High intensity gas shielded welding wire, wire rod and application thereof

A gas-shielded welding wire and wire rod technology, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of unfavorable welding, increase crack sensitivity coefficient, increase production cost, etc., achieve excellent mechanical properties, reduce crack sensitivity coefficient, The effect of economical improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] According to the composition design of the present invention, the production of welding wire wire rod is carried out, and the process includes: 1) converter; 2) refining; 3) die casting; 4) steel ingot rolling; 5) controlled rolling and cooling of steel billet; 6) spinning; 7) Collection; 8) Inspection; 9) Packaging. The production process of welding wire is as follows: 1) incoming inspection of wire rod; 2) rough drawing process; 3) copper plating process; 4) fine drawing process; 5) coil packaging process. The chemical composition of the deposited metal of the obtained welding wire is shown in Table 3, and the mechanical properties are shown in Table 8.

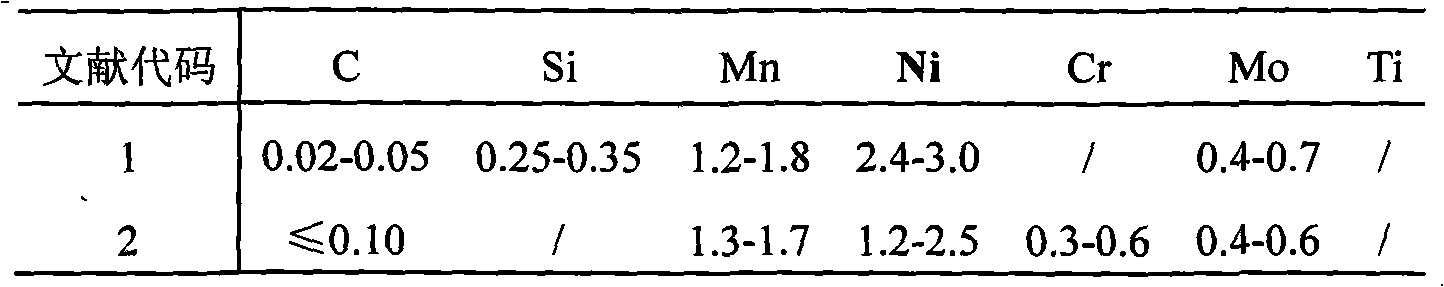

[0046] The finished product chemical composition (wt%) of table 3 embodiment 1 welding wire

[0047]

Embodiment 2

[0049] Production technology is identical with embodiment 1. The chemical composition of the deposited metal of the obtained welding wire is shown in Table 4, and the mechanical properties are shown in Table 8.

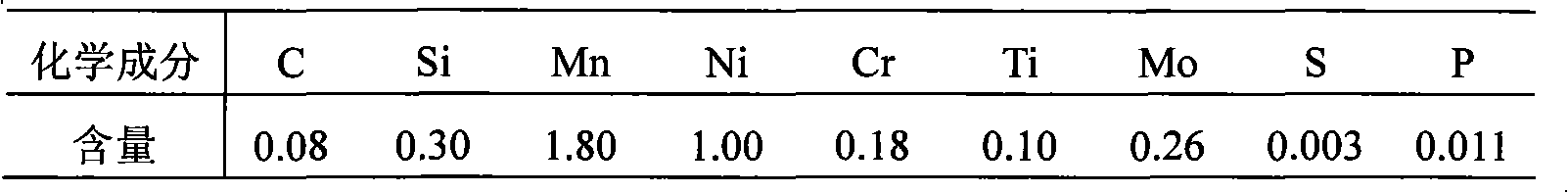

[0050] The finished product chemical composition (wt%) of table 4 embodiment 2 welding wire

[0051]

Embodiment 3

[0053] Production technology is identical with embodiment 1. The chemical composition of the deposited metal of the obtained welding wire is shown in Table 5, and the mechanical properties are shown in Table 8.

[0054] The finished product chemical composition (wt%) of table 5 embodiment 3 welding wire

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com