Process for preparing micro-coiled carbon fiber/Ni composite material by chemical nickel plating

A technology of electroless nickel plating and composite materials, which is applied in the field of electroless nickel plating to prepare micro-helical carbon fiber/Ni composite materials, which can solve problems such as difficult to solve the uniformity of the plating layer and affect the application of micro-helical carbon fiber composite materials, so that it is not easy to deteriorate , easy to operate, and stable plating solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

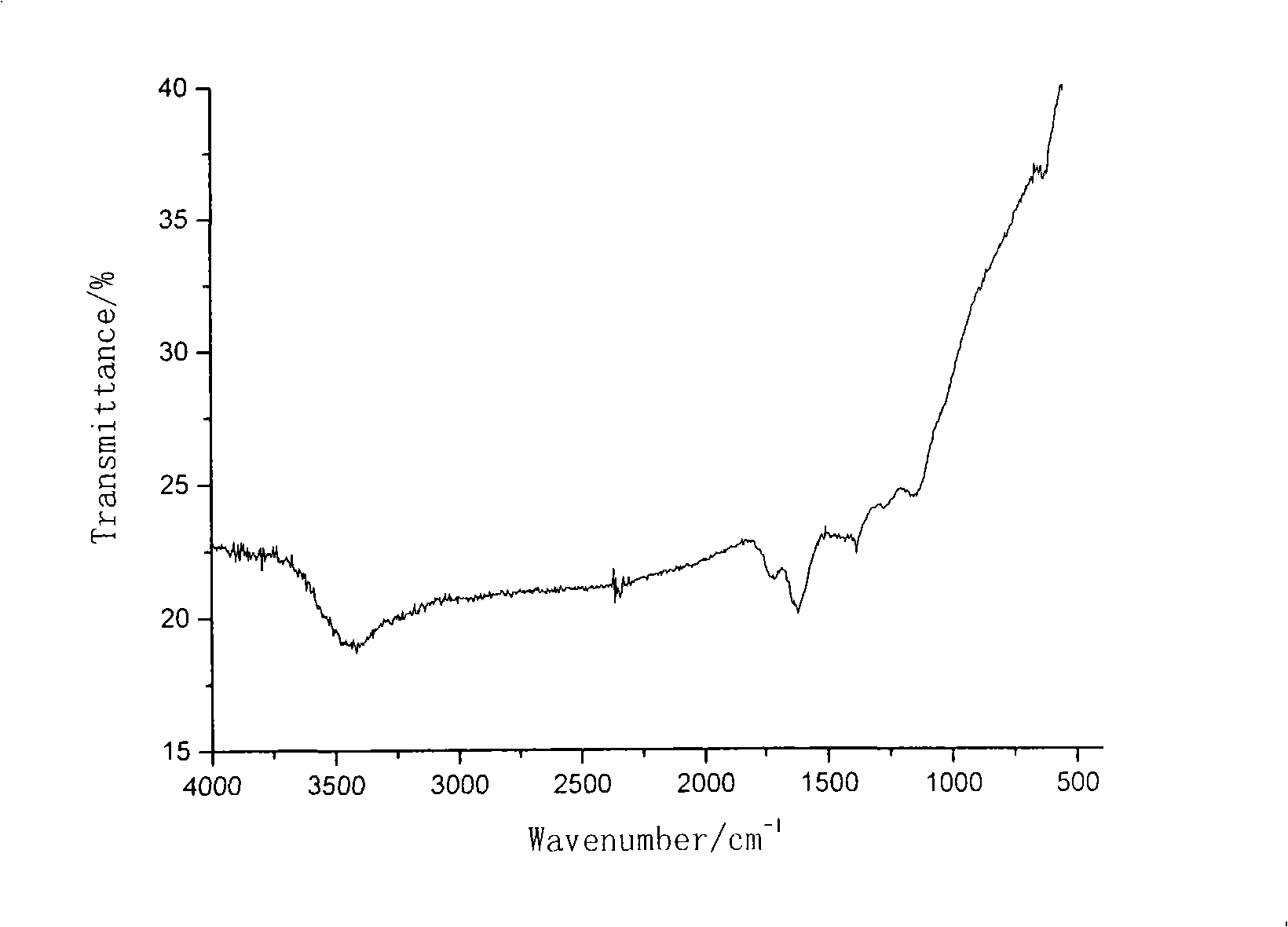

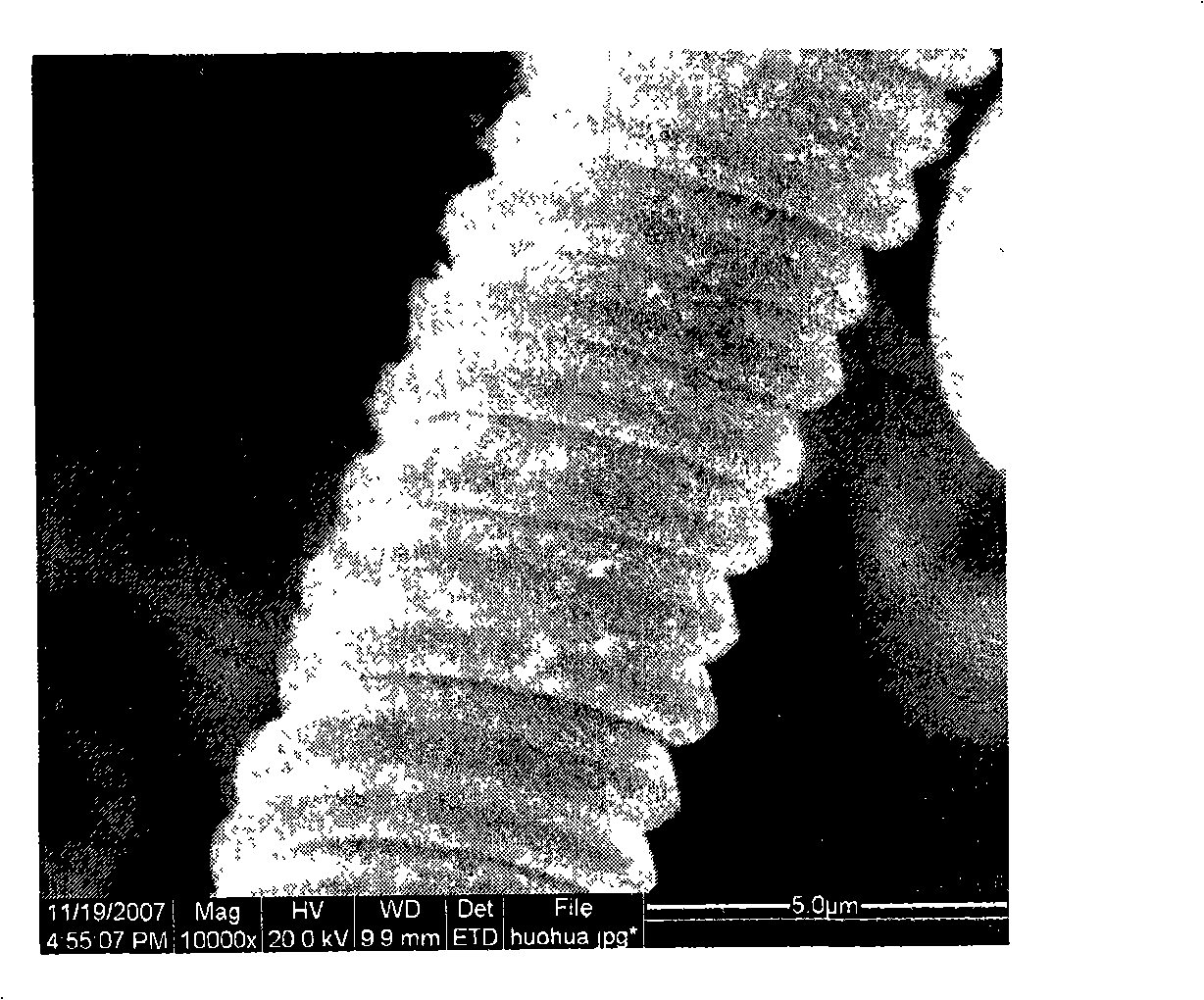

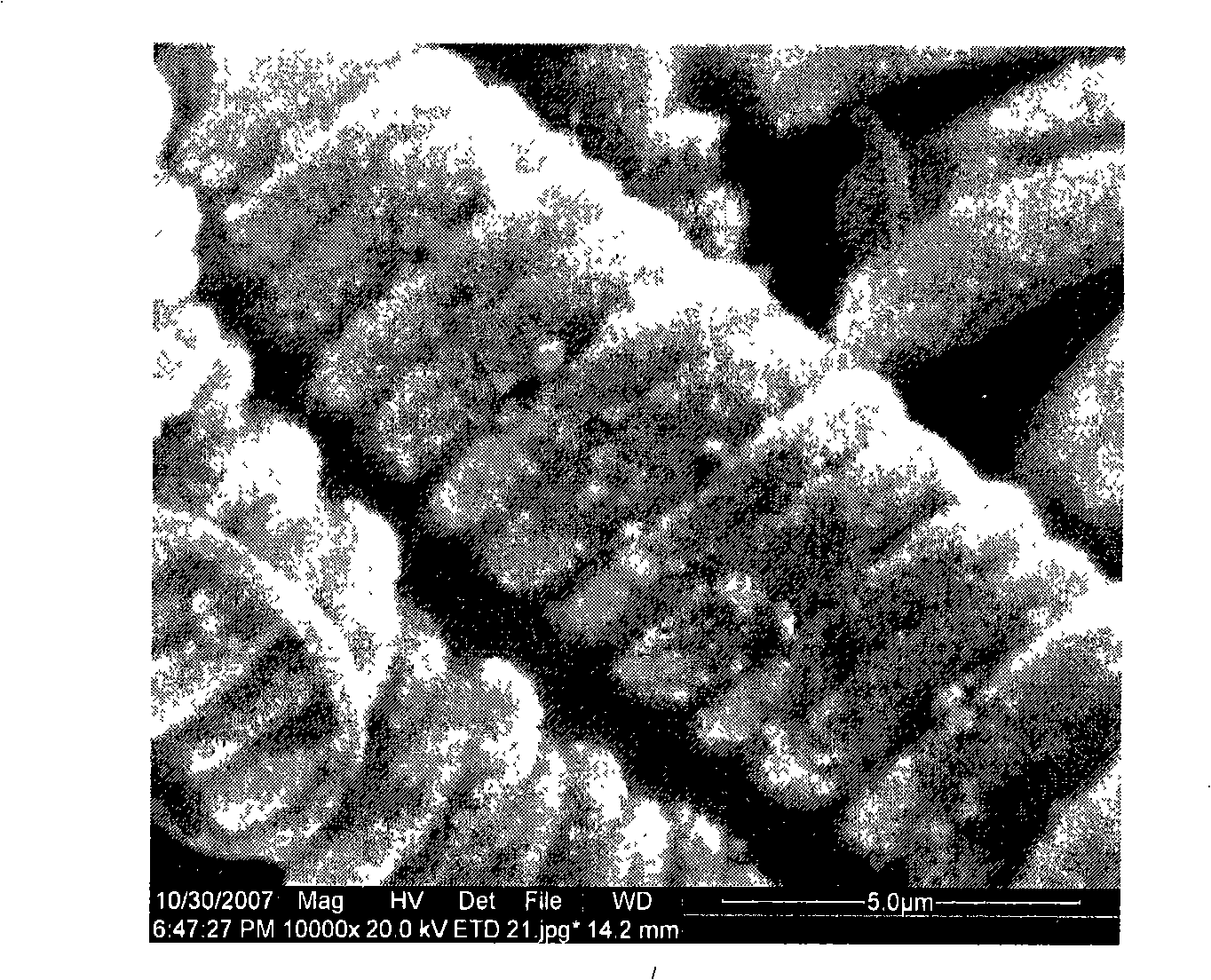

[0028] (1) Use a high-power ultrasonic disperser to disperse the micro-helical carbon fiber particles to a diameter of 2-8 μm and a length of 10-100 μm to obtain a micro-helical carbon fiber in the form of powder. Weigh 1g of micro-helical carbon fiber into 100ml concentrated nitric acid, and add magnetic stirring to roughen it, take it out after 72h, and rinse it with deionized water to neutral to obtain micro-helical carbon fiber with clean and rough surface particles.

