Production technology for polymer lithium battery anode and cathode slice

A production process and technology of lithium batteries, applied in the direction of battery electrodes, electrode manufacturing, electrode carriers/collectors, etc., can solve the problems of continuous and poor automation of cathode and anode sheet preparation, large film thickness deviation, and reduce production technology, etc., to achieve Realization of serialization and automation, small thickness deviation, and less production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

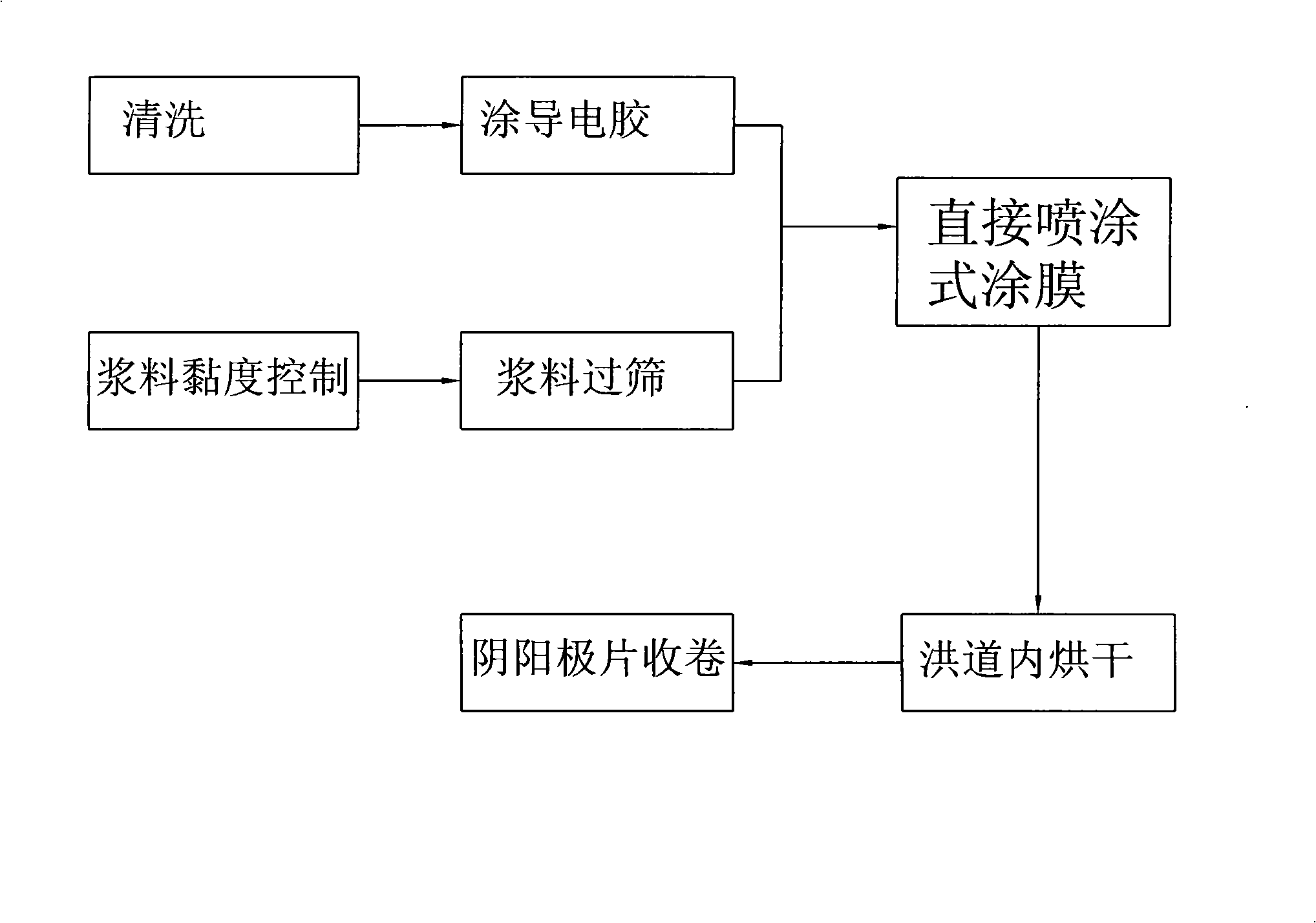

[0027] Embodiment 1: a kind of polymer lithium battery cathode and anode sheet production process (see attached figure 1 attached figure 2 ), including the following steps:

[0028] a. Cleaning: Use punched copper foil as the current collector. The porosity of the copper foil is 45%, and the aperture is 1.2mm. First remove the oil from the copper foil, and then clean it with an active agent. The active agent is controlled at a mass ratio of 1 to water. / 9, at a temperature of 40°C, wash for 70s, then pickle, the concentration of pickling is controlled at 0.3mol / L, at a temperature of 35°C, wash for 70s, then rinse with clean water and pickle at a temperature of 80°C down drying;

