Method for producing ordered mesoporous polymer, material with carbon element and composite material in macro amount

A composite material and polymer technology, applied in the fields of mesoporous polymers, carbon materials and composite materials, can solve the problems of low space utilization, complicated operation, long reaction cycle, etc., to simplify the production process, optimize the production conditions, produce Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1, taking phenol and formaldehyde to form a phenolic resin polymer precursor as an example, its preparation is as follows: 305g of phenol is melted at 40-42°C, then 52g of sodium hydroxide solution with a concentration of 25% by mass is added and stirred evenly, Then add 530g of formaldehyde solution with a mass percentage concentration of 37%, and polymerize in a water bath at 65-75°C for 70 minutes. After cooling to room temperature, neutralize to neutral with 32g of concentrated hydrochloric acid. Water was removed by pressure distillation to obtain 520 g of polymer precursor (phenolic resin) (molecular weight 200-500). The obtained polymer precursor (phenolic resin) was dissolved in 780 g of ethanol to obtain an ethanol solution with a mass percent concentration of 40% of the polymer precursor (phenolic resin) used in the reaction.

Embodiment 2

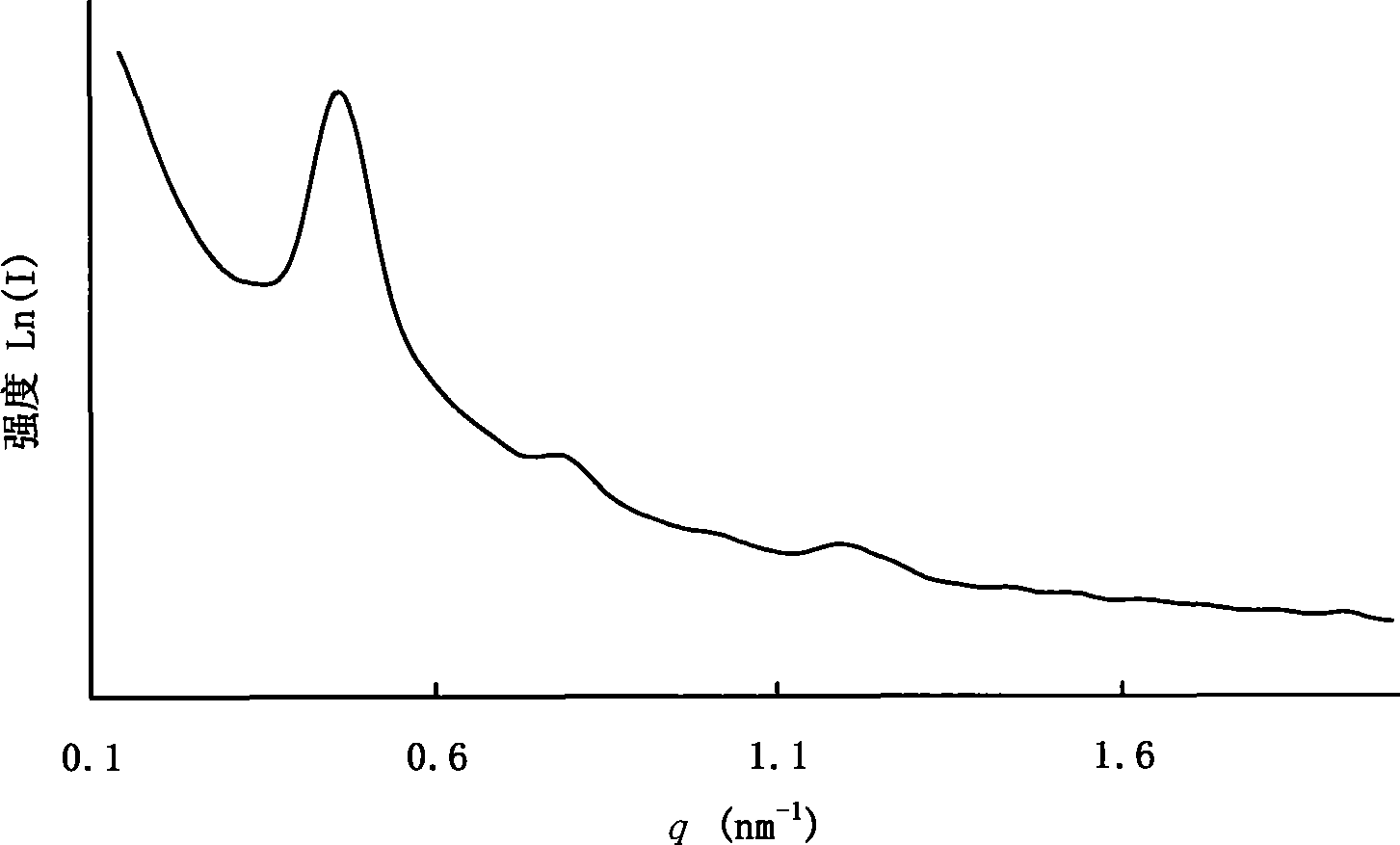

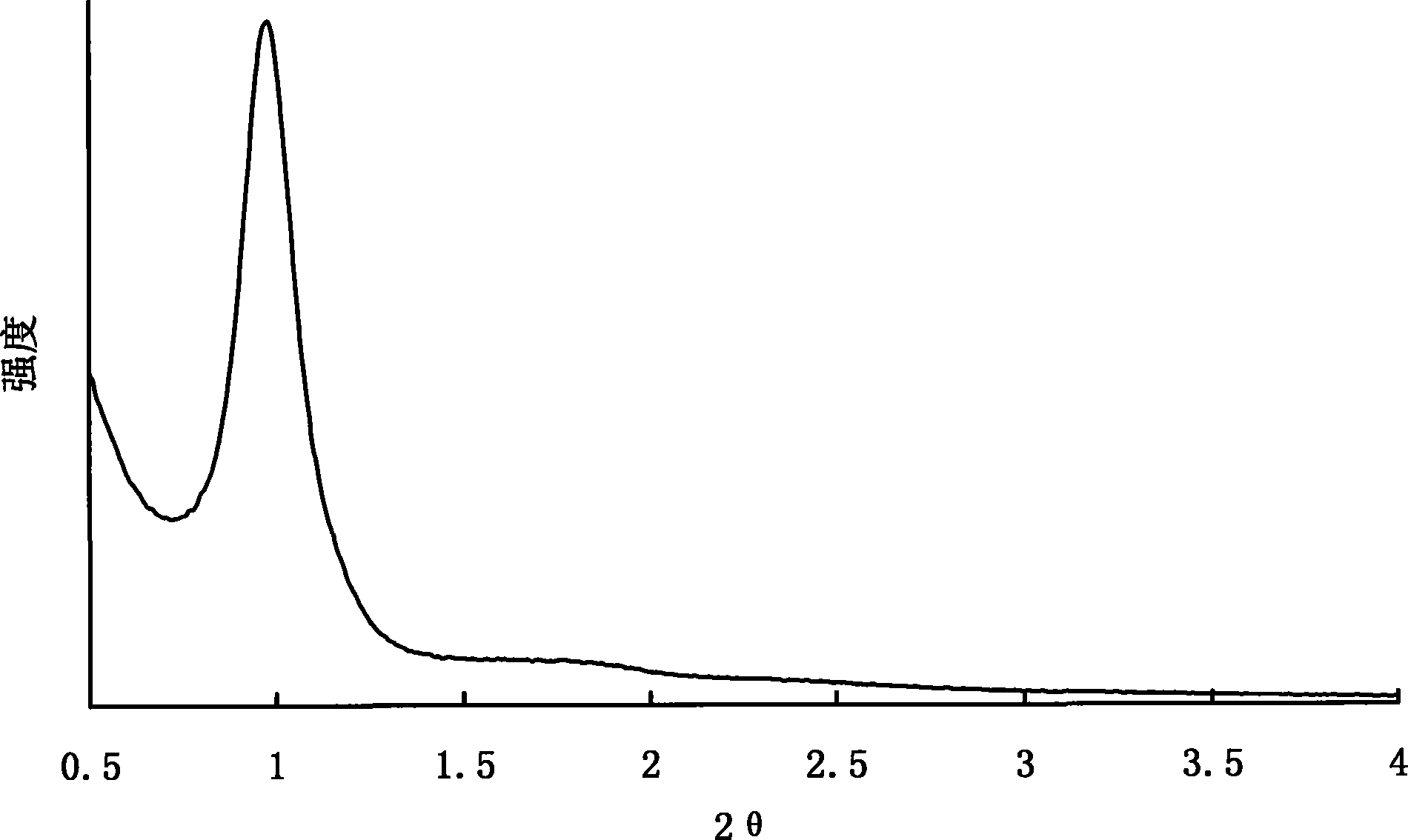

[0044] Example 2, using the triblock copolymer F127 as the structure directing agent system, the steps of preparing the mesoporous carbon material are as follows: 20g F127 is uniformly dispersed in 200g ethanol; The ethanol solution was mixed, and the reaction sol was obtained after magnetic stirring at 30°C for 60 minutes, and then the reaction sol was attached to a volume of 1800cm 3 , the density is 0.02g / cm 3 Polyether polyurethane sponge. The solvent was evaporated for 6 hours at 32°C. The obtained sponge was thermally polymerized in an oven at 100° C. for 20 hours to obtain 75 g of a material composed of F127 / polymer / sponge (99% yield). Its small-angle X-ray scattering spectrum (SAXS) is attached figure 1 As shown, it has a two-dimensional hexagonal channel structure. Then put the sponge in a nitrogen-protected tube furnace and bake at 620° C. for 3 hours with a heating rate of 1° C. / min to obtain 30 g of mesoporous carbon material. The small-angle X-ray scattering ...