[0029] (2) Put the roughened micro-spiral carbon fiber into 30g / L SnCl 2 , in 60ml / L concentrated hydrochloric acid solution, sensitized by ultrasonic vibration at room temperature for 30min, and washed until neutral.

[0030] (3) Add the sensitized microhelical carbon fiber to 0.5g / L PdCl 2 , 10ml / L concentrated hydrochloric acid solution, activated by ultrasonic vibration at room temperature for 30min, washed until neutral, and dried.

[0031] (4) According to 20g of nickel sulfate, 20g of sodium hypoph...

Embodiment 2

[0034] (1) Weigh 1 g of the micro-helical carbon fiber particles prepared in Example 1, put them into 100 ml of concentrated sulfuric acid, and stir them with a magnetic force to coarsen them, take them out after 24 hours, rinse them with deionized water, and dry them.

[0035] (2) Put the roughened micro-spiral carbon fiber into 50g / L SnCl 2 , in 80ml / L concentrated hydrochloric acid solution, sensitized by ultrasonic vibration at room temperature for 10min, and washed until neutral.

[0036] (3) Add the sensitized microhelical carbon fiber to 1.0g / L PdCl 2 , in 30ml / L concentrated hydrochloric acid solution, activated by ultrasonic vibration at room temperature for 10min, washed until neutral, and dried.

