Preparation and application of chitosan-based nano-fiber

A nanofiber, chitosan-based technology, applied in fiber processing, fiber chemical characteristics, spinning solution preparation, etc., can solve problems such as complex process, achieve simple process, improve cell compatibility, and have broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

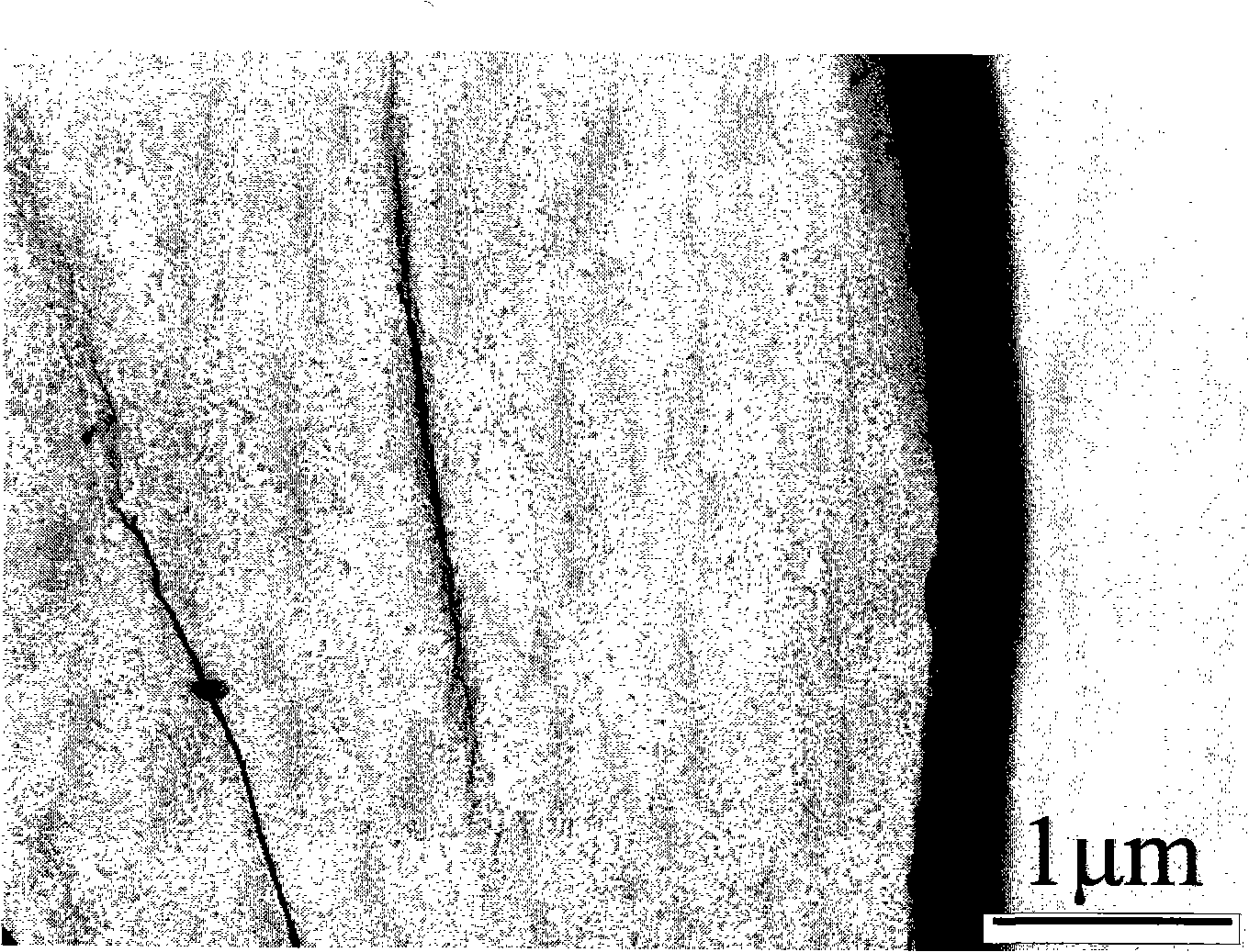

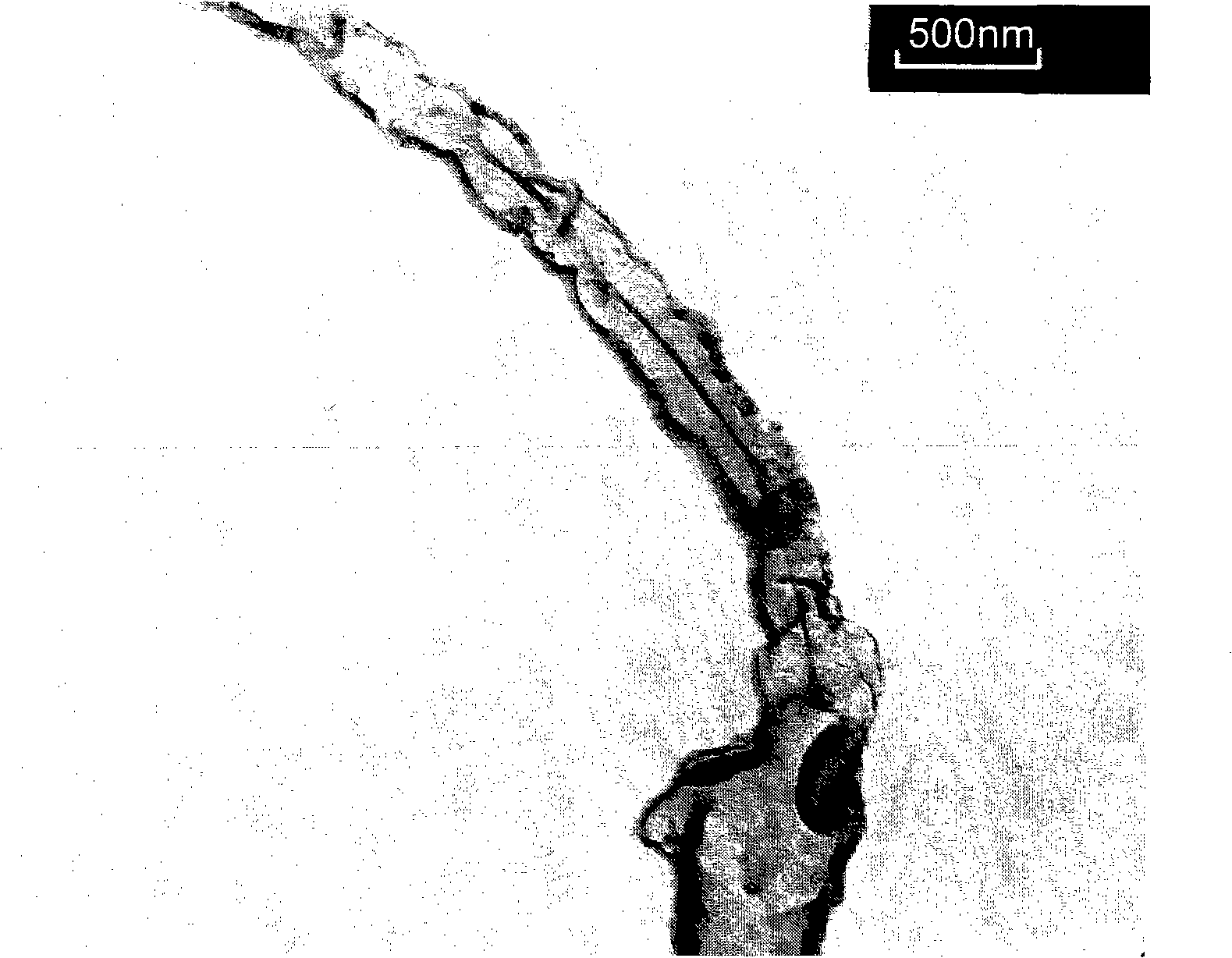

[0029] Embodiment 1 Preparation of chitosan / sodium phosphate tripolyphosphate nanofibers

[0030] The preparation method of chitosan / sodium tripolyphosphate nanofiber comprises the steps:

[0031] (1) Take by weighing 0.003 gram of chitosan (degree of deacetylation 85%) and be dissolved in the adipic acid solution of 30 milliliters 2% (g / mL), preparation concentration is the chitosan acetonitrile of 0.01% (g / mL). Diacid solution;

[0032] (2) Weigh 0.001 gram of sodium tripolyphosphate and dissolve it in 10 milliliters of deionized water to make a sodium tripolyphosphate solution with a concentration of 0.01% (g / mL);

[0033] (3) Under magnetic stirring at normal temperature, the chitosan adipic acid solution of 0.01% (g / mL) is added in the sodium tripolyphosphate solution of 0.01% (g / mL) with the speed of 1mL / min, keeps and Control the pH of the total system of the mixed solution between 3 and 6 until the dropwise addition is completed, and then stir for 1 hour;

[0034] (...

Embodiment 2

[0035] Example 2 Preparation of chitosan / sodium alginate nanofibers

[0036] The preparation method of chitosan / sodium alginate nanofiber, its step is as follows:

[0037] (1) Take by weighing 0.03 gram of chitosan (deacetylation degree 91%) and be dissolved in the adipic acid solution of 30 milliliters 2% (g / mL), preparation concentration is the chitosan acetonitrile of 0.1% (g / mL). Diacid solution;

