Ultraviolet cured paint composition and preparation thereof

A technology of curing coatings and ultraviolet light, applied in the direction of polyurea/polyurethane coatings, coatings, instruments, etc., can solve the problems of dimensional deformation, high density of inorganic powder, temperature impact test of coating surface cracking, etc., to improve wear resistance. , the effect of ultra-high wear resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The steps of the preparation method of the ultraviolet curable coating composition used for the transparent plastic parts of the mobile phone keyboard are conventional addition steps in the field: the polyurethane acrylate accounting for 35% to 60% of the total system and the polyurethane acrylate accounting for 10% to 20% of the total system The fluorine-modified urethane acrylate and the diluent solvent accounting for 10% to 40% of the total system are mixed, stirred until fully dissolved, and the first mixture is obtained.

[0042] Add reactive diluent monomers accounting for 10-20% of the total system into the above-mentioned first mixture, stir evenly, and place it in a sealed place for 5-8 hours to form the second mixture.

[0043] Then add 0.5% to 1.5% of the well-known additives in this field in the second mixture, the leveling agent of BYK company in Germany, the wetting and dispersing agent of EFKA company in Holland, the defoamer of Cognis company in Germany and...

Embodiment 1

[0047] Prepare the UV-curable coating composition as follows:

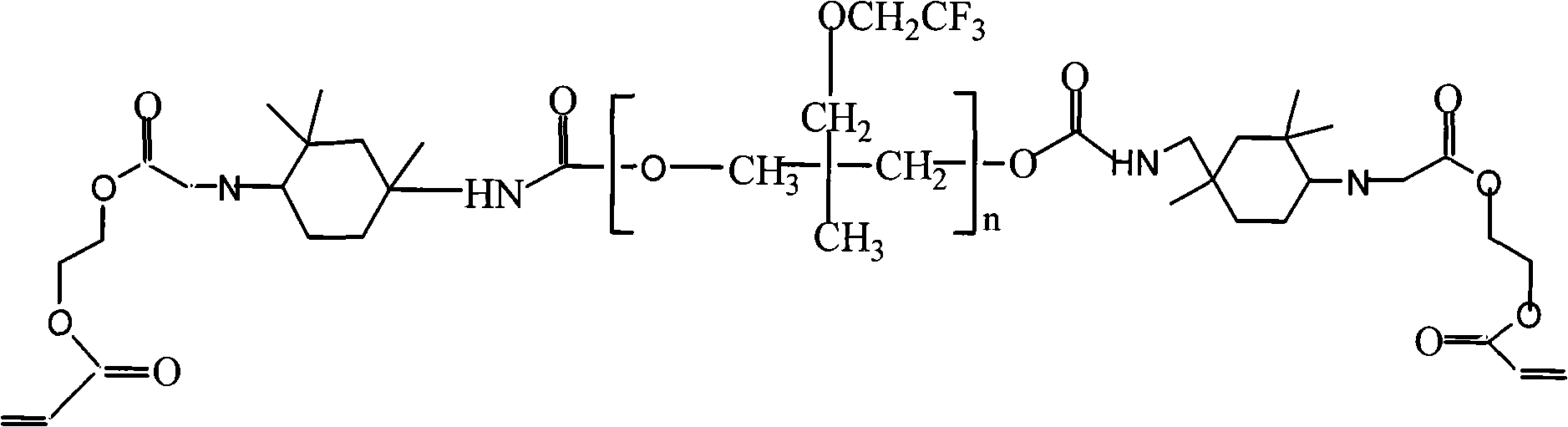

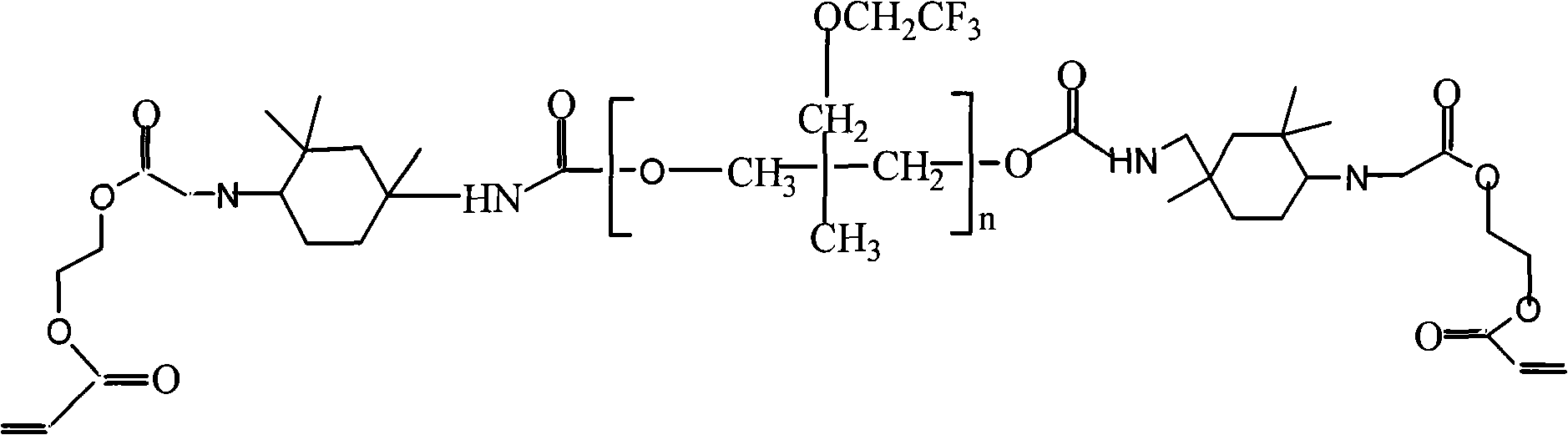

[0048] (1) Polyurethane acrylate resin (Nippon Synthetic Chemicals, UV7605B), fluorine-modified polyurethane acrylate (PF-3320, American OMNONA product), mixed with an organic solvent, dispersed evenly, to form the first mixture;

