Pneumatic electrothermal stewing implement

A technology for cooking utensils and electric heaters, which is applied to cooking utensils, household utensils, kitchen utensils, etc., can solve the problems of high cost, single function and high energy consumption, and achieve the effects of saving energy, improving stability and reducing heat of vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

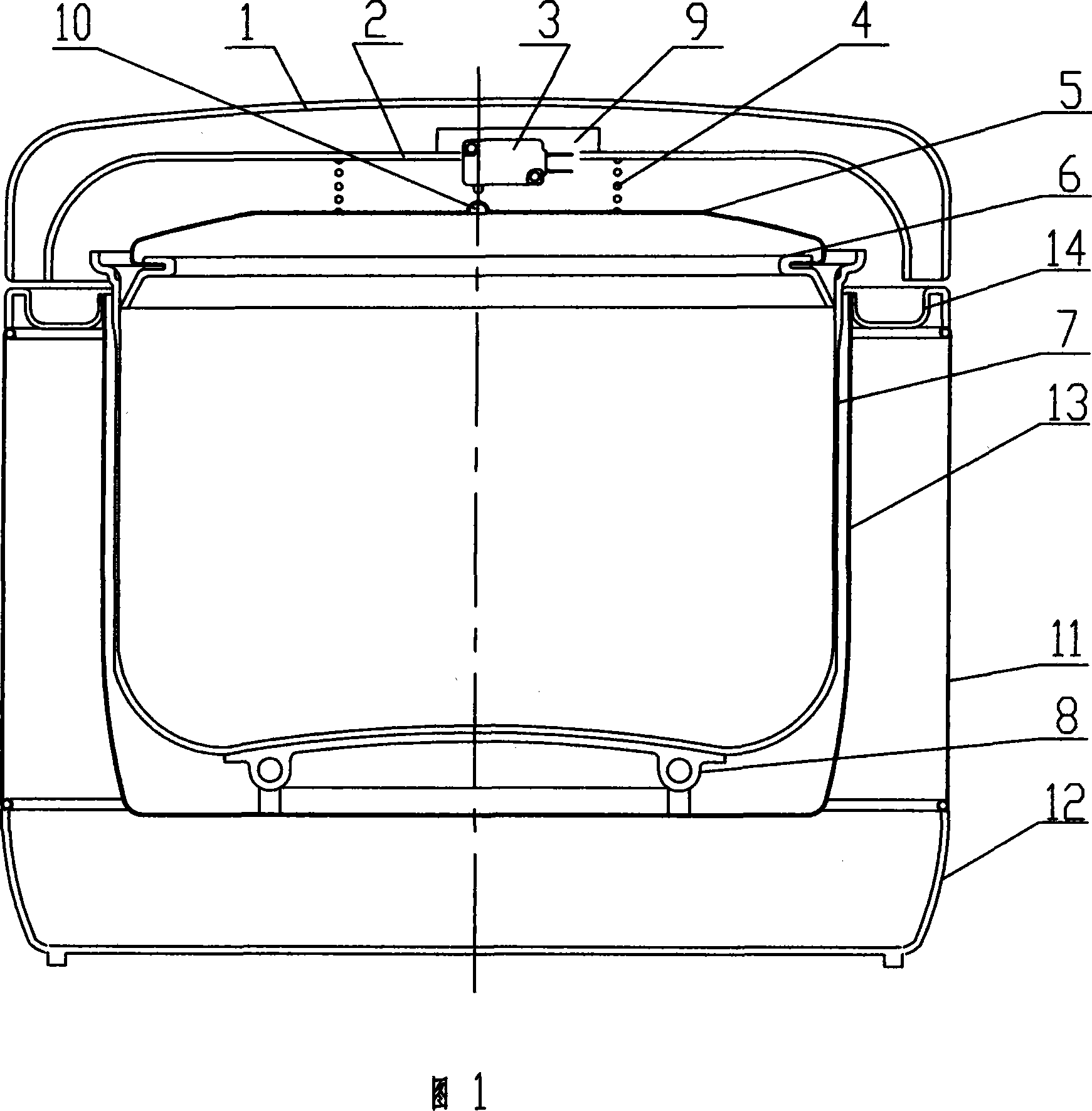

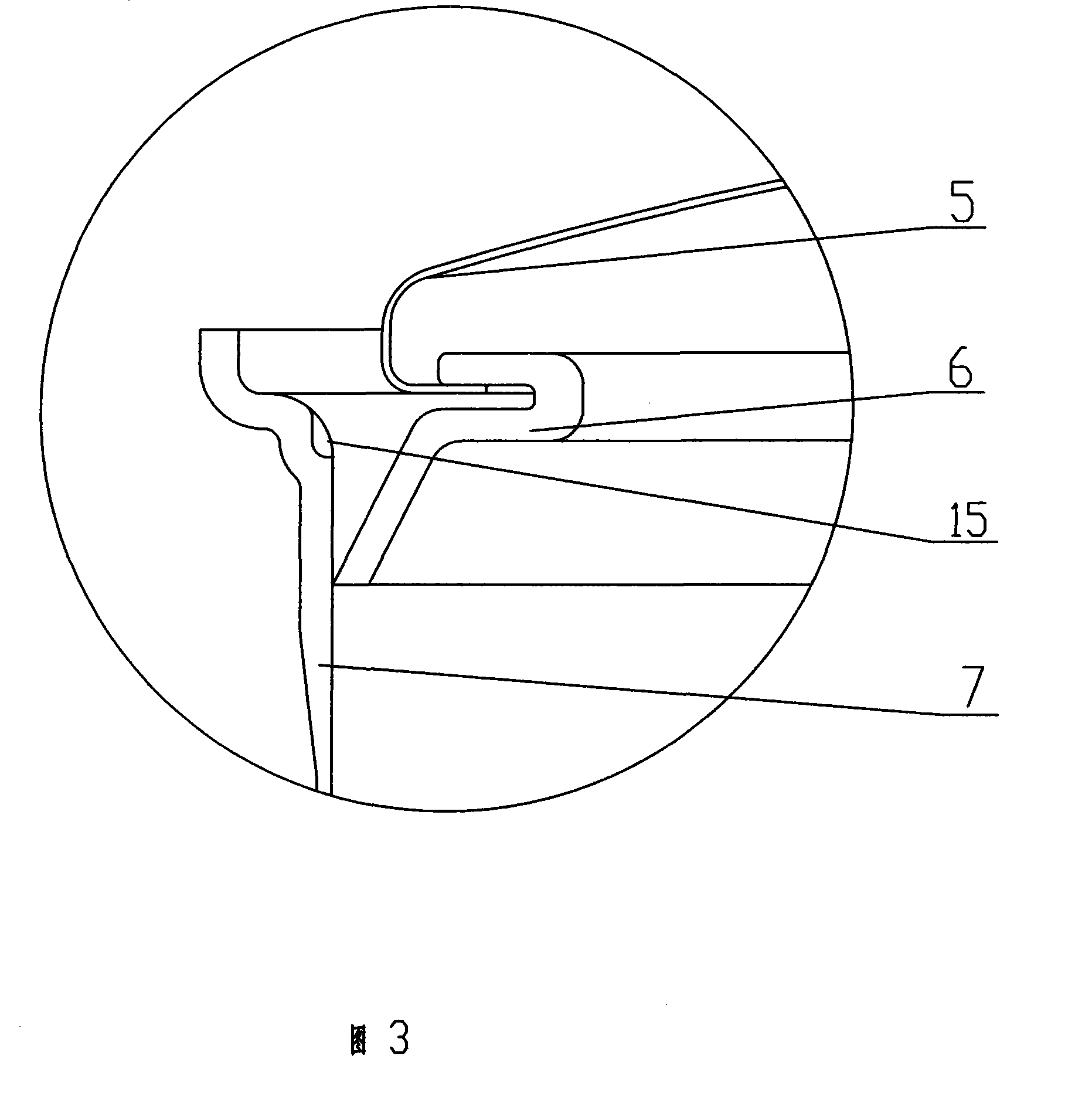

[0018] Embodiment 1: the overall structural design of product of the present invention, except implementing relevant technical parts with this technical scheme, other parts are as plastic cover 1, plastic cover liner 2, outer pot 13, shell 11, base 12 and pot cover parts and The connection structure of the inner pot parts, etc., can be designed with reference to the relevant parts of the existing conjoined electric rice cooker product. In practice, the pot lid 5 can be made of a high-quality stainless steel plate or high-quality alloy aluminum plate with a thickness of about 0.3 mm, and its outer edge size and shape should cooperate with the sealing ring 6 to meet the requirements of dynamic sealing connection. Switch 3 can select the monostable type microswitch that adopts on the existing electric cooker for use, and its feature is to change heating state with the change of driving force, it is fixedly arranged on the plastic cover lining 2 and notices waterproof. At the posi...

