High ant-erosion and high performance R-Fe-B agglomeration magnetic body and its making method

A sintered magnet, high-performance technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problem of low magnetic performance, achieve high magnetic performance, reduce production costs, and save consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

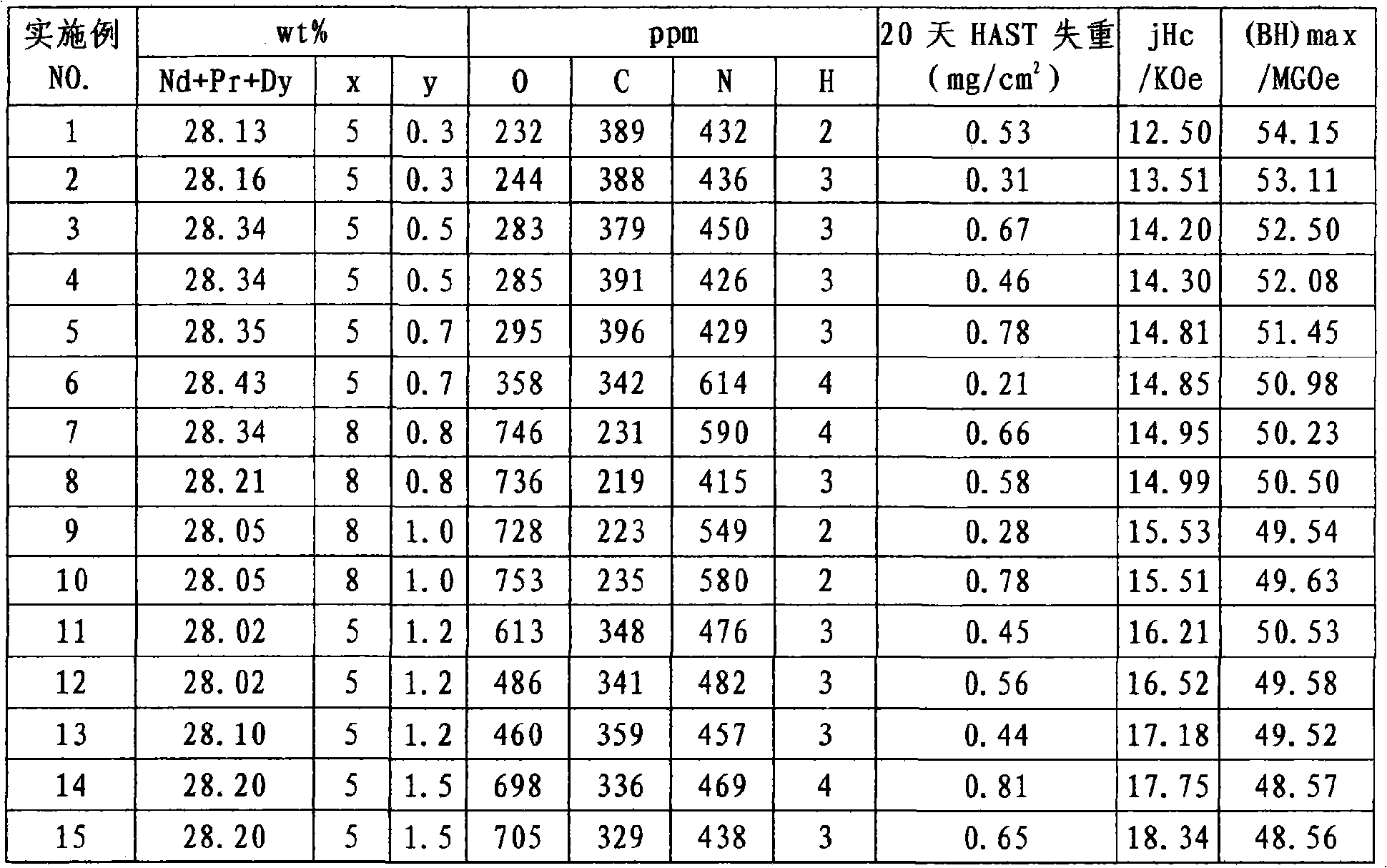

Embodiment 1~15

[0011] According to the composition of sintered magnet (weight percent) Nd 29-x-y PR x Dy y Cu 0.1 Ga 0.1 B 1 Zr 0.1 Fe 余量 (x=0~8; y=0~3), the raw materials with a purity greater than 99wt% are prepared in proportion, and melted in a 200~700Kg / time strip casting furnace (strip casting), with 5000~8000 ℃ / s cooling rate, scale casting, and finally get 0.1 ~ 0.3mm thick scales; send the scales to the hydrogen pulverization treatment furnace for hydrogen pulverization, hydrogen absorption under 90kPa hydrogen pressure for 1 to 4 hours, and then at 200 ℃ Vacuum dehydrogenation in the temperature range of ~600°C for 6-8 hours, so that the hydrogen pressure is below 10Pa, and after cooling for 6-8 hours, hydrogen crushed fragments are obtained; the crushed hydrogen fragments are placed in an oxygen-free environment with an oxygen content close to 0%. Send it to the middle grinding mill for crushing, and add oxygen element in a controlled manner during the middle grinding proce...

