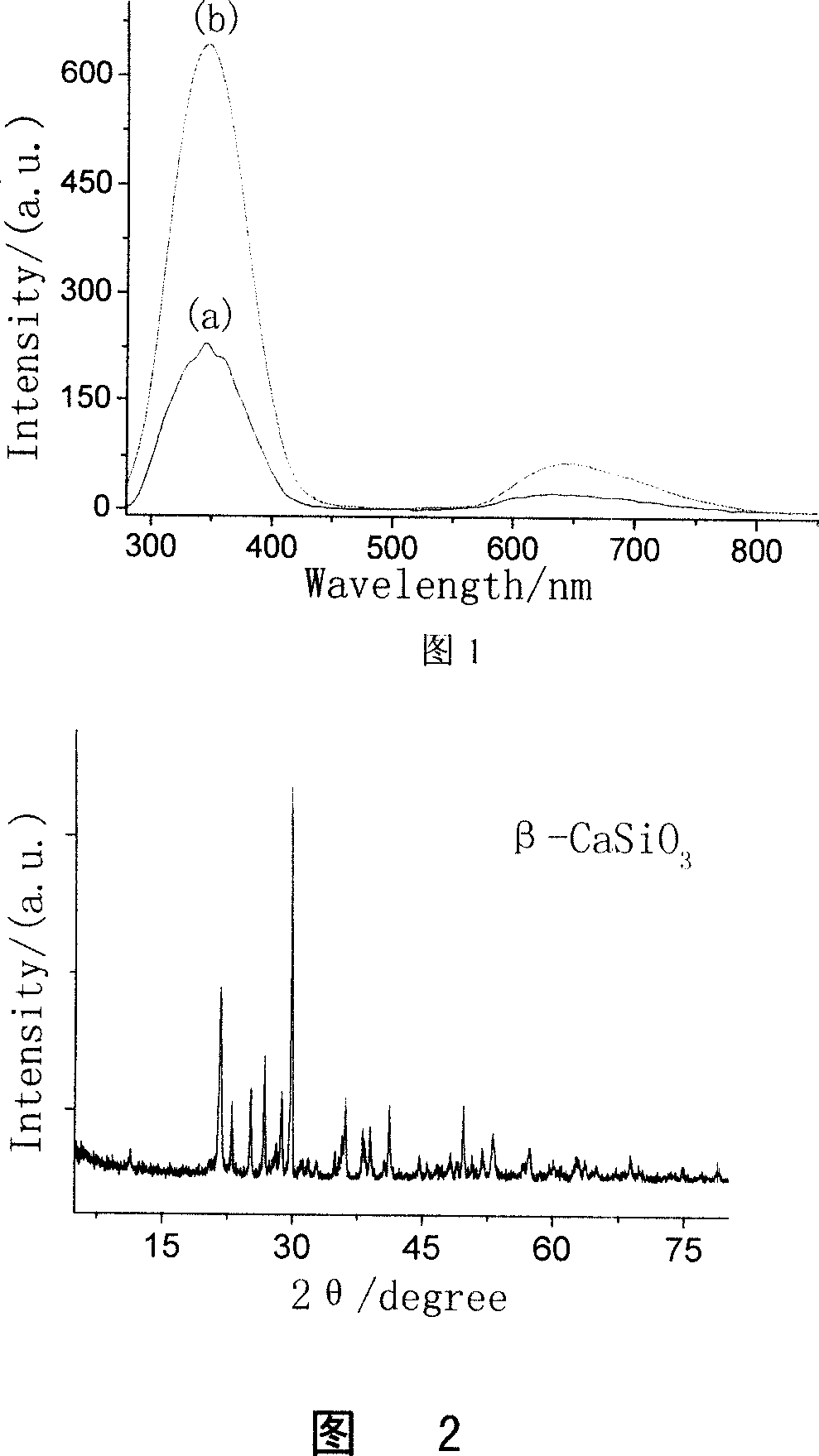

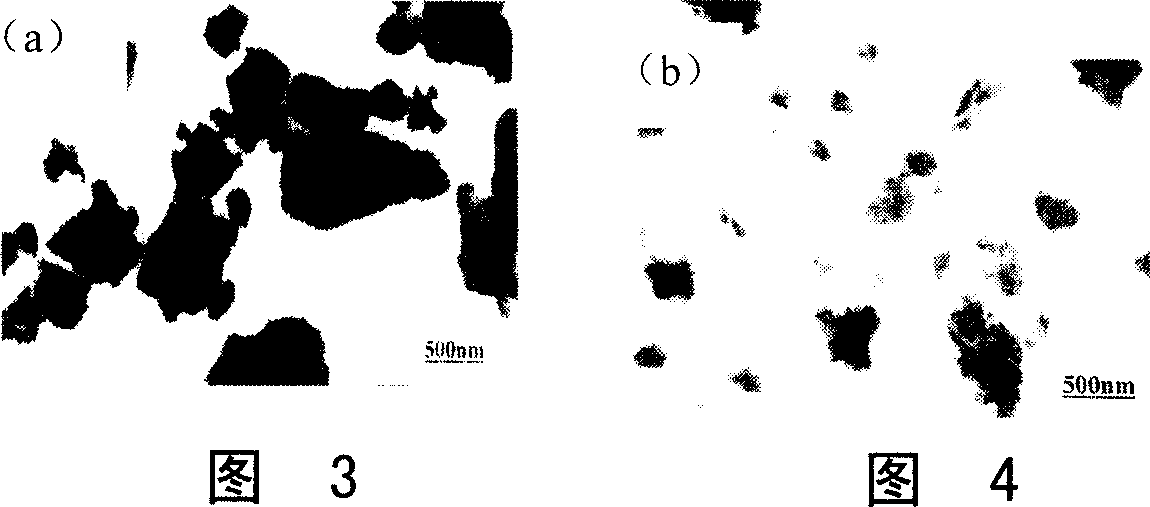

Nano red CaSiO3:Pb, Mn fluorescent material and its preparing method

A red fluorescent and nanotechnology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of large product particle size, high energy consumption, low luminous intensity, etc., and achieve improved microstructure, increased fluorescence intensity, and excellent application performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 3.2971g Ca(NO 3 ) 2 , 0.1656g Pb(NO 3 ) 2 and 0.2706g Mn(NO 3 ) 2 , add 0.1mL nitric acid and 5mL deionized water, stir and dissolve in the beaker and slowly pour in 1.5622g SiO 2 Add 1mL ON70 to the sol made of aerosol and 40mL ethanol, stir in a water bath at 40°C for 15min, then let it stand for 12h, and then dry the formed gel at 50°C for 5h to obtain the phosphor precursor, and transfer the precursor to Put it into a corundum crucible, slowly raise the temperature and bake in air at 900°C for 2 hours, then bake at 1200°C for 4 hours, take it out after cooling, and grind it evenly to get the sample.

Embodiment 2