Embodiment 2

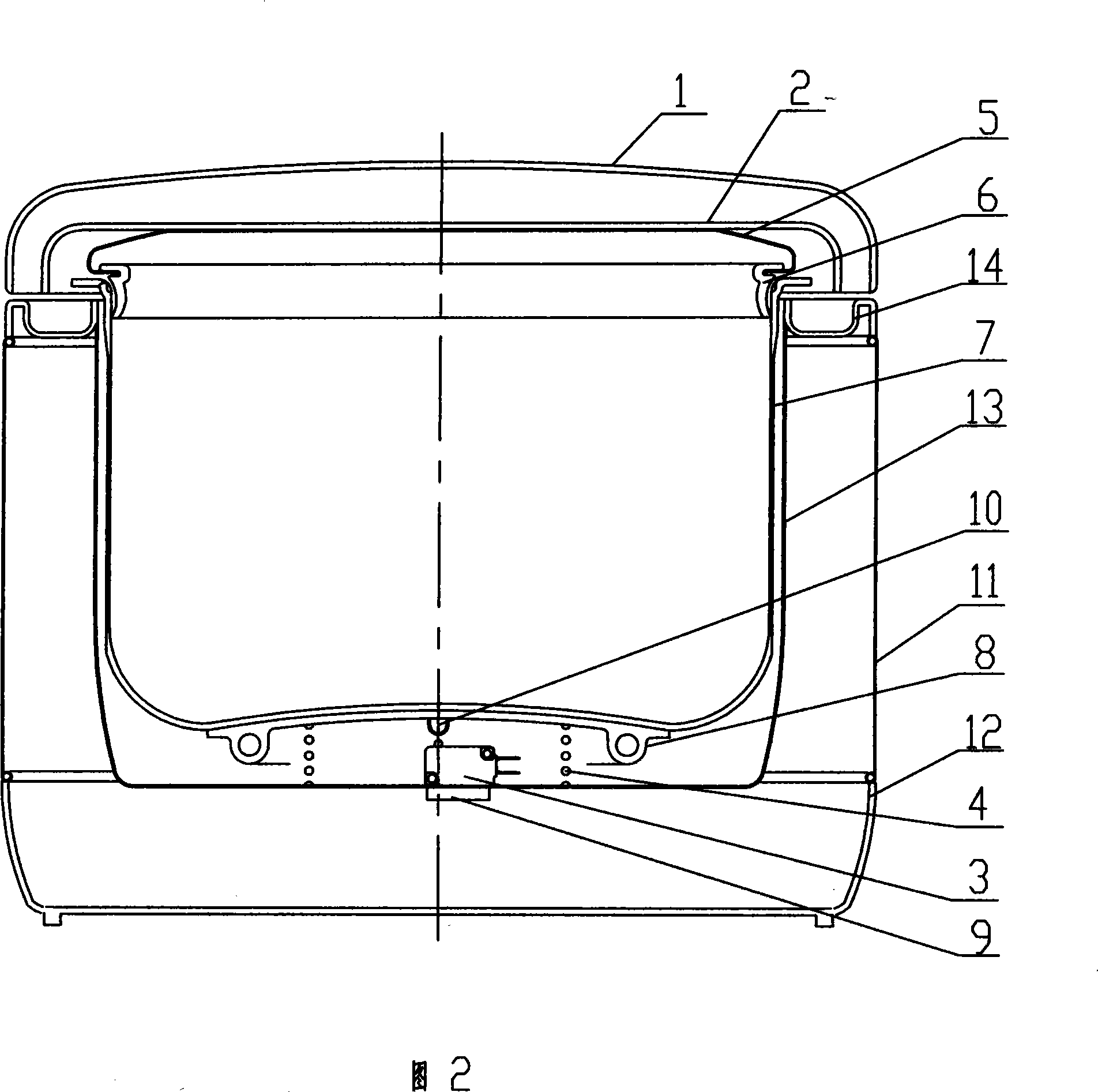

[0021] Embodiment 2: The difference between Embodiment 2 and Embodiment 1 is that the steam power control device is arranged below the electric heater 8 . Since the bottom of the inner pot 7 is in contact with the upper surface of the electric heater 8, the steam power in the pot can be transmitted to the electric heater 8 through the bottom of the inner pot, so that it moves downwards with the inner pot 7, thereby realizing the present invention technical solutions. When implementing the scheme of placing the steam power control device below, in order to offset the sum of the gravity of the inner pot 7 (gravity about 500g·f), food (gravity up to 4kg·f), electric heater 8 (gravity about 250g·f), etc., it is necessary to set The elastic element 4 (whose elastic force should be about 5kg·f) realizes the force balance requirement, so as to obtain the required starting control sensitivity. Such as figure 2 As shown, one end of the elastic element 4 is arranged below the electri...

Embodiment 3

[0022] Embodiment 3: The electric heater 8 in the present invention can be an electromagnetic electric heater or a radiation electric heater. The inner pot 7 is not in contact with the electric heater 8 for heat transfer. When adopting this technical solution, the following options can be selected: one is that the steam power control device is placed on the top, and the setting method and position can refer to embodiment 1. The pot edge of inner pot 7 is supported on the pot edge of outer pot 13 (or the corresponding position of outer pot cover 14), and in work, inner pot 7 is in relatively static state. The electric heater 8 is fixedly arranged between the bottom of the inner pot 7 and the bottom of the outer pot 13 . The 2nd, steam power control device is put down, and pot cover 5 is in static state. Elastic element 4 is arranged at the bottom of outer pot 13, and inner pot 7 is mounted on elastic element 4. In practice, the diameter-reducing part of inner pot 7 bottom can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com