Photosensitive resin composition for liquid crystal display element, color filter using the same, process for manufacture of the color filter, and liquid crystal display element

A liquid crystal display element and photosensitive resin technology, which is applied to photosensitive materials, optical filters, and patterned surface photoengraving processes for opto-mechanical equipment, to achieve high-speed response to display unevenness and suppress display unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0511] (embodiment 1): transfer method

[0512] In this example, an MVA-mode liquid crystal display device as configured in FIG. 19 was produced.

[0513] (Production of photosensitive resin transfer material)

[0514] On a polyethylene terephthalate film temporary support (PET temporary support) with a thickness of 75 μm, use a slit-shaped nozzle to apply and dry the thermoplastic resin layer coating liquid composed of the following recipe H1 to form a thermoplastic resin layer. Next, a coating liquid for an intermediate layer having the following formulation P1 was applied and dried on the thermoplastic resin layer, and an intermediate layer (oxygen barrier film) was laminated. Furthermore, the photosensitive resin composition K1 of the composition described in following Table 1 (transfer method) was apply|coated and dried on this intermediate|middle layer, and the photosensitive layer was laminated|stacked. In this way, a thermoplastic resin layer with a dry film thickne...

Embodiment 2

[0695] (Example 2): Coating (liquid resist) method

[0696] -Production of color filters (coating with slit nozzle)-

[0697] -Formation of black (K) pixels-

[0698] An alkali-free glass substrate (hereinafter referred to simply as a glass substrate) having a size of 680×880 mm was cleaned with a UV cleaning device, brushed with a detergent, and ultrasonically cleaned with ultrapure water. The glass substrate was heat-treated at 120° C. for 3 minutes to stabilize the surface state. Then, the glass substrate was cooled, and the temperature was adjusted to 23° C., and then the glass substrate coating machine MH-1600 (manufactured by FIS Japan (Ef·Er·Es Japan) Co., Ltd.) having a slit-shaped nozzle was used to coat the Composition Colored photosensitive resin composition K1. Next, a part of the solvent was dried for 30 seconds using a vacuum dryer VCD (manufactured by Tokyo Ohka Kogyo Co., Ltd.) to lose the fluidity of the coating film, and then prebaked at 120° C. for 3 minu...

Embodiment 3

[0722] Using the same recipe and procedure as in Example 1, RGBK and the photosensitive transfer material for forming a spacer were used, and the exposure method was changed as follows, and a color filter was prepared in the same procedure as in Example 1, except that .

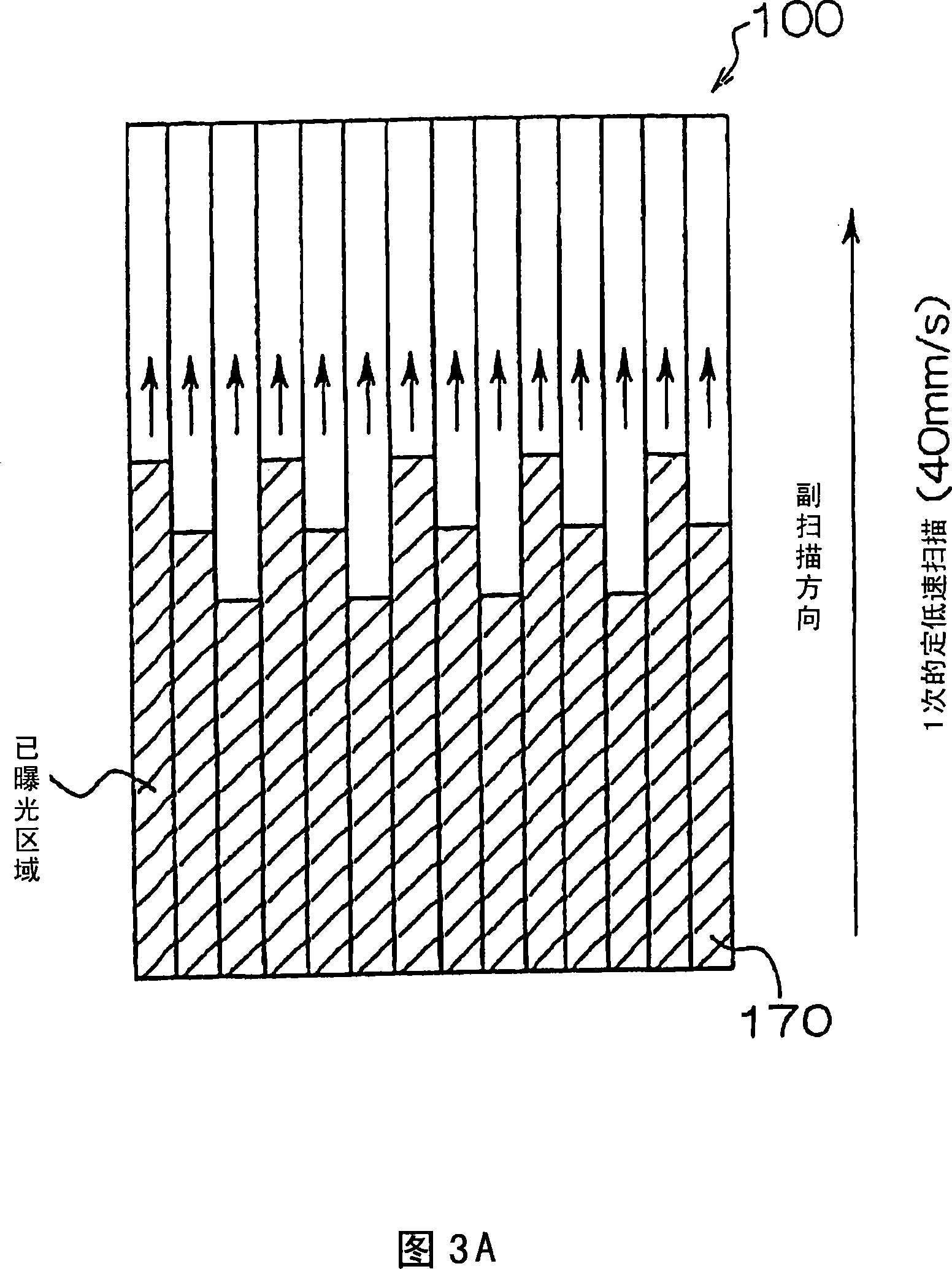

[0723] A modified exposure method is used; a polygon mirror type exposure device that converts light emitted from a 405nm LD into scanning light by rotating a polygon mirror with a hexagonal column. The scanning speed of the polygon mirror on the substrate was 300 m / sec.

[0724] at 0.2mJ / cm 2 , expose a 20 cm x 30 cm area of the substrate for 20 seconds. In order to increase the exposure amount, the rotation speed of the polygon mirror is adjusted to be constant, and the moving speed of the substrate moving at right angles to the scanning direction of the polygon mirror is slowed down.

[0725] As can be seen from Table 2, even in this Example 3, the photosensitive spacer was formed at the same photosen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com