[0023] Weigh 3.2971g Ca(NO 3 ) 2 , 0.1656g Pb(NO 3 ) 2 and 0.2706g Mn(NO 3 ) 2 , add 0.1mL nitric acid and 5mL deionized water, stir and dissolve in the beaker and slowly pour in 1.5622g SiO 2 Add 1mL T08 to the sol made of aerosol and 40mL ethanol, stir in a water bath at 40°C for 15min, then let it stand for 12h, then dry the formed gel at 50°C for 5h to obtain the phosphor precursor, transfer the precursor to Put it into a corundum crucible, slowly raise the temperature and bake in air at 900°C for 2 hours, then bake at 1200°C for 4 hours, take it out after cooling, and grind it evenly to get the sample.

Embodiment 3

[0025] Weigh 3.2971g Ca(NO 3 ) 2 , 0.1656g Pb(NO 3 ) 2 and 0.2706g Mn(NO 3 ) 2 , add 0.1mL nitric acid and 5mL deionized water, stir and dissolve in the beaker and slowly pour in 1.5622g SiO 2 Add 1mL XL80 to the sol made of aerosol and 40mL ethanol, stir in a water bath at 40°C for 15min, then let it stand for 12h, then bake the formed gel at 50°C for 5h to obtain the phosphor precursor, and transfer this precursor into For the corundum crucible, heat up slowly at 900°C for 2 hours in air, then bake at 1200°C for 4 hours, take it out after cooling, and grind it evenly to get the sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com