Method for preparing carbon nano-tube/nano-nickel composite film

A technology of carbon nanotubes and composite films, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of rough coating surface, limited carbon nanotube reinforcement, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

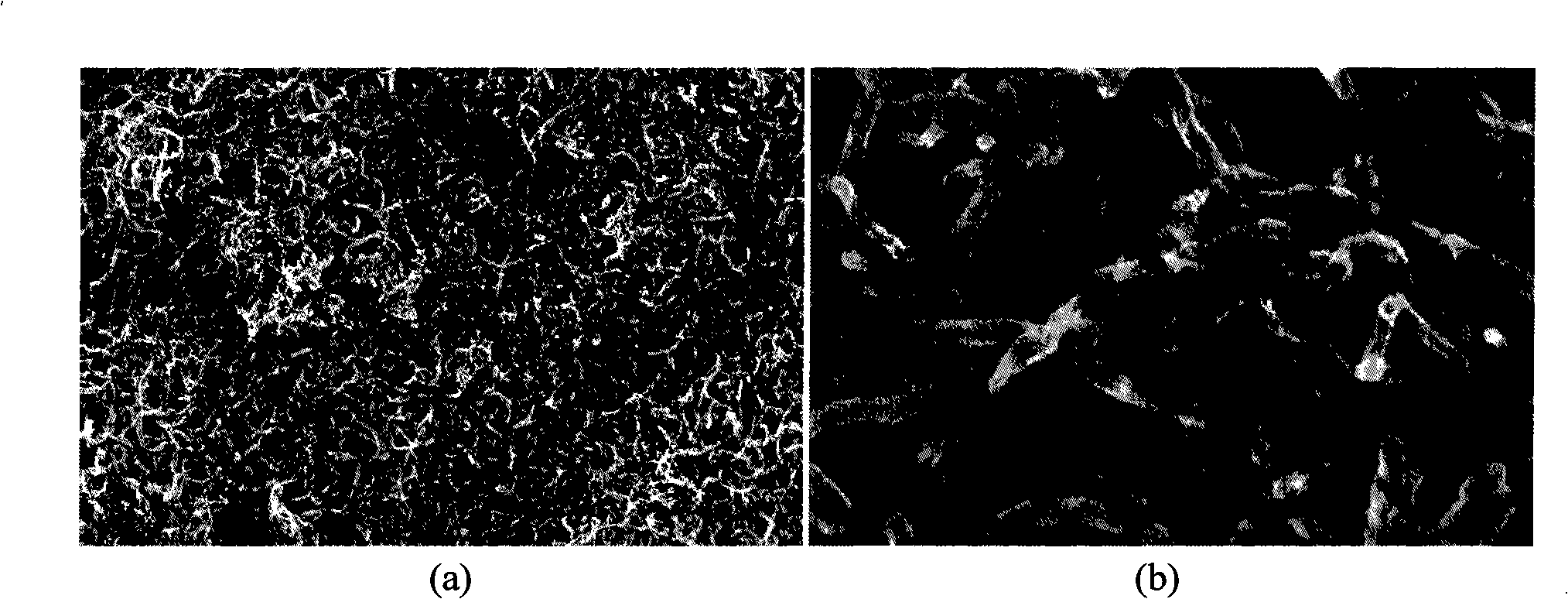

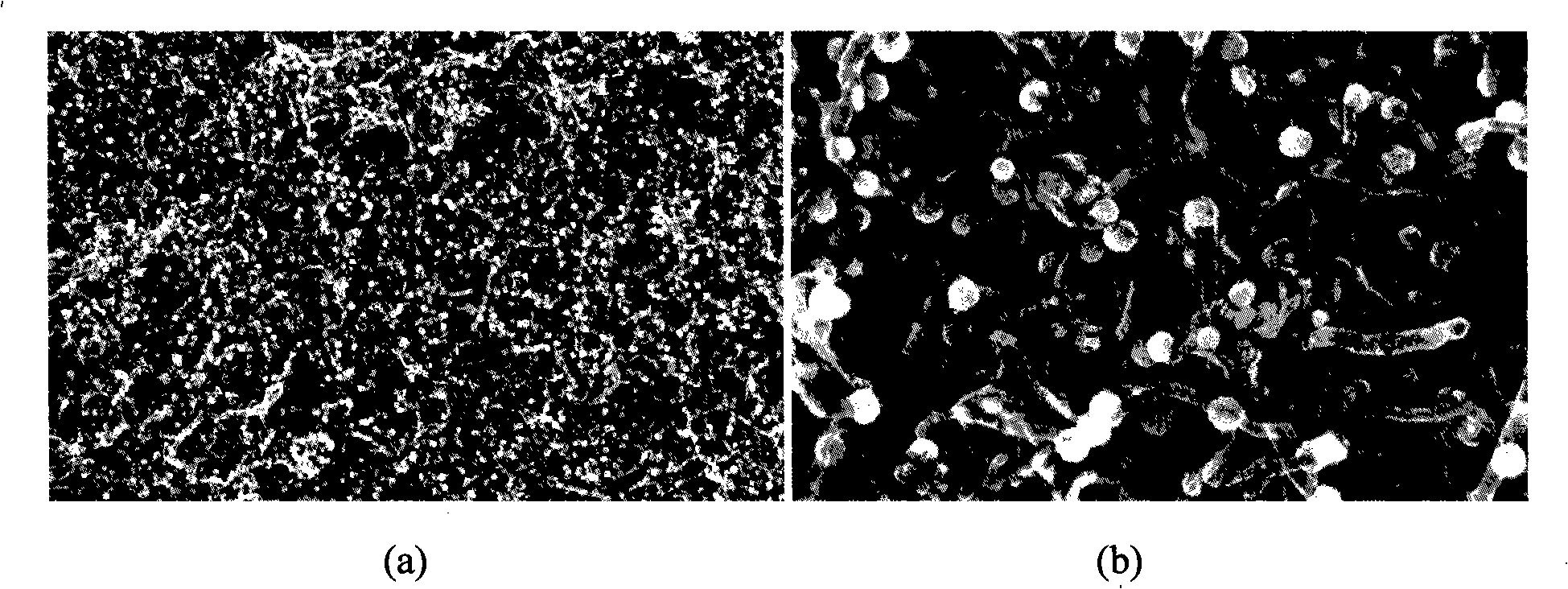

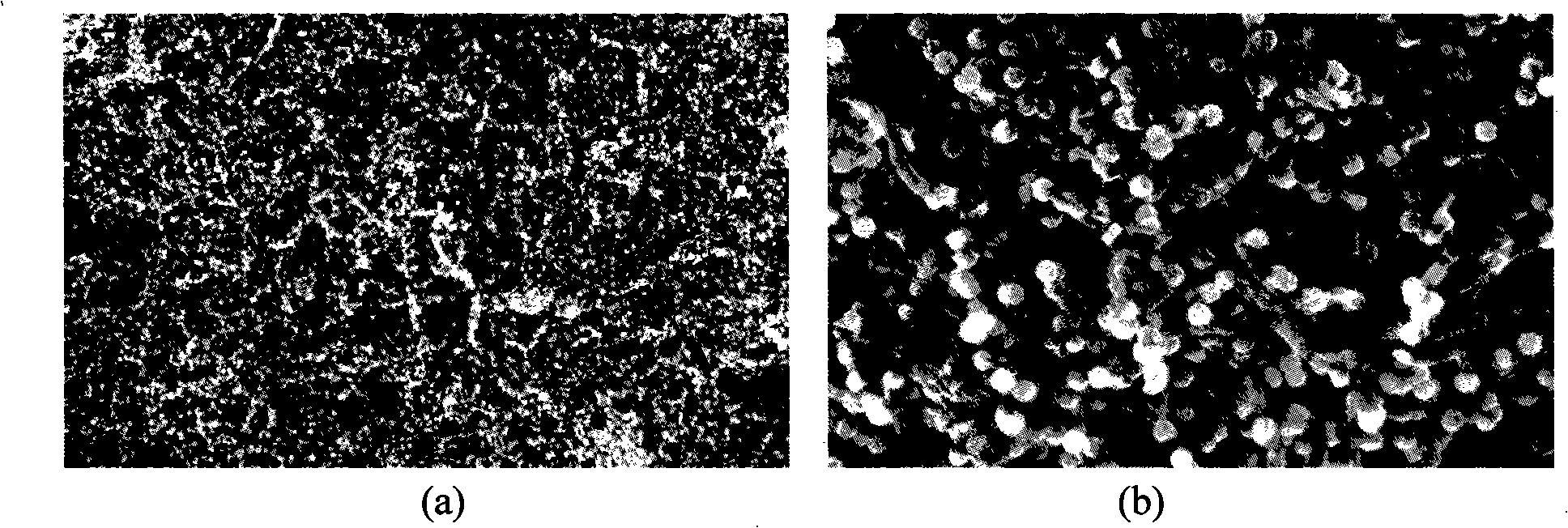

Image

Examples

Embodiment 1

[0029] 1. Substrate pretreatment: (1) Surface polishing: Polish the aluminum foil (thickness 100 μm) with 2#, 4#, 6#, 8# metallographic sandpaper in sequence until the surface is uniform and bright. (2) Degreasing and degreasing: Put the polished aluminum foil into a beaker filled with distilled water, and after ultrasonic cleaning for 5 minutes, put it in acetone for 3 to 5 minutes to remove surface oil, take it out and wash it with twice distilled water, and place Dry in an oven at 120°C for use.

[0030] 2. Preparation of electrophoretic suspension: Weigh about 0.01g of carbon nanotubes into a 150ml beaker, measure 50ml of acetylacetone, cover with a film, and use ultrasonic vibration for 1 hour before use.

