Polyethylene terephthalate solid-state polycondensation technique

A polyethylene terephthalate and solid-phase polycondensation technology, which is applied in the field of polyester synthesis, can solve problems such as unreasonable energy utilization and unapplied solid-phase polycondensation technology, and achieve considerable economic benefits, remarkable energy-saving effects, and saving The effect of heating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

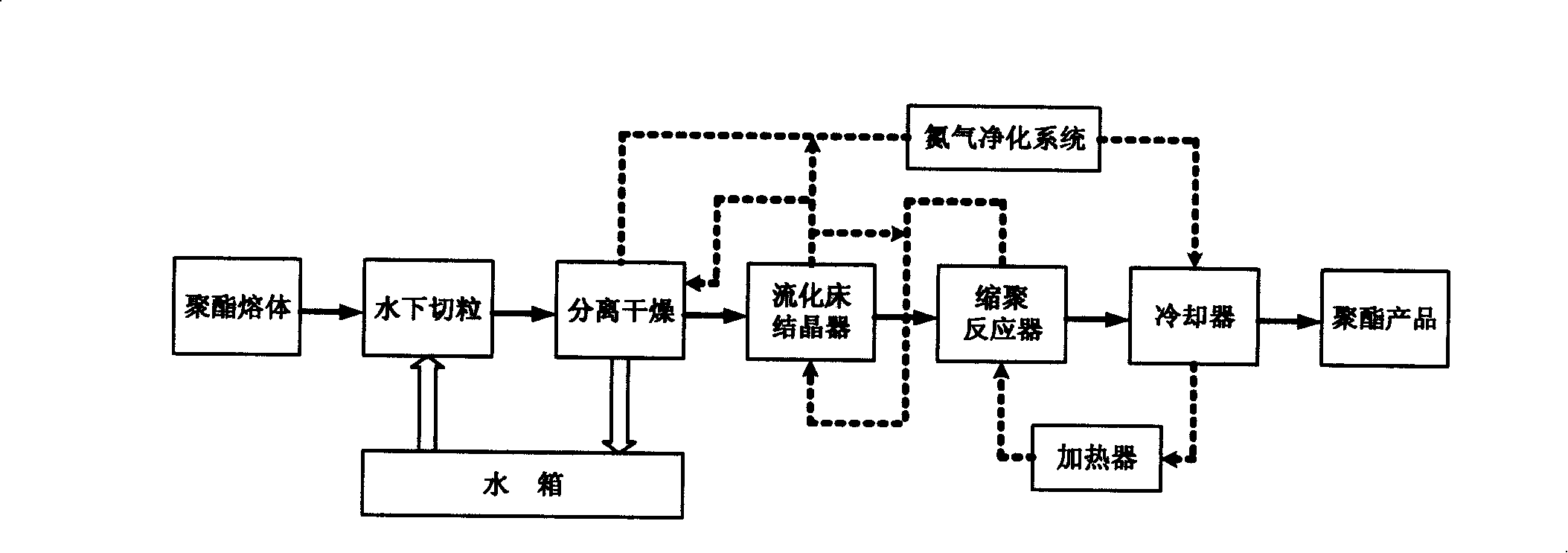

[0020] PET melt 125000kg / hr (η=0.62dl / g) is cut into pellets in hot water, the temperature of hot water is 95°C, cut into cylindrical particles with a diameter of 3.6mm, and the particles are quickly transported to the separation dryer with the water flow, Separation and drying are carried out, the water velocity is 5m / s, the total residence time of the particles in the pelletizing chamber and the separation drier is 2 seconds, the nitrogen flow rate (m 3 / hr): slice flow rate (kg / hr)=0.3; the temperature of the slice at the outlet of the separation drier is 183°C, enters the fluidized bed crystallizer, and passes into the nitrogen flow rate of the crystallizer (m 3 / hr): slice flow rate (kg / hr)=2.4, nitrogen temperature is 200° C., 85% of the nitrogen from the fluidized bed crystallizer is recycled, and 13% enters the separation drier. The residence time in the crystallizer is 10min, the slice outlet crystallinity 43% (density method), 210 ℃ of temperatures; The residence tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com