[0038](2) Weigh 0.01 gram of sodium alginate and dissolve it in 10 milliliters of deionized water to make a sodium alginate solution with a concentration of 0.1% (g / mL);

[0039] (3) Under magnetic stirring at room temperature, add 0.1% (g / mL) chitosan adipic acid solution to 0.1% (g / mL) sodium alginate solution at a speed of 1 mL / min, keep and control The pH of the total system of the mixed solution is between 3 and 5 until the dropwise addition is completed, and then stirred for 1 hour;

[0040] (4) Centrifuge the solution obtained in the above step (3) at 20,000rpm for 30m...

Embodiment 3

[0041] Example 3 Preparation of collagen / chitosan / sodium tripolyphosphate nanofibers

[0042] (1) Take by weighing 0.03 gram of chitosan (deacetylation degree 100%) and be dissolved in the adipic acid solution of 30 milliliters 2% (g / mL), the preparation concentration is the chitosan acetonitrile of 0.1% (g / mL). Diacid solution;

[0043] (2) Take by weighing 0.003 gram of collagen and dissolve it in chitosan solution to obtain a composite solution of chitosan / collagen; Take by weighing 0.01 gram of sodium tripolyphosphate and dissolve it in 10 milliliters of deionized water to form a concentration of 0.1% (g / mL) of sodium tripolyphosphate solution;

[0044] (3) Under magnetic stirring at normal temperature, the chitosan adipic acid solution of 0.1% (g / mL) is added in the sodium tripolyphosphate solution of 0.1% (g / mL) with the speed of 1mL / min, keeps and Control the pH of the total system of the mixed solution between 3 and 5 until the dropwise addition is completed, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com