[0031] 3. Electrophoretic deposition: before deposition, stir the suspension and ultrasonically for 25 minutes, insert a cylindrical stainless steel electrode (as the anode) into the middle of the suspension, and insert the pretreated and dried aluminum foil (as the ca...

Embodiment 2

[0036] 1. Substrate pretreatment: (1) Surface polishing: Polish the titanium foil (thickness 100 μm) with 2#, 4#, 6#, 8# metallographic sandpaper in sequence until the surface is uniform and bright. (2) Degreasing and degreasing: Put the polished aluminum foil into a beaker filled with distilled water, and after ultrasonic cleaning for 5 minutes, put it in acetone for 3 to 5 minutes to remove surface oil, take it out and wash it with twice distilled water, and place Dry in an oven at 120°C for use.

[0037] 2. Preparation of electrophoretic suspension: prepare electrophoretic liquid according to Example 1.

[0038] 3. Electrophoretic deposition: before deposition, stir the suspension and sonicate for 25 minutes, insert a cylindrical stainless steel electrode (as an anode) into the middle of the suspension, insert a pretreated and dried stainless steel foil (as a cathode) into the suspension, and place In the middle, adjust the DC power supply voltage to 60V, adjust the curren...

Embodiment 3

[0043] 1. Substrate pretreatment: (1) Surface polishing: Polish the stainless steel foil (thickness 100-200μm) with 2#, 4#, 6#, 8# metallographic sandpaper in sequence until the surface is uniform and bright. (2) Degreasing and degreasing: Put the polished titanium foil into a beaker filled with distilled water, after ultrasonic cleaning for 5 minutes, put it in acetone for 3 to 5 minutes, remove the surface oil, take it out and wash it with twice distilled water, Dry in an oven at 120°C for later use.

[0044] 2. Preparation of electrophoretic suspension: Weigh about 0.02g of carbon nanotubes into a 150ml beaker, measure 50ml of acetylacetone, cover with a film, and use ultrasonic vibration for 1 hour before use.

[0045] 3. Electrophoretic deposition: before deposition, stir the suspension and sonicate for 25 minutes, insert a cylindrical stainless steel electrode (as an anode) into the middle of the suspension, insert a pretreated and dried stainless steel foil (as a cathod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com