Heating element and heating apparatus for nano electric heating membrane

A nano-electric heating film and heating element technology, which is applied in heating element materials, energy-saving heating/cooling, liquid chemical plating, etc., can solve the problems of few types of electric heating film heating tubes, limited application of heating devices, and complex coating solution formulations. To achieve the effect of high product quality, easy operation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare the coating solution according to the following raw material formula and weight ratio: the coating solution is 35% of tin tetrachloride, 12% of antimony trichloride, 8% of glycerin, and the rest is solvent.

Embodiment 2

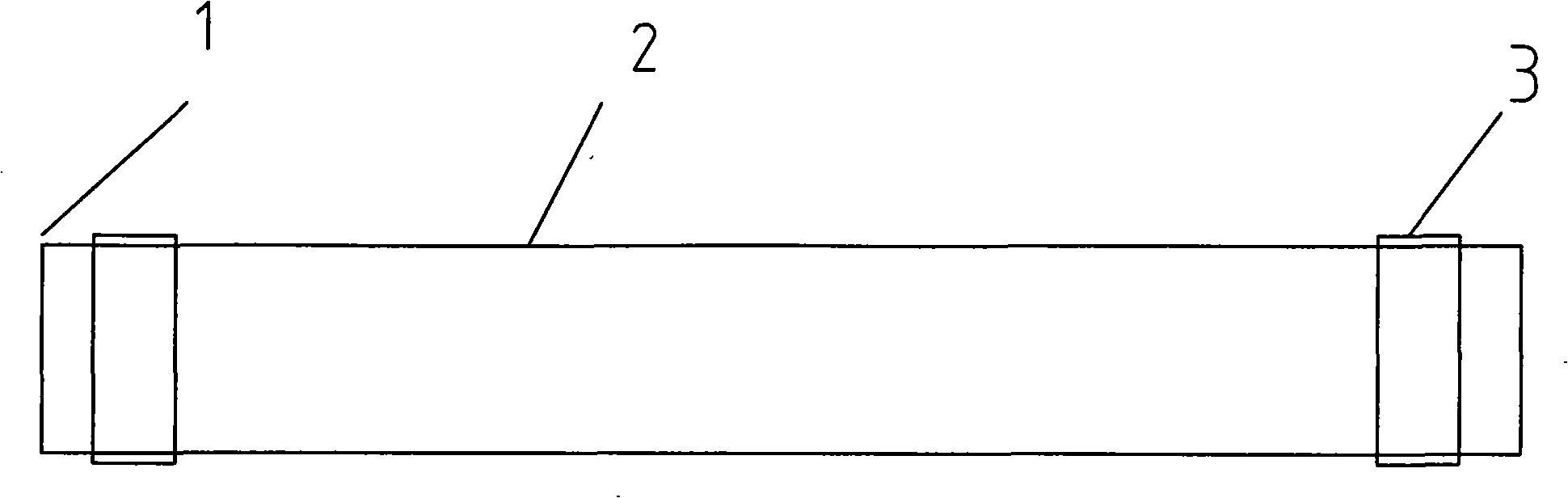

[0029] Adopt the coating liquid of embodiment 1 preparation to produce nano electric heating film heating element:

[0030] The first step of spray film:

[0031] Put the prepared component base material into the coating furnace whose temperature has reached about 400 degrees, close the furnace door, and when the temperature rises to the set temperature of 700 degrees, spray the coating solution into the furnace, and take it out after the power reaches the required range Cool the components to room temperature;

[0032] Step 2: Apply sintered electrodes:

[0033] The electrode should be applied to the appropriate position with the electric heating film. Use a screen printing machine or manual operation, and put it into the baking plate furnace when it is slightly dry. When the temperature reaches the set temperature of 500-600 ° C, keep the temperature for 15 minutes, take it out and cool it. , which is the nanometer electrothermal film heating element. The resulting produc...

