Dissepiment strainer plate inlet orifice clamping head

A membrane filter plate and feed port technology, which is applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of ring chuck expansion, fluid extravasation or leakage, affecting the working efficiency of the membrane filter plate, etc. , to achieve the effect of novel structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

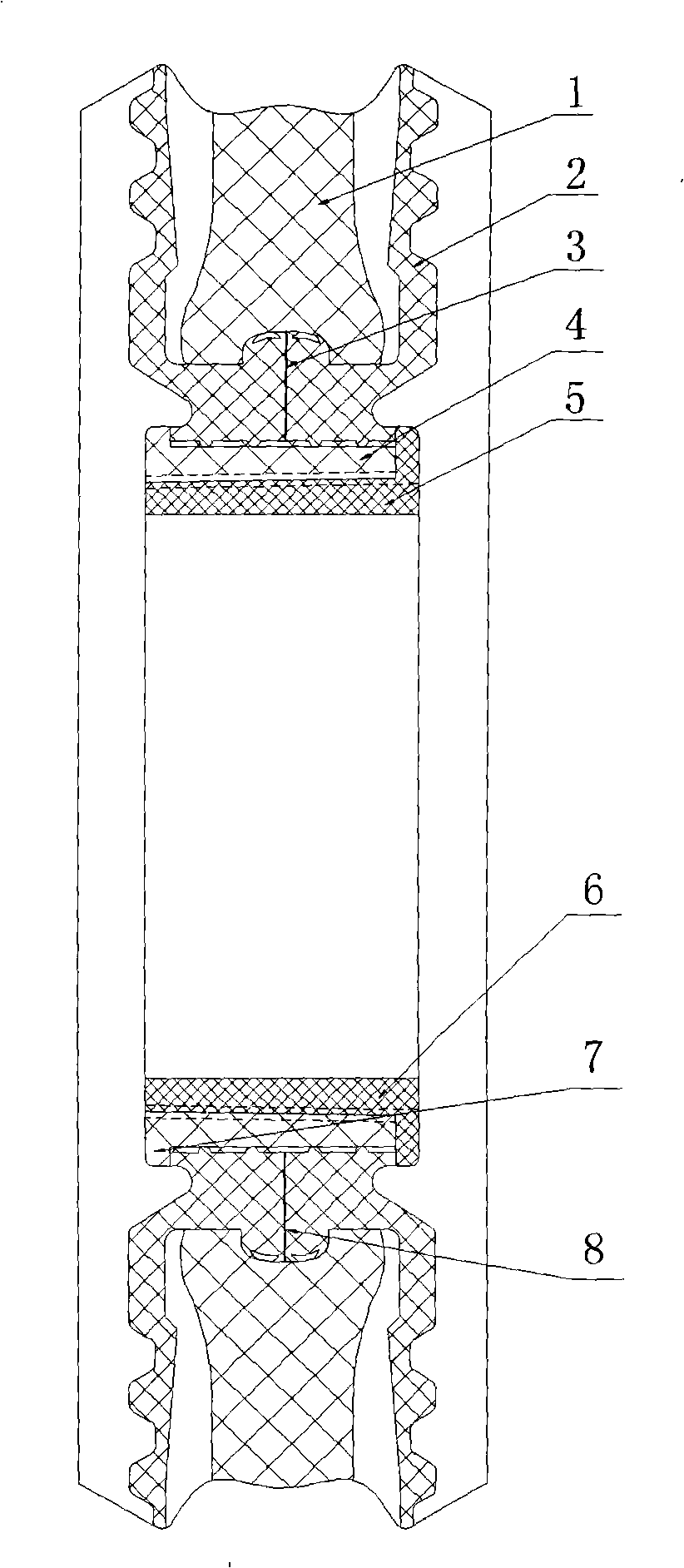

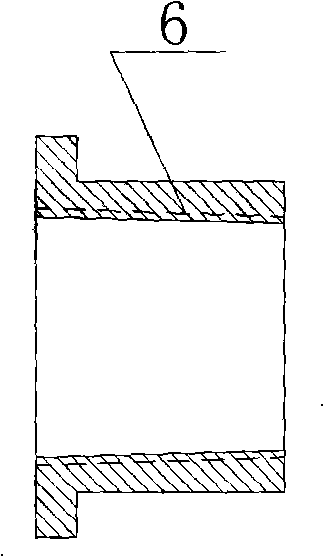

[0012] Embodiment 1: with reference to attached Figure 2-4 . Diaphragm filter plate feed inlet collet, it comprises hollow collet 6, flange collet 7, and hollow collet 6 wall has expansion wire groove 9 (this wire groove is through groove) and adopts mold injection molding. The flange chuck 7 is molded by injection molding and is screwed into the hollow chuck 6 to expand the wall of the hollow chuck 6. The inner wall of the hollow chuck 6 has a taper, and the outer wall of the flange chuck 7 has a taper. The taper matches the taper in the inner wall of the hollow collet 6, and the hollow collet 6 and the flange collet 7 are made of plastic or polymer material or metal material.

Embodiment 2

[0013] Embodiment 2: with reference to attached figure 1 . On the basis of Example 1, the diaphragm filter plate composed of the chuck of the inlet of the membrane filter plate has an annular groove on the wall of the inlet of the plate core and is injection molded or molded by injection molding or compression molding. The feeding port of the diaphragm 2 has a flanging structure and is made by the prior art, so it will not be described here. The back ring of the flange of the diaphragm feeding port is provided with a boss 4, the bottom of the boss 3 has one or two or more laps of lip 3, and the diaphragm portion adjacent to one or two or more laps of lip 3 has a concave The grooves form an open damping chamber 8 with one or two or more laps of the lip 3 respectively. The open damping chamber 8 and the groove in the plate core 1 are sealed and squeezed together, and the mouth surface of the feeding port of the diaphragm 2 is Concave-convex point distribution surface 5, expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com