[0037] (4) According to 30g of nickel sulfate, 25g of sodium hypophosphite, 20g of ammonium chloride, 60g of sodium citrate, 80mg of surfactant sodium dodecylbenzenesulfonate, 10mg of stabilizer thiourea, prepare 1000ml of plating solution, pH The value is adjusted to ab...

Embodiment 3

[0040] (1) Weigh 1 g of the microhelical carbon fiber particles prepared in Example 1 and put them into 100 ml of mixed acid (concentrated nitric acid:concentrated sulfuric acid: 3:1), and magnetically stir for 12 hours, rinse with deionized water, and dry.

[0041] (2) Put the roughened micro-spiral carbon fiber into 10g / L SnCl 2 , in 20ml / L concentrated hydrochloric acid solution, sensitized by ultrasonic vibration at room temperature for 60min, and washed until neutral.

[0042] (3) Add the sensitized microhelical carbon fiber to 0.1g / L PdCl 2 , 50ml / L concentrated hydrochloric acid solution, activated by ultrasonic vibration at room temperature for 60min, rinsed until neutral, and dried.

[0043] (4) According to nickel sulfate 40g, sodium hypophosphite 40g, ammonium chloride 50g, sodium citrate 100g, surfactant sodium dodecylbenzene sulfonate 50mg, stabilizer thiourea 1mg, prepare the plating solution 1000ml, pH The value is adjusted to about 8.0 with ammonia water or 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com