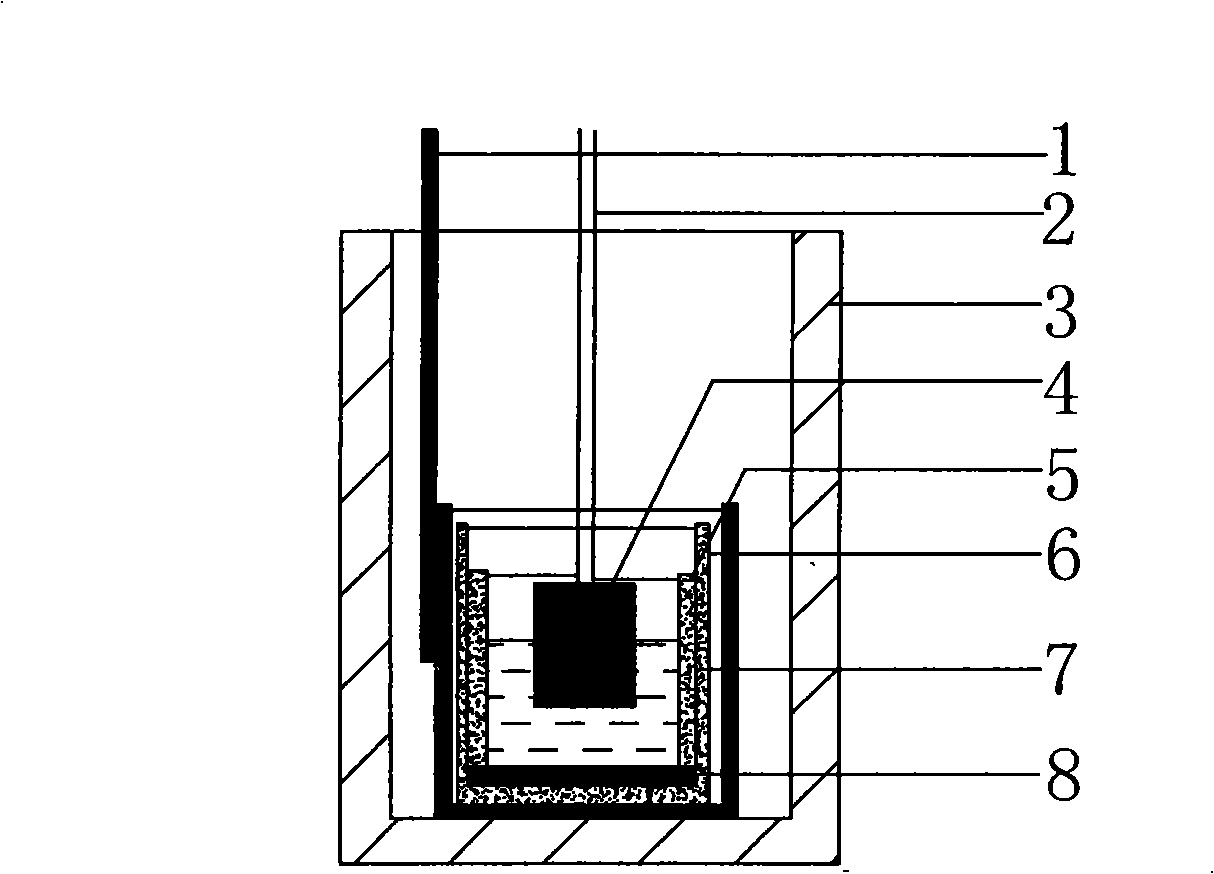

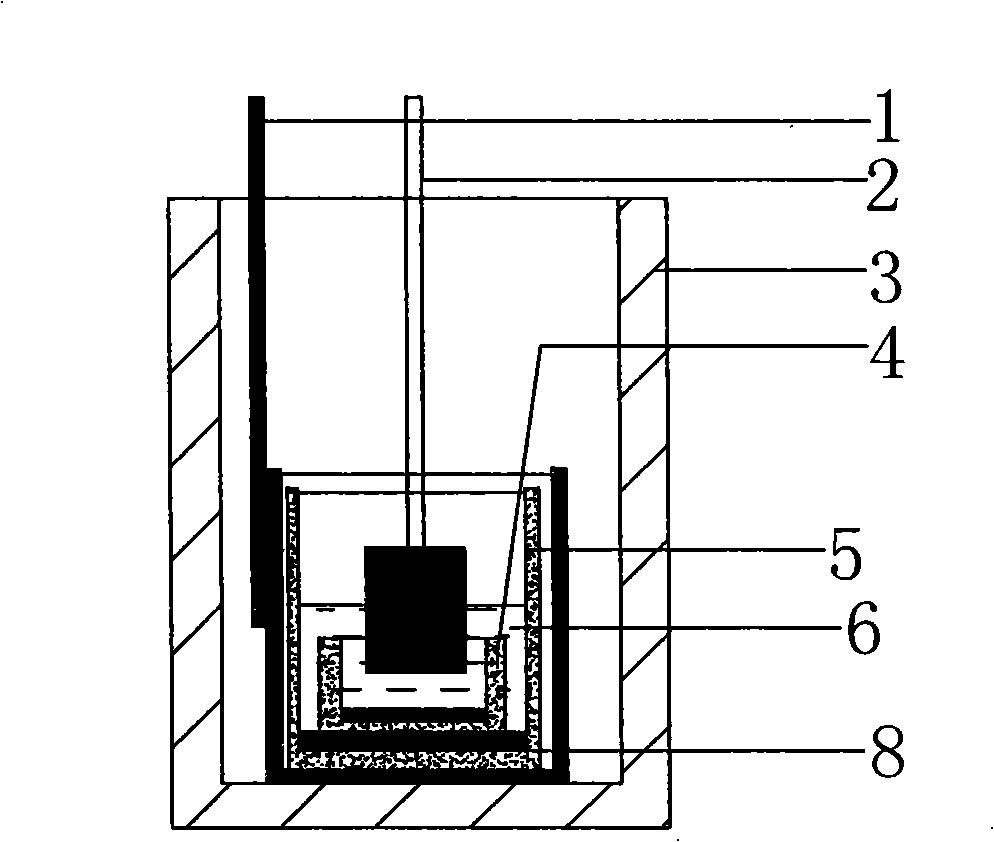

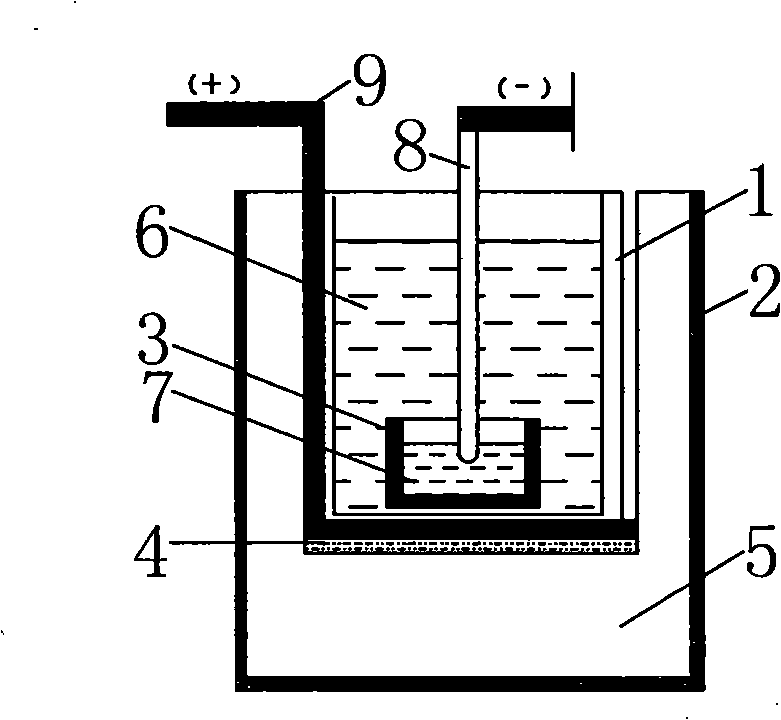

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

example 2

example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the non-ferrous metal metallurgy fused salt electrolysis field, a method mainly comprises the steps of: preparing titanium dioxide, titanium tetrachloride, titanium dichloride and fluotitanate as raw materials, electrolyzing one or a plurality of combinations of TiO2, TiC14 and the fluotitanate in an electrolysis bath, preparing metallic titanium or titanium-based master alloy through an electrolysis method or a thermal reduction-electrolysis combined method, performing the TiO2 and connecting direct current to deoxidize or adopting metal (or metallic compound) for heat reducing the TiO2 beforehand, preparing the metallic titanium which contains oxygen (O) with certain concentration, and then electrolyzing aluminium, alkali metal, alkaline earth, rare earth metal, metallic copper, metallic zinc or metallic lead to deoxidize finally in the electrolysis bath. The purpose of the method is to reduce the production cost of the metallic titanium, simplify the production procedures and lower the environmental pollution in the production process, especially the titanium dioxide taken as the raw materials, the production flow is shortened, the storage and the transportation are convenient, none chlorine gas takes part in the reaction, and green metallurgy of the metallic titanium can be realized.

Description

Methods for preparing titanium metal and titanium-based alloys Technical areas: The invention relates to the field of non-ferrous metal metallurgy molten salt electrolysis. The method uses mainly developed titanium dioxide, titanium tetrachloride, titanium dichloride and fluorotitanate as raw materials, and electrolyzes TiO2, TiCl4 and fluorotitanate in an electrolytic cell. One or more combinations to prepare metallic titanium or titanium-based master alloy; or use metal (or metal compound) to pre-thermally reduce TiO2 to prepare metallic titanium containing a certain concentration of oxygen (O), and then electrolyze in an aluminum electrolytic cell Perform final deoxygenation. Background technique: Titanium has the advantages of low density, high specific strength, oxidation resistance, fatigue resistance, corrosion resistance, etc. It is an excellent structural and functional material and enjoys the reputation of "all-round metal" and "rare giant heading into the 21st c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25C3/28

Inventor 曹大力王吉坤

Owner 曹大力

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com