Continuous multiple surfaces two-phase structure constant temperature vacuum dewatering process and device and applications thereof

A vacuum dehydration and multi-surface technology, applied in vacuum distillation, separation methods, chemical instruments and methods, etc., can solve the problems of poor heat transfer, mass transfer effect, wide water content distribution, expensive equipment cost, etc., and achieve good heating effect , large heating surface, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

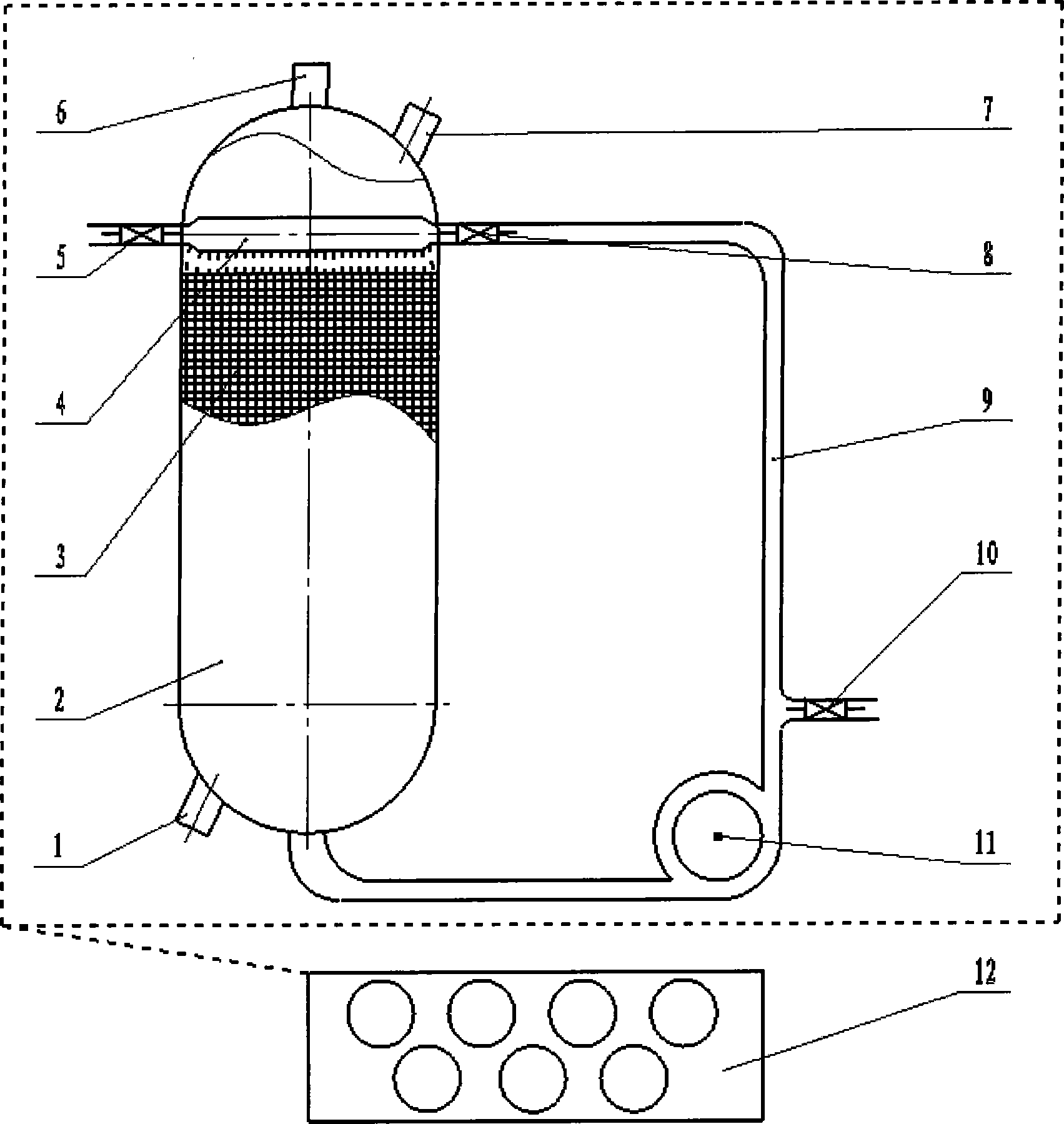

[0029] As shown in Figure 1, this continuous multi-surface two-phase structure constant temperature vacuum dehydration device includes a heat preservation tank 2, a vacuum system, a circulation pump 11, and a control system 12. The heat preservation tank 2 is provided with an internal heating tube bundle 3 and a cutting spray head 4 , the cutting sprinkler head 4 is located above the inner heating tube bundle 3; the cutting sprinkler head 4 is connected with the feed control valve 5 of the heat preservation tank 2, and the circulation control valve 8 of the outlet bypass of the circulation pump 11; the inlet of the circulation pump 11 is connected with the insulation The bottom of the tank 2 is connected, and the outlet of the circulation pump 11 is provided with a discharge control valve 10; the vacuum system is connected with the vacuum port 6 on the top of the insulation tank 2; the control system 12 is connected with the feed control valve 5, the circulation control valve 8,...

Embodiment 2

[0035] In the prepolymer synthesis process of cast polyurethane (CPU), the water content index of the raw material oligomer polyol is required to be less than 5 / 10,000, and the lower the water content index, the narrower the distribution, the more conducive to the synthesis of high quality prepolymer. Using the above-mentioned continuous multi-surface two-phase structure constant temperature vacuum dehydration device as shown in Figure 1 to carry out continuous multi-surface two-phase structure constant temperature vacuum dehydration of oligomer polyols, including the following steps:

[0036] (1) Circulate the heat medium into the inner cavity of the inner heating tube bundle or start the electromagnetic heater, and quickly raise the temperature of the closed multi-surface constant temperature material cavity formed by the inner surface of the insulation tank and the outer surface of the inner heating tube bundle to 110±2°C;

[0037] (2) Start the vacuum system to take away t...

Embodiment 3

[0042] In the crude oil industry, after the first separation of free water in the high-water content crude oil produced by sedimentation and separation equipment, if the water content is still higher than 10%, the electric dehydration equipment is directly used to break the emulsion and dehydrate, which is easy to short circuit and damage the electrodes. At this time, the above-mentioned continuous multi-surface two-phase structure constant temperature vacuum dehydration device as shown in Figure 1 can be used to perform continuous multi-surface two-phase structure constant temperature vacuum dehydration on the semi-finished product "medium water content crude oil" after the initial separation of sedimentation, including the following step:

[0043] (1) Circulate the heat medium into the inner cavity of the inner heating tube bundle or start the electromagnetic heater, and quickly raise the temperature of the closed multi-surface constant temperature material cavity formed by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com