Embodiment 16

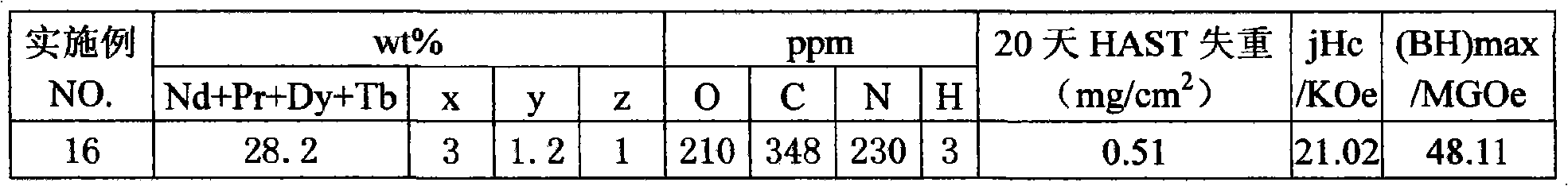

[0016] The production process is the same as above, consisting of (Nd 29-x-y-z PR x Dy y Tb z )Cr 0.1 Cu 0.15 Ga 0.1 B 1 Al 0.1 Zr 0.1 Fe 余量 , (x=0~8; y=0~3; z=0~2), adjust the values of x, y, and z to obtain magnets with high corrosion resistance, high magnetic energy product, and high coercive force, and the magnet density is 7.59 ~7.63g / cm 3 , and the measurement results are shown in Table 2.

[0017] Table 2 Composition, corrosion resistance and magnetic properties of high energy product and high coercivity magnets

[0018]

Embodiment 17~18

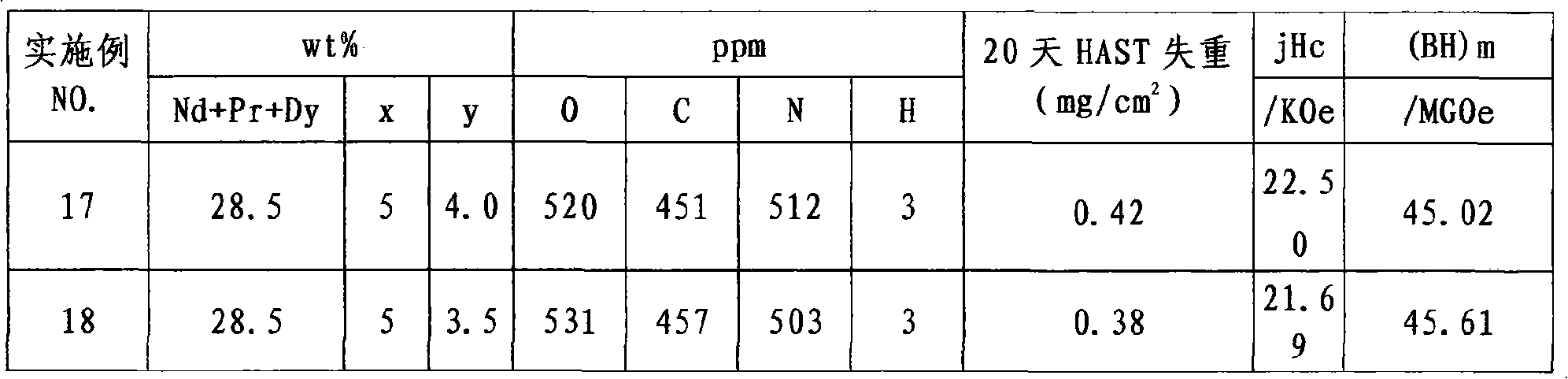

[0020] The production process is the same as above, consisting of (Nd 29.5-x-y PR x Dy y )Mo 0.4 Cu 0.15 Ti 0.1 B 1 Nb 0.2 Fe 余量 , (x=0~8; y=1~4), adjust the values of x and y to obtain magnets with high corrosion resistance, high magnetic energy product and high coercive force, and the magnet density is 7.59~7.63g / cm 3 , and the measurement results are shown in Table 3.

[0021] Table 3 Composition, corrosion resistance and magnetic properties of high energy product and high coercivity magnets

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com