Arc-extinction electric contact part based on micro-electronic mechanical technology

A micro-electronic mechanical and electrical contact technology, applied in the direction of electrical components, circuits, electrical switches, etc., can solve the problems of reducing reliability and arc extinguishing ability, reducing device yield, increasing manufacturing cost, etc. The effect of low loss and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

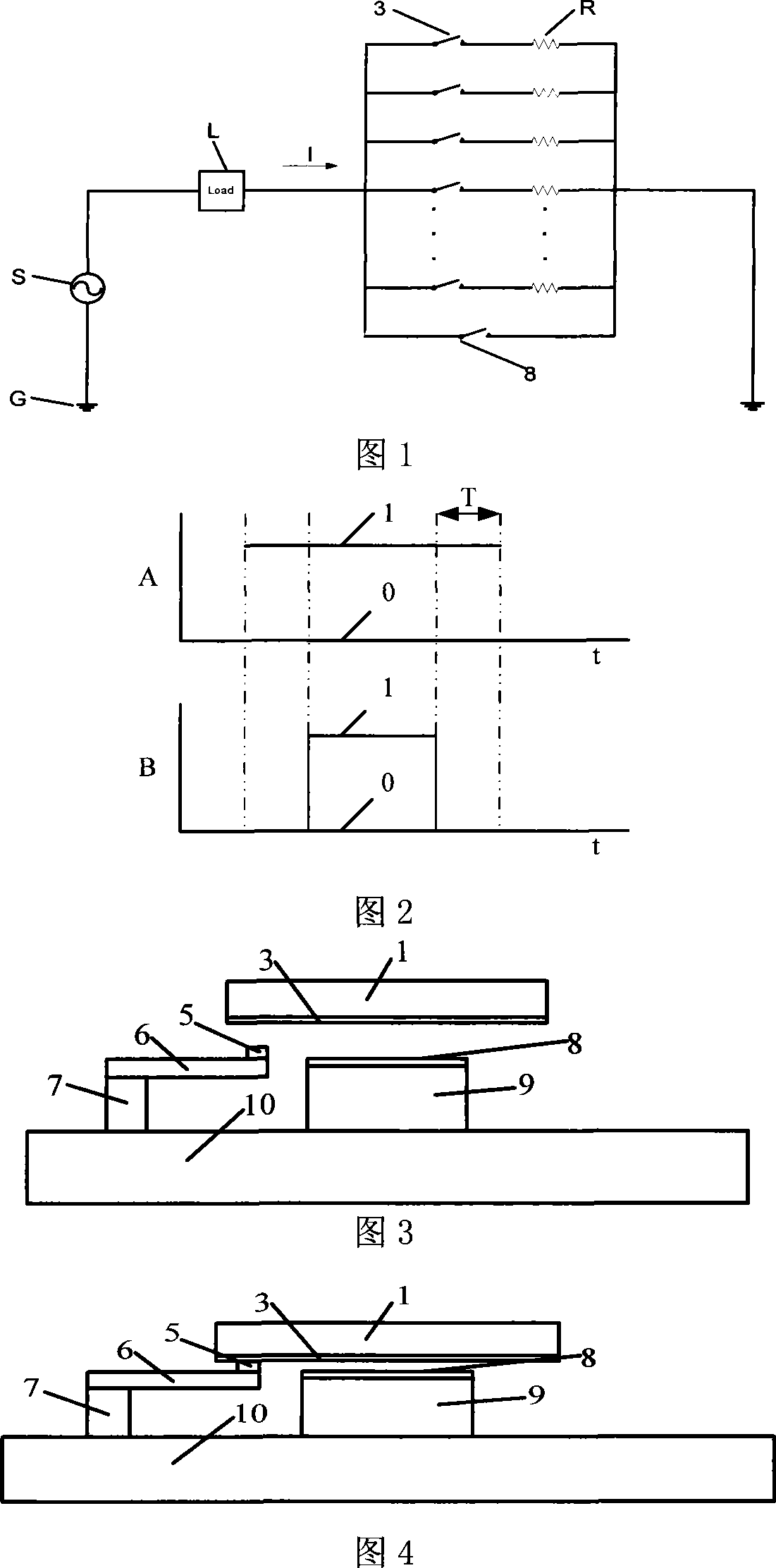

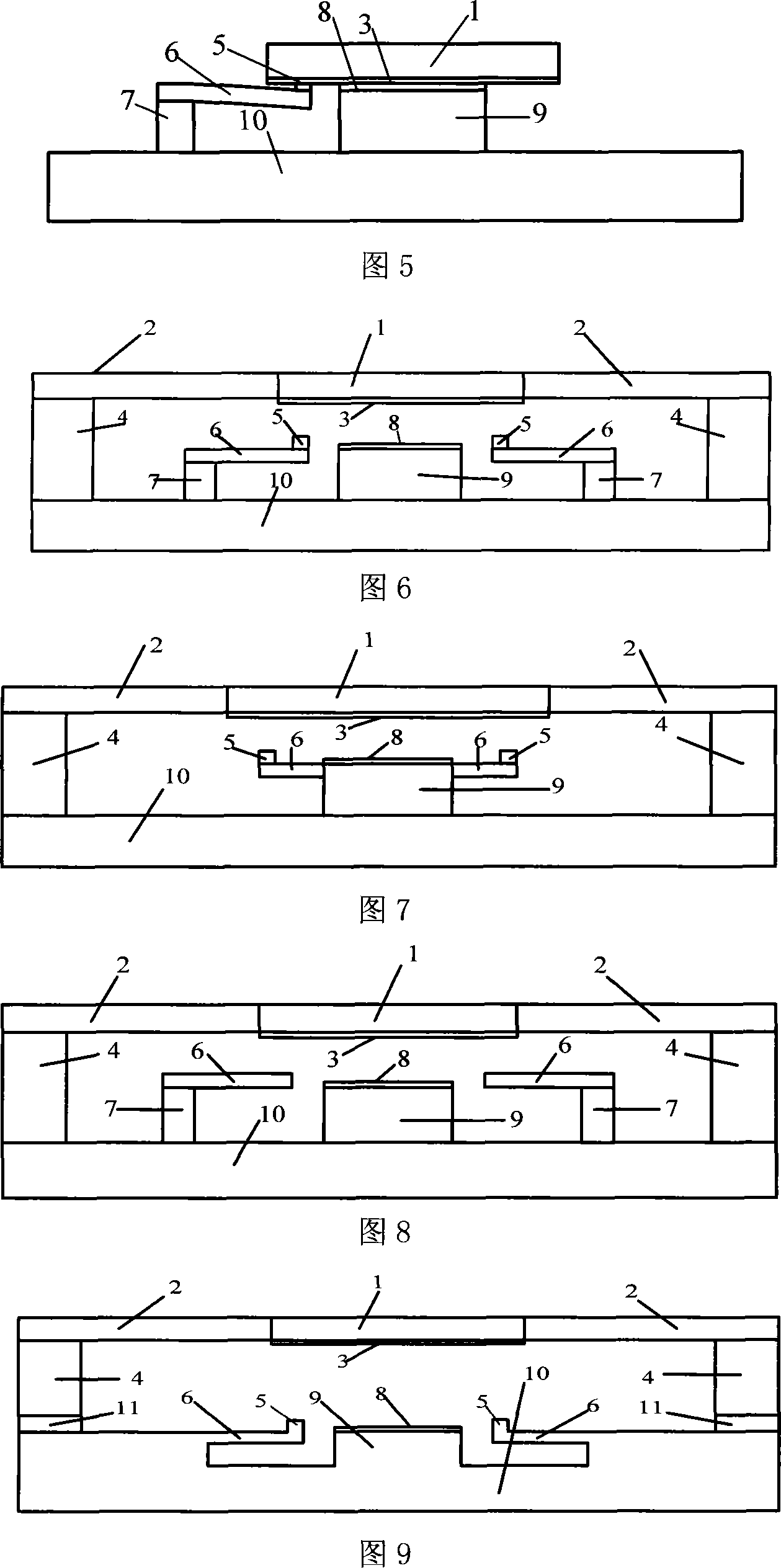

Embodiment 1

[0051] As shown in FIG. 6 , the height of the cantilever beam 6 is the same as that of the lower electrode 9 , and the auxiliary contact 5 is formed on the cantilever beam 6 . The on-off time difference between the auxiliary contact 5 and the main contact 8 is realized by the height of the auxiliary contact 5. The number of current limiting resistors and cantilever beams 6 are both 24, the resistance value is 240Ω, the upper electrode 1, the support body 2, the connecting column 4, The cantilever beam 6, the cantilever beam support 7 and the lower electrode 9 are all made of nickel; the substrate structure 10 is glass; the upper electrode contact 3, the auxiliary contact 5 and the main contact 8 are all made of gold; and the resistor is made of titanium. The specific implementation method is as follows: firstly sputter a 500nm titanium film on the glass sheet, then pattern the resistor by RIE dry etching or HF wet etching, secondly sputter a Cu / Cr seed layer with a thickness of...

Embodiment 2

