Consumer waste innocent treatment comprehensive utilization technique

A technology for harmless treatment and domestic waste, applied in the direction of bio-organic part treatment, application, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

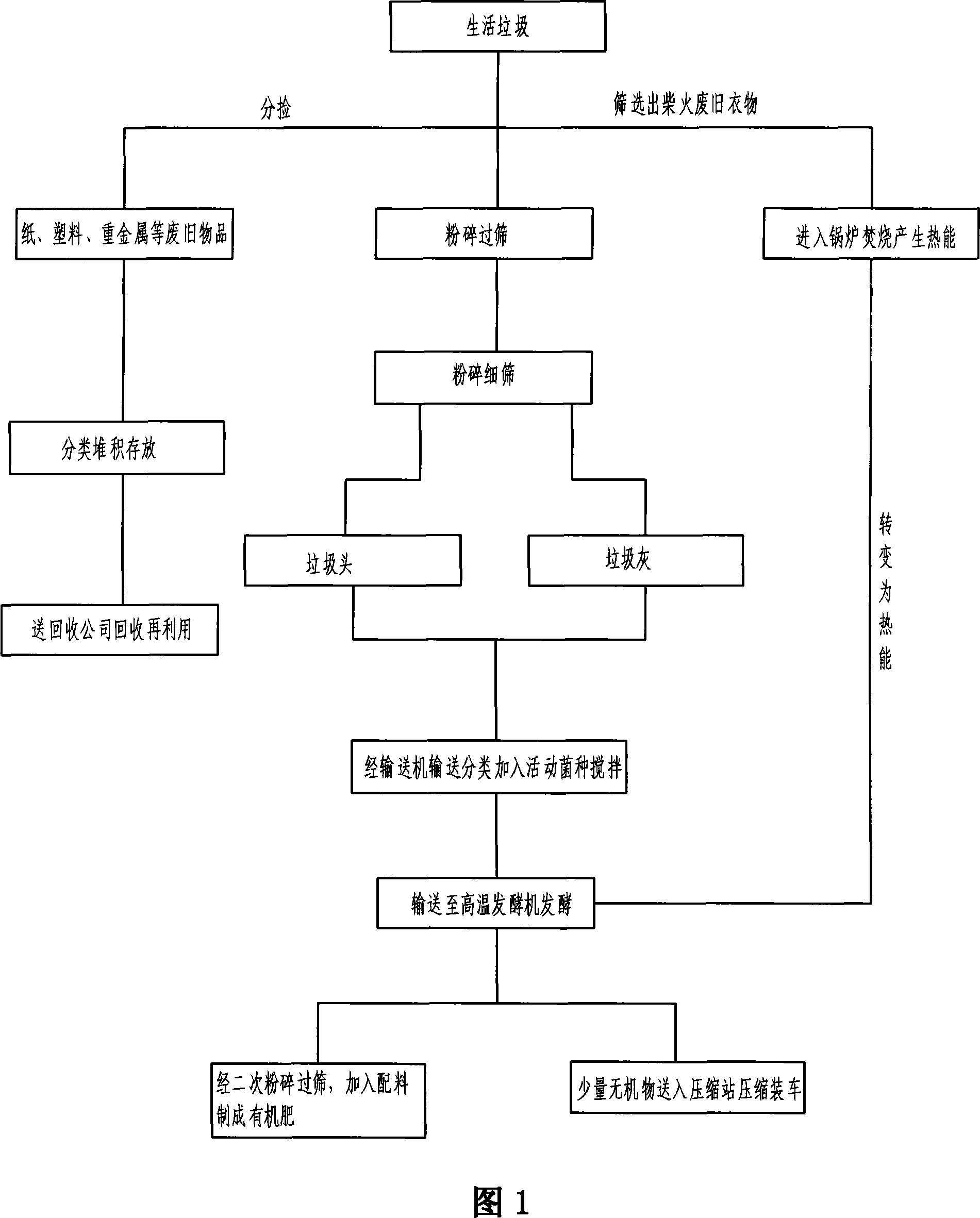

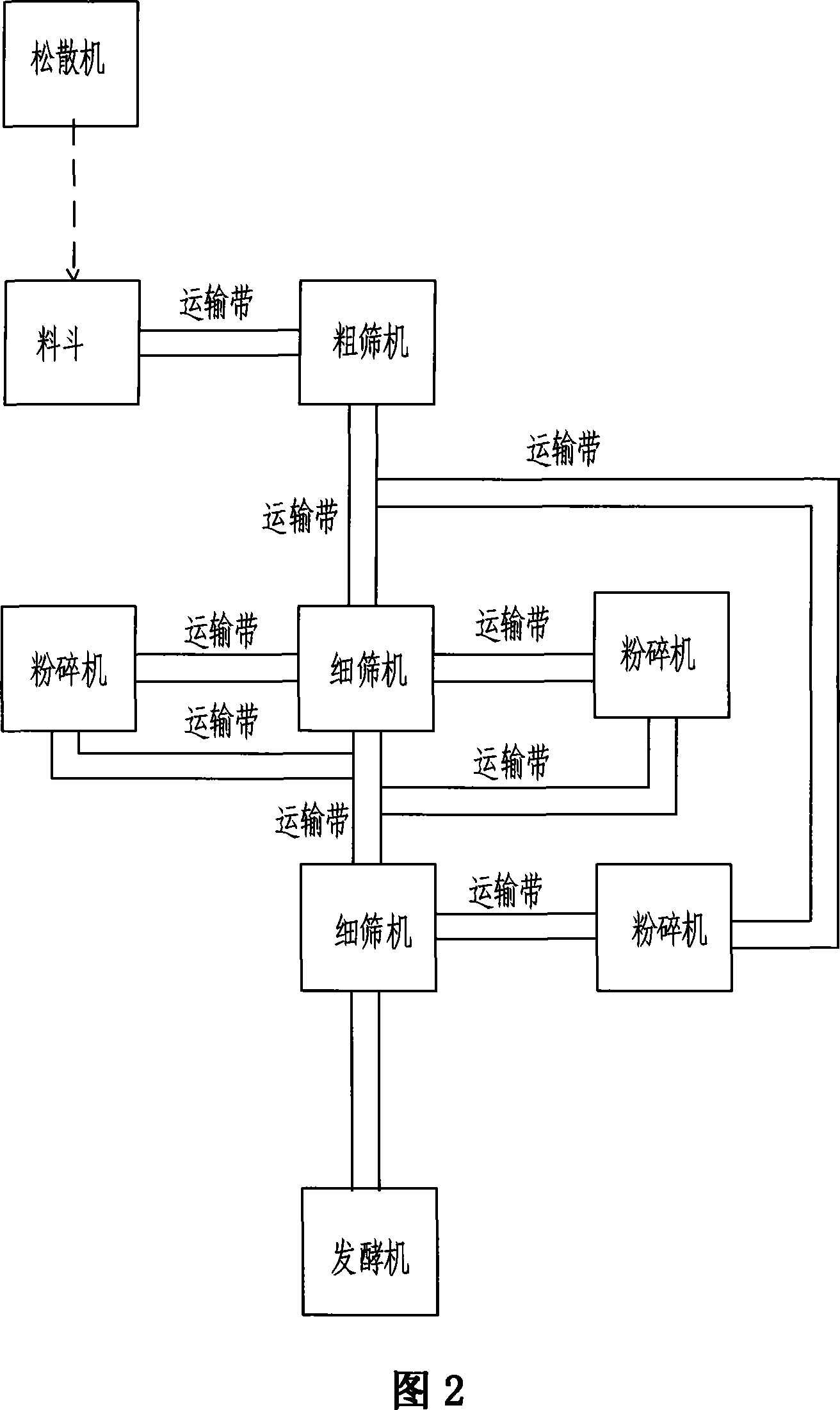

[0010] Example 1: First, by sorting and screening raw domestic waste, recyclable waste items including paper, plastic and heavy metals are sorted out for recycling, and combustibles including plants and waste clothes are sorted out and sent to burners for combustion; Then, the remaining garbage is crushed and sieved more than once or twice, and then the active bacteria are added into the classification and stirred evenly, and then sent to the high-temperature fermentation machine to be fermented to make organic fertilizer nutrient soil. The present invention can utilize the heat energy generated by burning combustibles such as plants, firewood and waste clothes in the burner to heat the high temperature fermentation machine, so as to fully utilize the resources and dispose of the waste. The high temperature fermentation machine is best to use a closed fermentation tank to avoid pollution to the surrounding air. The active bacteria can be high temperature fermentation bacteria,...

Embodiment 2

[0014] Example 2, first put the raw material domestic waste including organic waste feces and residues into the fermentation tank. If the moisture is relatively high, such as when the moisture content is close to but not more than 40%, sepiolite clay mineral powder needs to be added to adjust the humidity. , heating up to 80-95 ℃, such as controlling the temperature at 90 ℃, sterilizing for three hours, then cooling to 60-75 ℃, such as about 70 ℃, adding HB strains for aerobic fermentation for 18-32 hours, such as 24 hours The purpose of complete fermentation can be achieved, the fermentation process is ended, and the material can be bagged after cooling. See Figures 1 and 2. The rest are the same as in Example 1.

Embodiment 3

[0015] Example 3, first put raw domestic waste including organic waste feces and residues into the fermentation tank, add plant straw powder or sawdust, heat up to 80-95 ° C, sterilize for three hours, and then cool down to 6-75 ° C , adding HB strains to carry out aerobic fermentation for 18-32 hours, and the material can be bagged after cooling. See Figures 1 and 2. The rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com