Printing electric heating membrane calandria based on vitrified enamel plate and preparation technique thereof

An electric heating film and heating body technology, which is applied in ohmic resistance heating, ohmic resistance heating parts, electric heating devices, etc., can solve the problems that hinder the popularization and application of electric heating films, low thermal conductivity of substrate materials, and high cost of electric heating film materials. The effect of strong thermal shock resistance, good safety performance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

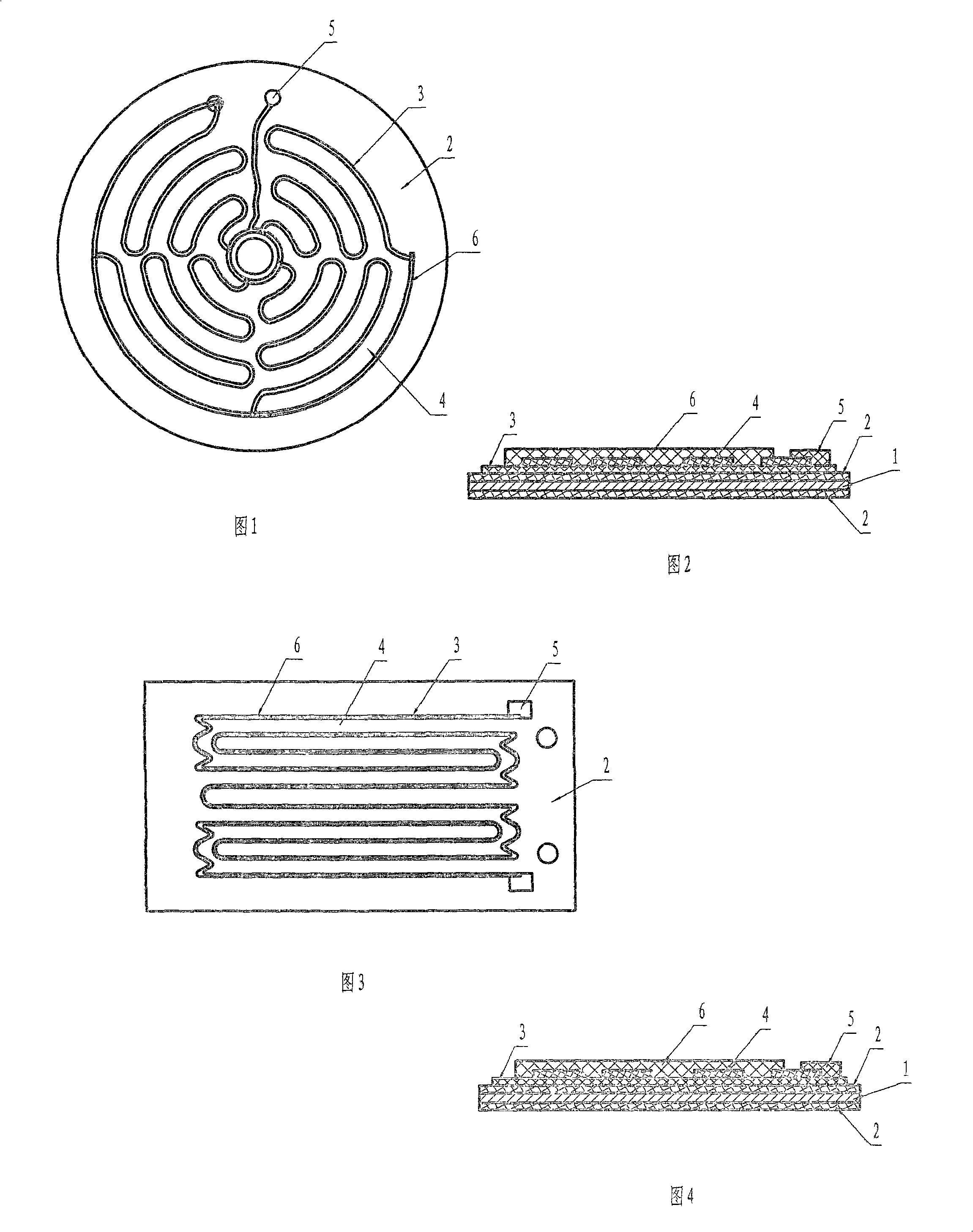

Image

Examples

Embodiment Construction

[0034] Choose 0.8mm thick enamel steel plate with a size of 550mm×310mm. After processing the process hole, spray enamel glaze on both sides, and then sinter at a temperature of 850-900°C to form an enamel plate.

[0035] Preparation of glass powder: Select 68% bismuth oxide, 14% silicon oxide, 4% boron oxide, 1% aluminum oxide and 13% zinc oxide according to the mass ratio, mix them evenly and then smelt and quench them in water. The melting temperature is 1500°C. Glass powder with an average particle size of 3 μm was obtained by ball milling.

[0036] Preparation of medium slurry: put glass powder and organic binder in a container in a mass ratio of 80%:20%, stir and disperse, then perform three-roll rolling, and then undergo vacuum defoaming treatment to obtain a slurry that can be used for screen printing media slurry.

[0037] Prepare resistance paste: put glass powder, ultra-fine silver powder, ultra-fine palladium powder and resistance binder in a mass ratio of 36%: 39...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com