Embodiment 3

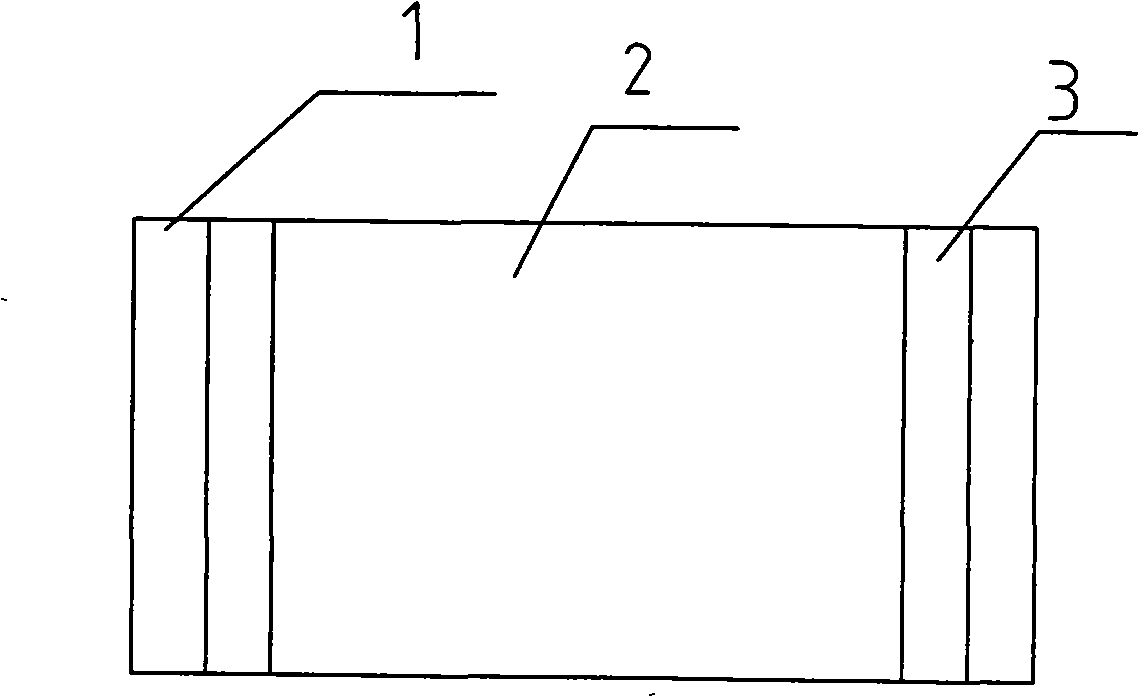

[0035] The first step and the second step are the same process as in Example 2 to manufacture the nano-electrothermal film heating element, and the third step is to make the electrode card or the lead wire: when the pipe is used as the electrode card, it is cut from thin plates such as stainless steel, copper plated with silver, and phosphor copper. A strip of appropriate length and width, with holes punched at both ends of the metal strip, is fastened on the electrode 3 with screws.

[0036] can also be as Image 6 Copper-tinned conductive braid is used, and cold-rolled terminals are riveted on both ends as the lead wire 4, and then fastened to the electrode by screws or welded to the electrode 3.

[0037] Such as Figure 5 As shown, plate-shaped or special-shaped components are used, and the lead-out wire 4 is compressed by welding, riveting or drilling, and fastened with screws.

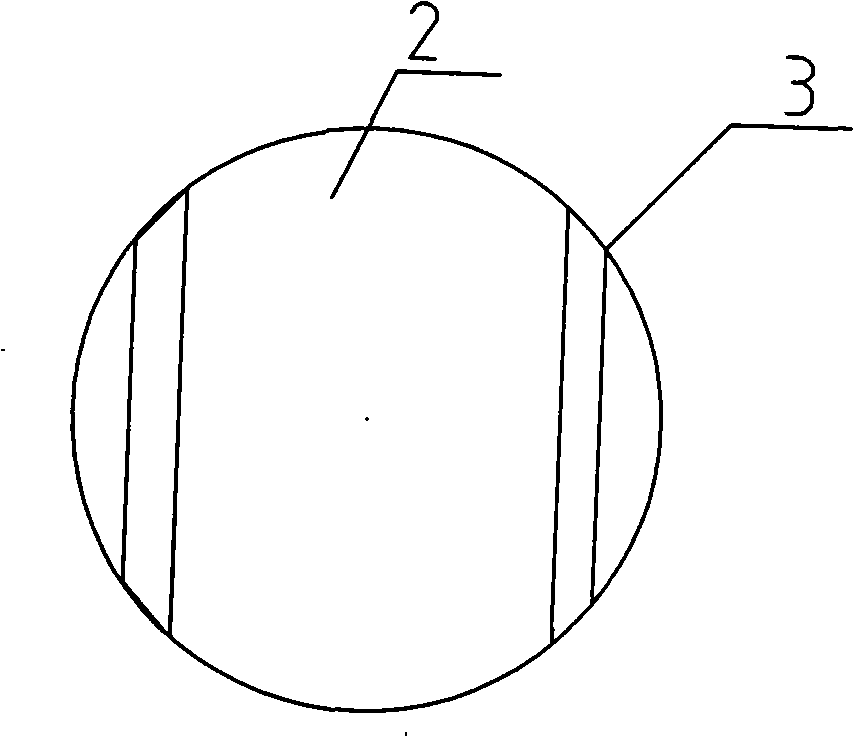

[0038] Such as Figure 4 The inner coating tube shown uses a spring retaining ring, a press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com