Embodiment 3

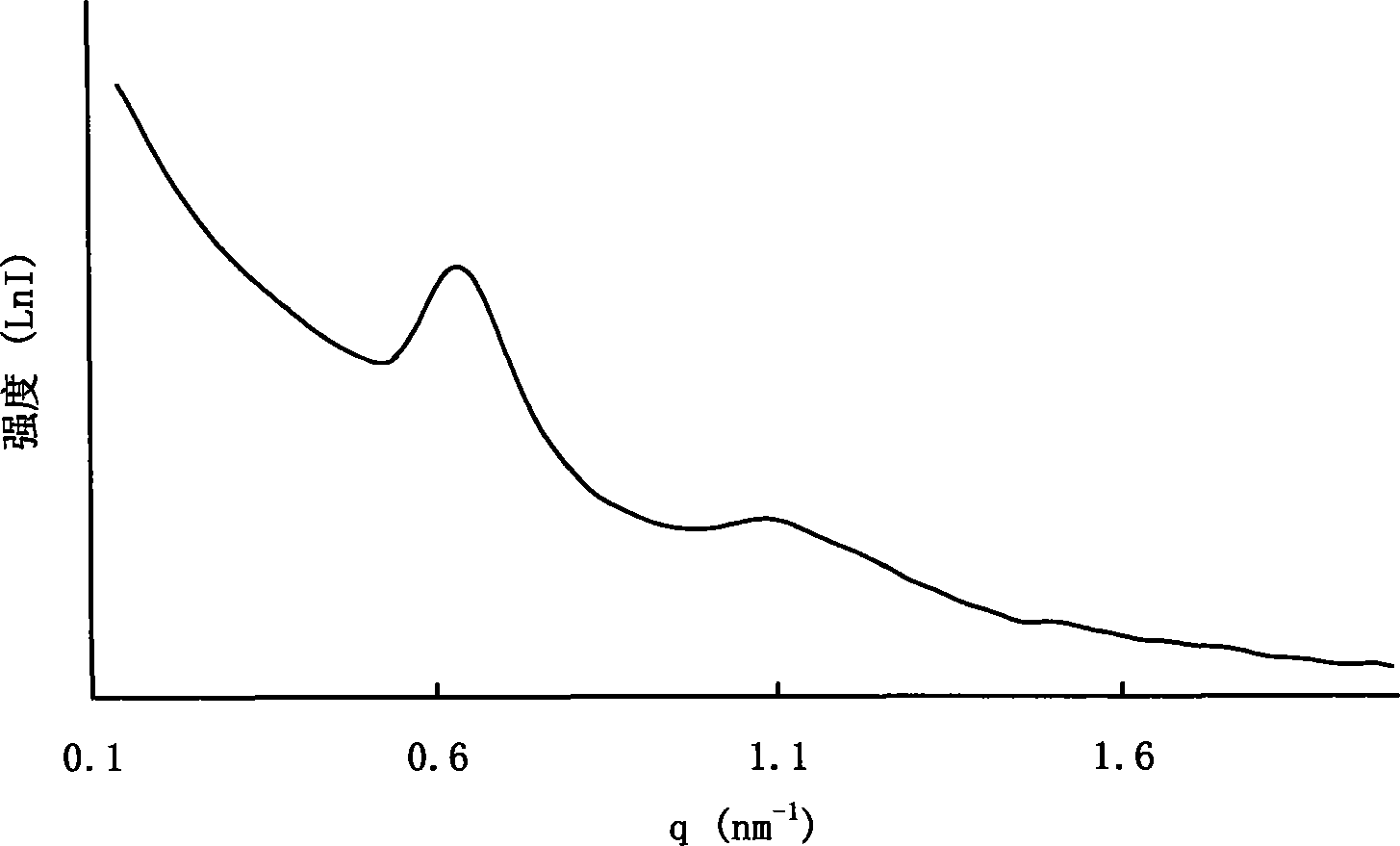

[0045] Example 3, using tri-block copolymer F127 as a structure directing agent, the steps of synthesizing mesoporous polymer materials and carbon materials are as follows: 100g F127 is uniformly dispersed in 1500g ethanol; then mixed with 200g phenolic resin polymer precursor 500g of ethanol solution was mixed, and the reaction sol was prepared after stirring with a magnetic stirrer at 25°C for 90 minutes; then the reaction sol was attached to a volume of 14000cm 3 , the density is 0.02g / cm 3 The solvent was evaporated at 30° C. for 7 hours on a polyether polyurethane sponge. The obtained sponge was placed in an oven at 100° C. for static thermal polymerization treatment for 24 hours to obtain 580 g of a material composed of F127 / polymer / sponge (99% yield). The sponge is then placed in a vacuum tube furnace and roasted at 350° C. for 3.5 hours (vacuum degree is -0.1 MPa), and the heating rate is 1° C. / min to remove the surfactant template agent, and obtain 297 g of mesoporou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com