[0049] The organic solvent is: a mixture of toluene, ethyl acetate, butyl acetate, n-butanol, and cyclohexanone, wherein, toluene: ethyl acetate: butyl acetate: n-butanol: cyclohexanone=6: 2: 3: 2:1.

[0050] (2) Add reactive diluent monomer (domestic hexanediol diacrylate HDDA) into the first mixture, stir and leave it to stand to form the second mixture;

[0051] (3) Add additives to the second mixture, disperse evenly, and filter, and the filtrate is an ultraviolet light-curable coating composition. Among them, the additives are: photoinitiator Irgacure369, leveling agent F41 from Germany Cognis, wetting and dispersing agent Dispers 710;

[0052] The weight percentage of each comp...

Embodiment 2

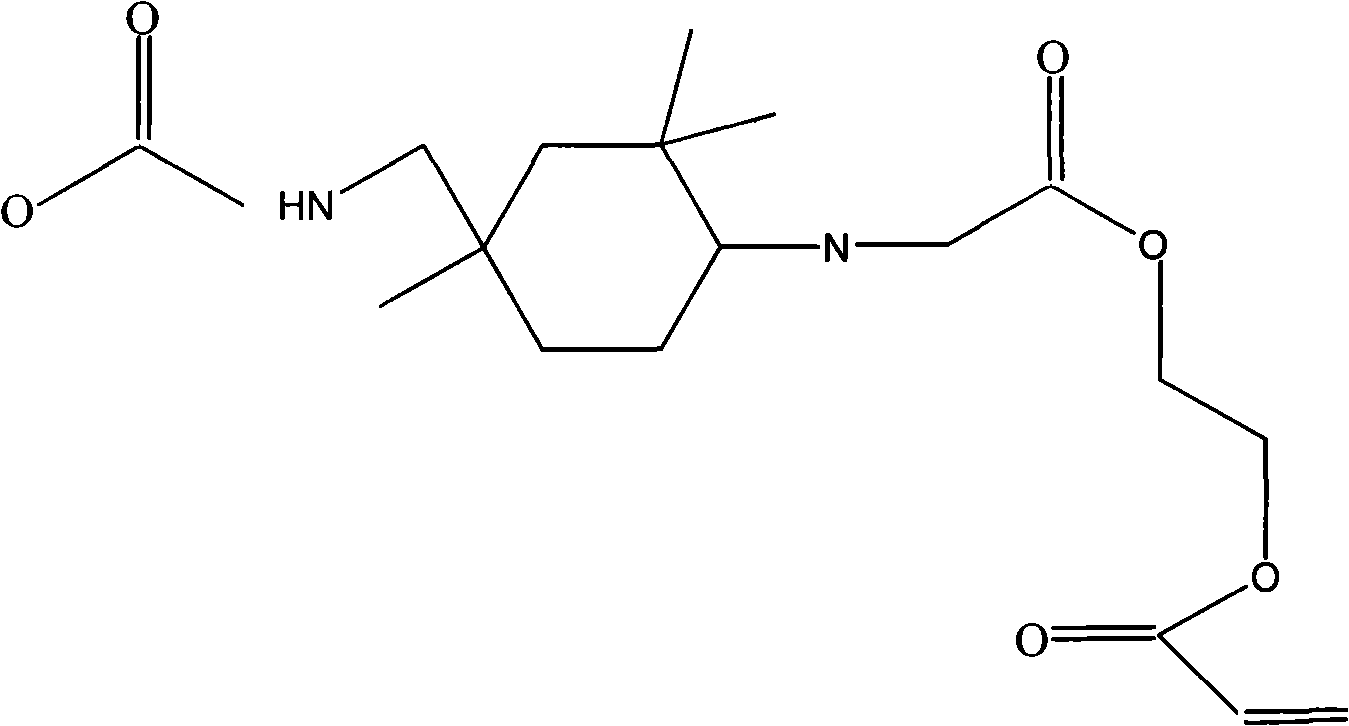

[0054] The preparation steps are the same as in Example 1. Among them, the fluorine-modified polyurethane acrylate is PF-6320 from OMNOVA Company of the United States; the reactive diluent monomer is domestic dipentaerythritol hexaacrylate DPHA; the additives are: photoinitiator Irgacure184, leveling agent DEGO410 from Germany, wetting and dispersing Agent CFC-510;

[0055] The organic solvent is: a mixture of ethyl acetate: n-butanol: cyclohexanone: ethylene glycol ether acetate, wherein, ethyl acetate: n-butanol: cyclohexanone: ethylene glycol ether acetate=3:1: 1:2.

[0056] The weight percentage of each component is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com