Electro-magnetic shielding material of tin-nickel alloy and preparing method thereof

An electromagnetic shielding material, tin-nickel alloy technology, applied in the direction of magnetic/electric field shielding, electrical components, fiber types, etc., can solve the problems restricting the application of textiles, etc., and achieve good electromagnetic shielding properties, good decorative effects, and excellent electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

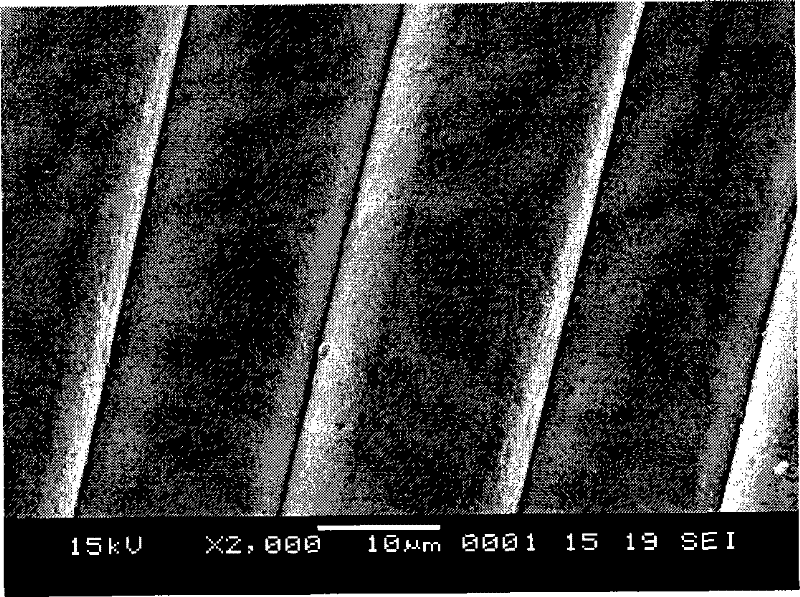

[0034] In this embodiment, the copper-plated nylon cloth produced by Sanyuan Electronic Technology Co., Ltd. is used as the substrate, and the steps are as follows: the first step is pretreatment. Use 3moL / L chromic acid solution to degrade to remove oxides and dirt on the surface of fabric fibers after electroless copper plating;

[0035] The second step is to wash with water. Wash off the residual acid and heavy metal ions on the fabric with water;

[0036] The third step is electroplating. Using nickel anode, the following formula is used to prepare tin-nickel electroplating solution:

[0037] Potassium pyrophosphate K 4 P 2 o 7 ·3H 2 O 150g / L

[0038] Nickel Sulfate NiSO 4 ·6H 2 O 30g / L

[0039] Stannous Chloride SnCl 2 2H 2 O 7.5g / L

[0040] Ammonium chloride NH 4 Cl 10g / L

[0041] Glycine C 2 h 5 NO 2 10g / L

[0042] pH 8~9

[0043] Temperature 25~30℃

[0044] Cathode current 0.67~1A / dm 2

[0045] Plating time 480s

[0046] Through the abov...

Embodiment 2

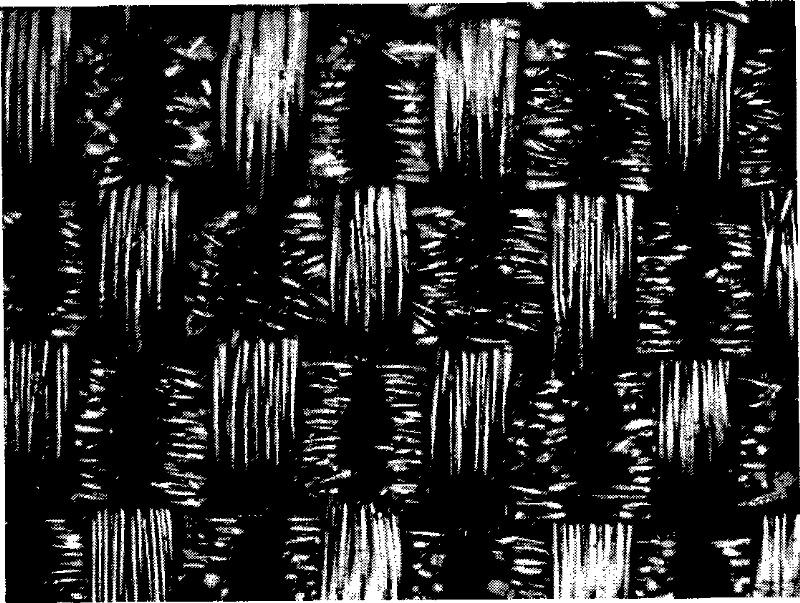

[0050] In this example, the copper-plated nylon cloth produced by Sanyuan Electronic Technology Co., Ltd. is used as the base material, and the steps are as follows:

