Weight bearing tissue engineering bone porous pure magnesium bracket and bracket imitation human bone material surface coatings

A tissue engineering bone and surface coating technology, applied in the field of biomedical engineering materials, can solve the problems of bone defects that cannot be applied to the weight-bearing parts of the limbs, lack of mechanical strength, etc., and achieve strong designability, good adhesion or affinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

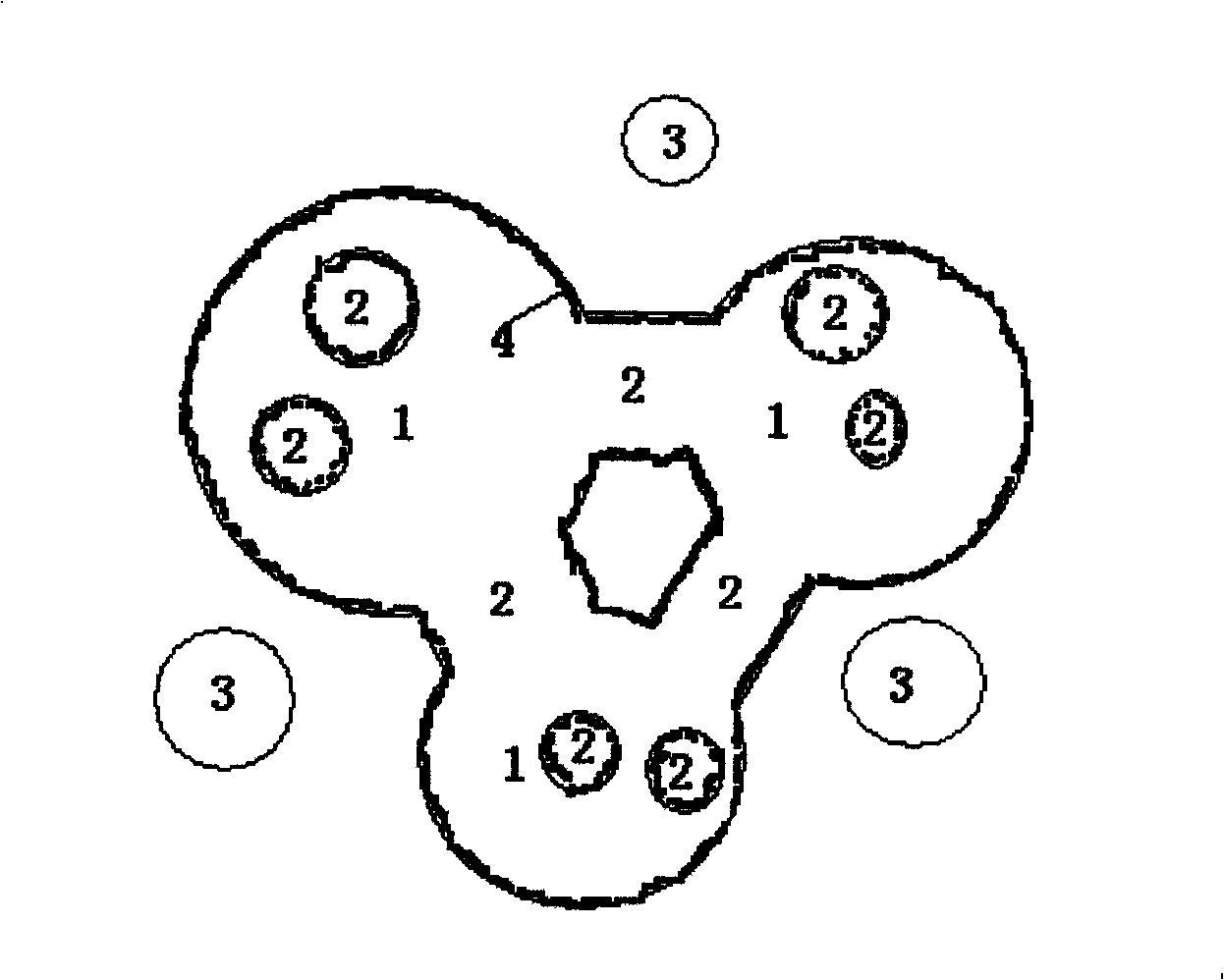

[0030] like figure 1 , 2 Shown: the porous pure magnesium scaffold for load-bearing tissue engineering bone of the present invention, the porous pure magnesium scaffold is composed of magnesium powder with a particle size of ≤150 μm and a purity of ≥99.9% and a granular organic powder with a particle size of 100-500 μm and a purity of ≥99.0%. Pore agent, processed by powder metallurgy to make cylinders or discs with different diameters (D) and heights (H), and randomly distribute main holes (1), connected holes (2) and Blind holes (3), the main holes are connected with each other to form connected holes, and the blind holes are closed and not connected. The porous pure magnesium support is powder metallurgy, which is to mix the magnesium powder and the granular organic pore-forming agent evenly, pour it into the metal mold, and compress the prefabricated body under the pressure of 100MPa along the axial direction of the porous pure magnesium support; In an argon atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com