Method for accomplishing sub-wavelength interference photolithography utilizing multiple layer metal dielectric-coating structure

A multi-layer metal, interference lithography technology, applied to the originals for optomechanical processing, photosensitive materials for optomechanical equipment, microlithography exposure equipment, etc., can solve the problem of uneven fringe visibility, short interference area, Problems such as limited transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] The present invention utilizes a multilayer metal dielectric film structure to realize a method for subwavelength interference lithography, and its specific implementation steps are as follows:

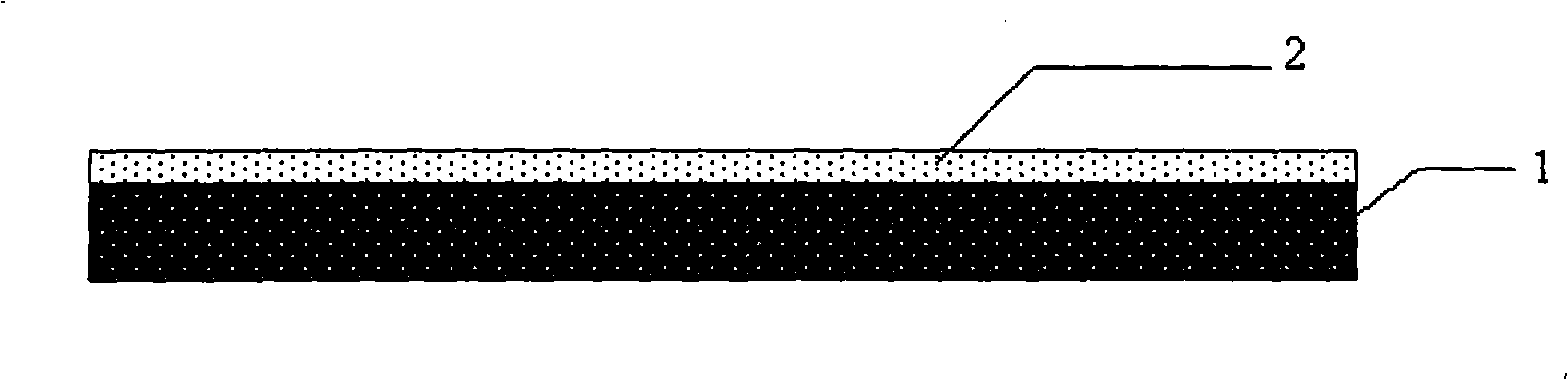

[0039] (1) Choose quartz as the base material, such as figure 1 shown;

[0040] (2) Spin-coat a layer of resist AZ3100 on the surface of the substrate with a thickness of 100nm, such as figure 2 shown;

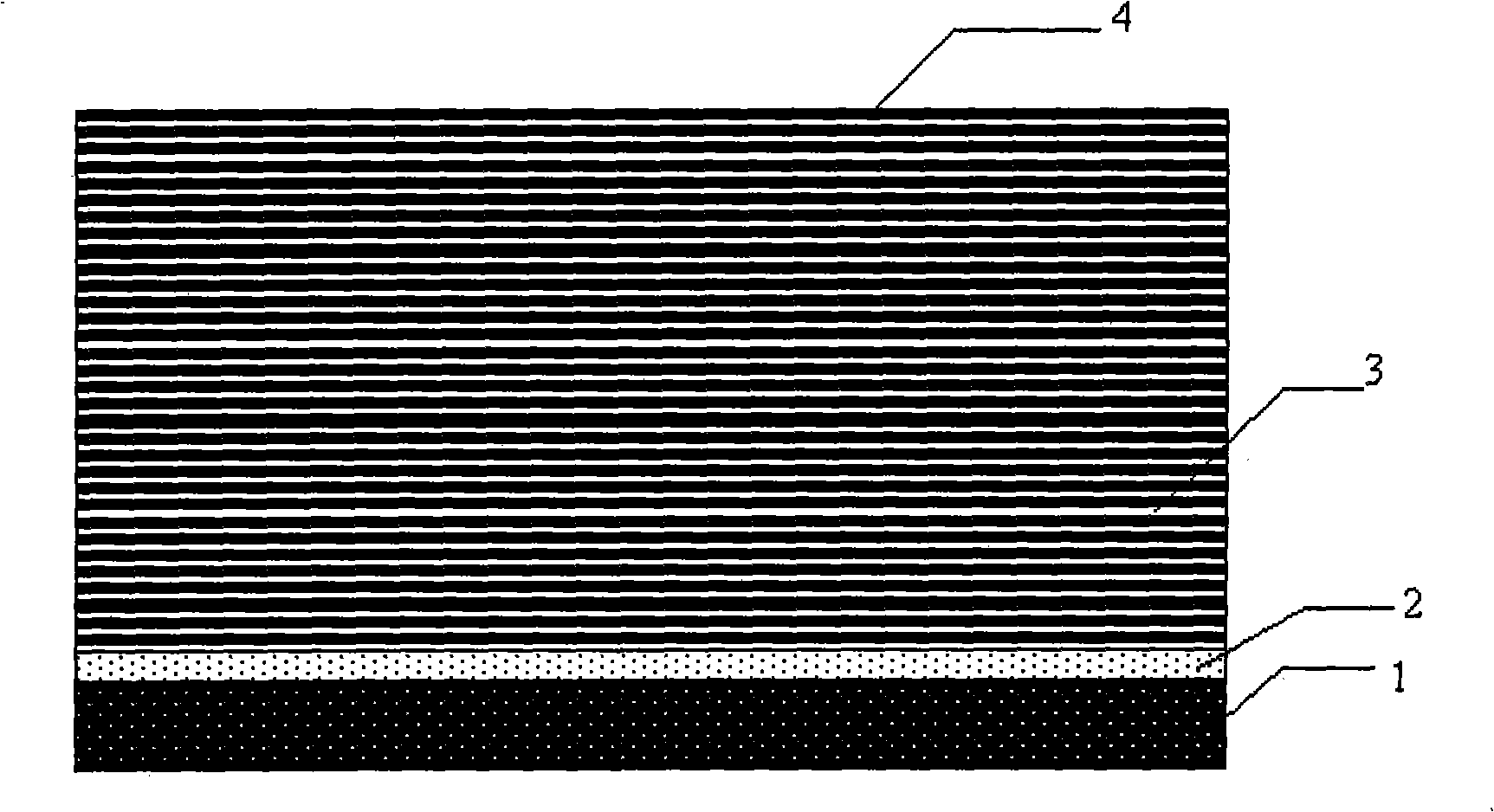

[0041] (3) Metal silver film and magnesium fluoride film are vapor-deposited alternately on the resist surface, the thickness of silver layer is 20nm, the thickness of magnesium fluoride is 30nm, wherein silver layer and magnesium fluoride layer are respectively 35 layers, obtain structure Such as image 3 shown;

[0042] (4) Design and fabricate the mask structure. It is proposed to obtain photolithography lines with a line width of 32n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com