[0051] The first step is preprocessing. Use 3moL / L chromic acid solution to degrade to remove oxides and dirt on the surface of fabric fibers after electroless copper plating;

[0052] The second step is to wash with water. Wash off the residual acid and heavy metal ions on the fabric with water;

[0053] The third step is electroplating. Using nickel anode, the following formula is used to prepare tin-nickel electroplating solution:

[0054] Potassium pyrophosphate K 4 P 2 o 7 ·3H 2 O 150g / L

[0055] Nickel Sulfate NiSO 4 ·6H 2 O 30g / L

[0056] Stannous Chloride SnCl 2 2H 2 O 7.5g / L

[0057] Ammonium chloride NH 4 Cl 10g / L

[0058] L-cysteine C 3 h 7 NO 2 S 5g / L

[0059] pH 8~9

[0060] Temperature 25~30℃

[0061] Cathode current 0.67~1A / dm 2

[0062] Plating time 480s

[0063] Throug...

Embodiment 3

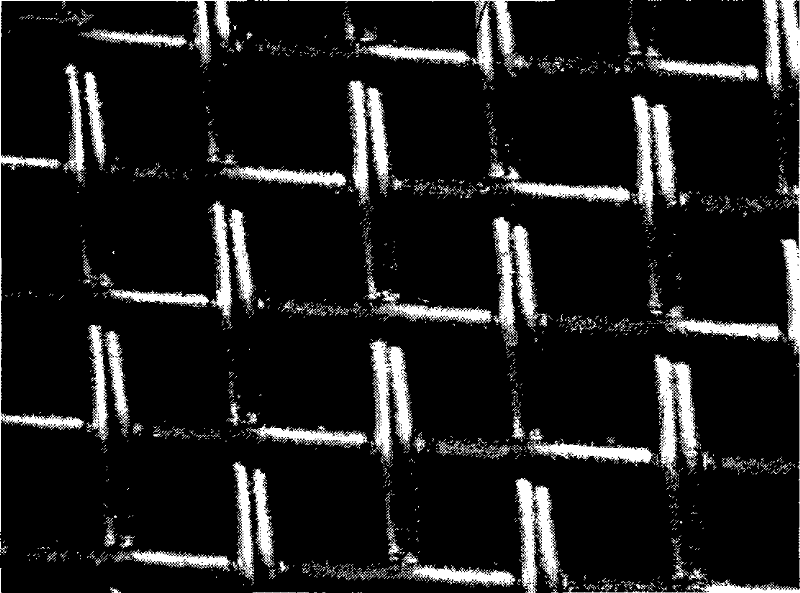

[0067] In this example, the copper-plated mesh cloth MF36 produced by Sanyuan Electronic Technology Co., Ltd. is used as the base material, and the steps are as follows:

[0068] The first step is preprocessing. Use 3moL / L chromic acid solution to degrade to remove oxides and dirt on the surface of fabric fibers after electroless copper plating;

[0069] The second step is to wash with water. Wash off the residual acid and heavy metal ions on the fabric with water;

[0070] The third step is electroplating. Using nickel anode, the following formula is used to prepare tin-nickel electroplating solution:

[0071] Potassium pyrophosphate K 4 P 2 o 7 ·3H 2 O 150g / L

[0072] Nickel Sulfate NiSO 4 ·6H 2 O 30g / L

[0073] Stannous Chloride SnCl 2 2H 2 O 7.5g / L

[0074] Ammonium chloride NH 4 Cl 10g / L

[0075] Glycine C 2 h 5 NO 2 5g / L

[0076] pH 8~9

[0077] Temperature 25~30℃

[0078] Cathode current 0.67~1A / dm 2

[0079] Plating time 480s

[0080]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com