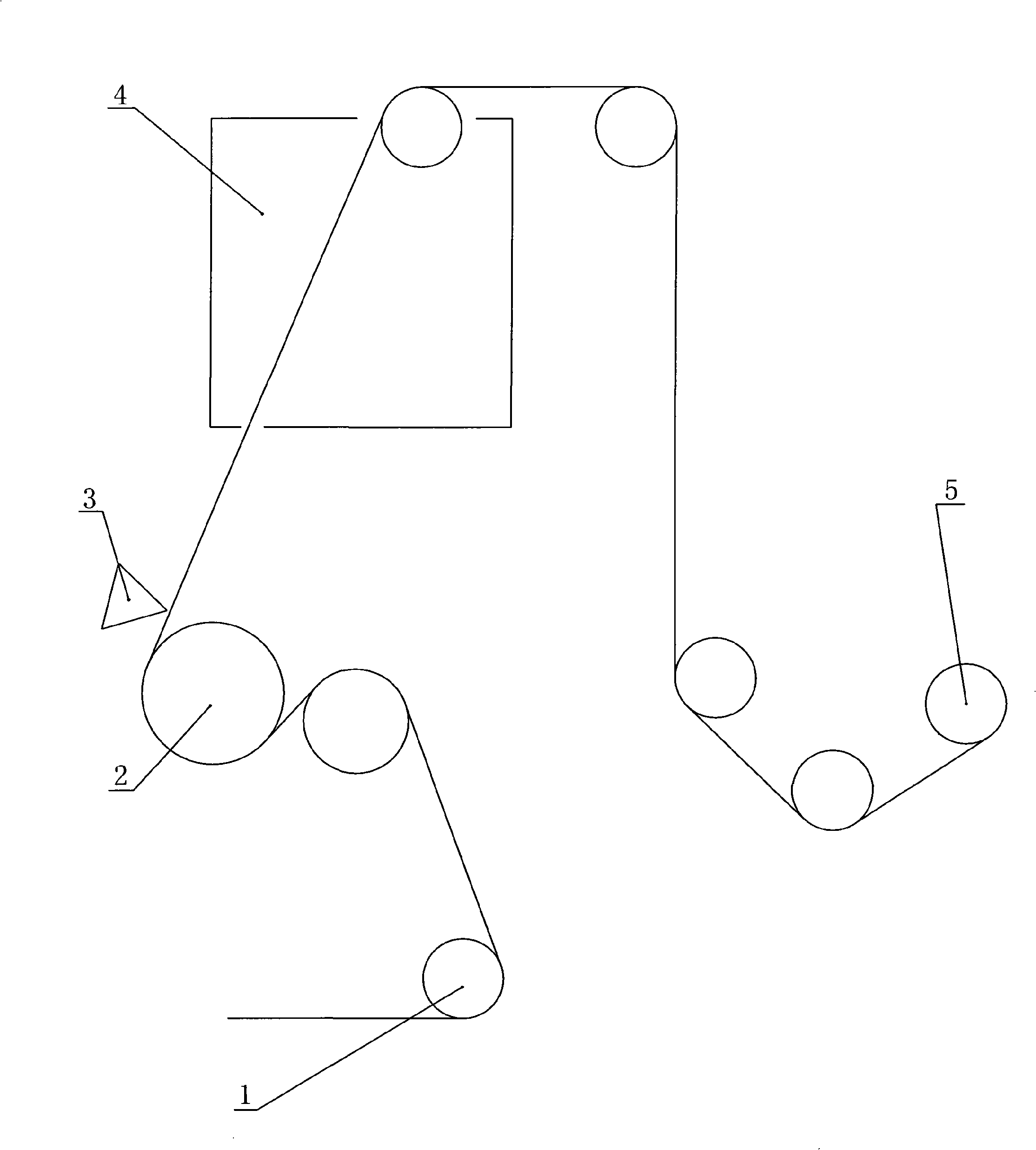

[0029] b. Coating conductive glue: apply a layer of conductive glue on the dried current collector, the thickness of the conductive glue is 8 μ, then fully dry, and place it on the unwinding roller 1;

[0030] c. Prepare cathode and anode slurry: use a rotational viscometer to select an anode and...

Embodiment 2

[0033] Embodiment 2: a kind of production process of cathode and anode sheet of polymer lithium battery, comprises the following steps:

[0034] a. Cleaning: Use punched aluminum foil as the current collector. The aluminum foil has a porosity of 38% and a pore diameter of 1.3mm. First remove the oil from the aluminum foil and clean it with an active agent. The active agent is controlled at a mass ratio of 1 / 8 to water. Wash for 80s at a temperature of 50°C, then carry out alkali washing, the concentration of alkali washing is controlled at 0.8mol / L, wash for 80s at a temperature of 40°C, then rinse with clean water and dry at a temperature of 90°C ;

[0035] b. Coating conductive glue: apply a layer of conductive glue on the dried current collector, the thickness of the conductive glue is 10μ, then fully dry, and place it on the unwinding roller 1;

[0036] c. Prepare cathode and anode slurry: use a rotational viscometer to select an anode and cathode slurry with a suitable v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com