Preparation method of wet-curing reaction type polyurethane hot melt adhesives for shoes

A polyurethane hot-melt adhesive and moisture-curing technology, which is applied in the field of polyurethane adhesives, can solve the problems of poor water resistance, inferior to ester bonds, and low bonding strength, and achieve good durability, strong hygroscopicity, and high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

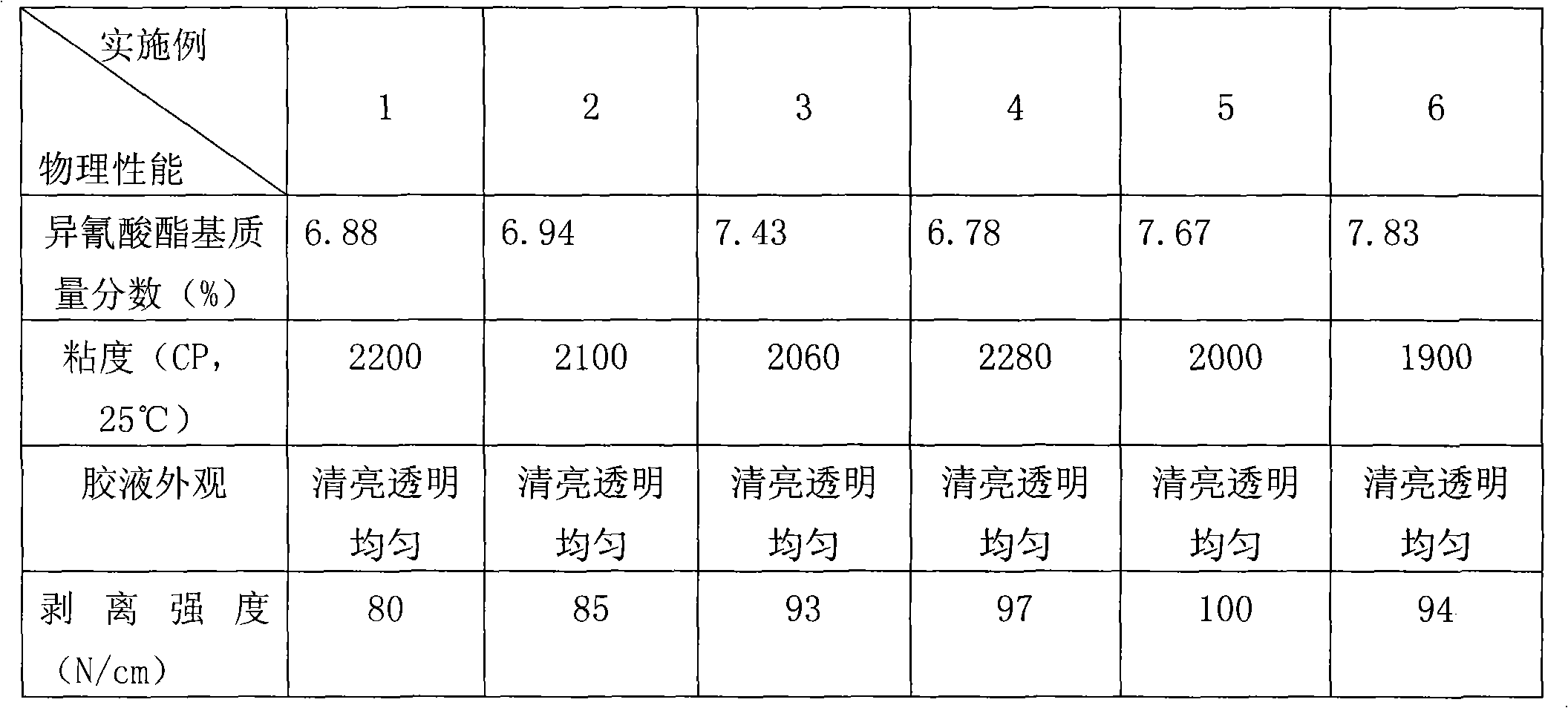

Examples

Embodiment 1

[0024] A preparation method for moisture-curing reactive polyurethane hot-melt adhesive for shoes, which comprises the following steps:

[0025] 1) Selection of raw materials: The raw materials are weighed according to the following parts by weight: 65 parts of hydroxyl-terminated liquid rubber, 15 parts of polyether diol, 13 parts of toluene diisocyanate, 4 parts of trimethylolpropane (crosslinking agent), viscosity-increasing 12 parts of resin, 0.2 part of catalyst;

[0026] Described hydroxyl-terminated liquid rubber is hydroxyl-terminated polybutadiene; described polyether glycol is polyether glycol (N210) (Shanghai Shengyi Chemical Trade Co., Ltd.); described toluene diisocyanate is 2 , 4-toluene diisocyanate; Described tackifying resin is terpene resin; Described catalyst is dibutyltin dilaurate;

[0027] 2) Add hydroxyl-terminated polybutadiene and polyether diol (N210) into a four-necked flask equipped with an electric stirring device, a heating device, a thermometer ...

Embodiment 2

[0032] The preparation method is the same as in Example 1, only the polyether diol (N210) is replaced with polytetrahydrofuran diol. The test results of its basic physical properties are shown in Table 1.

Embodiment 3

[0034] A preparation method for moisture-curing reactive polyurethane hot-melt adhesive for shoes, which comprises the following steps:

[0035] 1) Selection of raw materials: The raw materials are weighed according to the following parts by weight: 60 parts of hydroxyl-terminated liquid rubber, 15 parts of polyether diol, 13 parts of toluene diisocyanate, 4 parts of trimethylolpropane (crosslinking agent), viscosity increasing 12 parts of resin, 0.2 part of catalyst;

[0036] Described hydroxyl-terminated liquid rubber is hydroxyl-terminated polybutadiene-acrylonitrile; described polyether glycol is polyether glycol (N210) (Shanghai Shengyi Chemical Trading Co., Ltd); Isocyanate is 2,6-toluene diisocyanate; Described tackifying resin is coumarone resin; Described catalyst is tertiary amine (triethanolamine);

[0037] 2) Add hydroxyl-terminated polybutadiene-acrylonitrile and polyether diol (N210) into a four-necked flask equipped with electric stirring device, heating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com