Low birefringent copolymer

A technology of copolymer and acrylic acid, which is applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of coloring, thermal yellowing of resin, etc., and achieve the effects of excellent heat resistance, excellent transparency, and low coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0094]

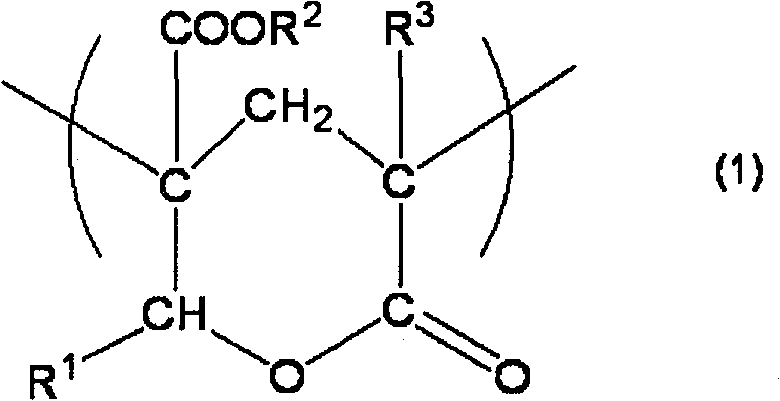

[0095] The preparation of the acrylic copolymer is not particularly limited. First, in the case of an acrylic copolymer having a structural unit providing a negative retardation and a lactone ring structure as a structural unit providing a positive retardation in the molecular chain, An acrylic copolymer (a) having a structural unit providing a negative retardation in the molecular chain and a hydroxyl group and an ester group in the molecular chain is obtained from the polymerization process, and then the obtained acrylic copolymer (a) is subjected to heat treatment, It is obtained by performing a cyclization condensation step of introducing a lactone ring structure that provides a positive phase difference in an acrylic copolymer.

[0096] At this time, in the polymerization step, for example, the monomer component of the monomer represented by the following formula (6) and the monomer represented by the following formula (7) can be mixed to obtain the in the molecular ...

Embodiment 1

[0228] First, a 30-liter reaction vessel with a stirring device, temperature sensor, cooling tube, and nitrogen introduction tube is charged with 7 kg of methyl methacrylate, 2 kg of 2-(hydroxymethyl) acrylate, and 1 kg of styrene. , 10kg of methyl isobutyl ketone, 5g of n-dodecyl mercaptan.

[0229] Nitrogen was introduced into the reaction vessel and the temperature was raised to 105°C. Under reflux, 5 g of tert-amyl 3,5,5-trimethylhexanoate was added as a polymerization initiator. At the same time, it was added dropwise to 230 g of methylbenzene over 2 hours. A solution of 10 g of tert-amyl 3,5,5-trimethylhexanoate is dissolved in the base isobutyl ketone, and solution polymerization is carried out at about 105-120°C under reflux, and then maturing for 4 hours.

[0230] 30 g of stearyl phosphate / di(octadecyl) phosphate mixture (Phoslex A-18, manufactured by Sakai Chemical Industry Co., Ltd.) was added to the obtained acrylic copolymer solution, and the mixture was refluxed at ab...

Embodiment 2

[0261] First, a 30-liter reaction vessel with a stirring device, a temperature sensor, a cooling tube, and a nitrogen introduction tube was charged with 7950 g of methyl methacrylate, 1500 g of 2-(hydroxymethyl) acrylate, and 550 g of styrene. , 10,000g of toluene.

[0262] Nitrogen was introduced into the reaction vessel and the temperature was raised to 105°C. 12g of tert-amyl peroxyisononanoate as a polymerization initiator was added under reflux. At the same time, 24g of peroxide was dissolved in 136g of toluene over 2 hours. The solution of tert-amyl isononanoate is oxidized, and solution polymerization is performed at about 105-110°C under reflux, and then matured for 4 hours.

[0263] 10 g of octyl phosphate (Phoslex A-8, manufactured by Sakai Chemical Industry Co., Ltd.) was added to the obtained acrylic copolymer solution, and the reaction was subjected to cyclization condensation reaction at about 120°C under pressure for 5 hours. Then, the obtained acrylic copolymer sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com