[0053] As shown in FIG. 7 , the auxiliary contact 5 is still used to realize the successive on-off of the auxiliary contact 5 and the main contact 8 . The number of current limiting resistors and the cantilever beams 6 are both 80 and the resistance value is 80Ω. The difference from the structure of the first embodiment shown in FIG. 6 is that the cantilever beams 6 and the lower electrode 9 are fabricated together. The materials used are also different, the support body 2 is made of SU-8 glue; the upper electrode 1, the connecting column 4, the cantilever beam 6 and the cantilever beam support 7 are all made of nickel; the lower electrode 9 is made of copper; the substrate structure 10 is a silicon wafer; The upper electrode contact 3 is made of silver-palladium alloy; the auxiliary contact 5 and the main contact 8 are made of gold-nickel alloy; and the resistor is made of chromium. The specific implementation method is as follows: firstly, a silicon dioxide insulating layer ...

Embodiment 3

[0055] As shown in FIG. 8 , by increasing the height of the cantilever beam support 4 or the height of the cantilever beam 6 to realize the successive on-off of the auxiliary contact 5 and the main contact 8, the number of the current limiting resistor and the cantilever beam 6 are both 100, and the resistance value 300Ω. Only examples of the heightened cantilever beam support 4 are listed below. The cantilever beam 6 is slightly higher than the lower electrode 9 , and the cantilever beam 6 itself serves as the auxiliary contact 5 . The on-off time difference between the auxiliary contact 5 and the main contact 8 is realized by the height difference between the cantilever beam 6 and the lower electrode 9 . The upper electrode 1 is made of iron-nickel alloy, and the lower electrode 9 is made of copper; the support body 2 is made of polyimide; the connecting column 4 and the cantilever beam support 7 are made of iron-nickel alloy; the cantilever beam 6 is made of nickel; the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com