Grade compression-segmenting heat-taking type steam compression heat pump

A compression heat pump and staged compression technology, which is applied in the direction of compressors with cascaded work, heat pumps, compressors, etc., can solve the problems of unit performance index decline, unit heat transfer temperature difference, low volumetric efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

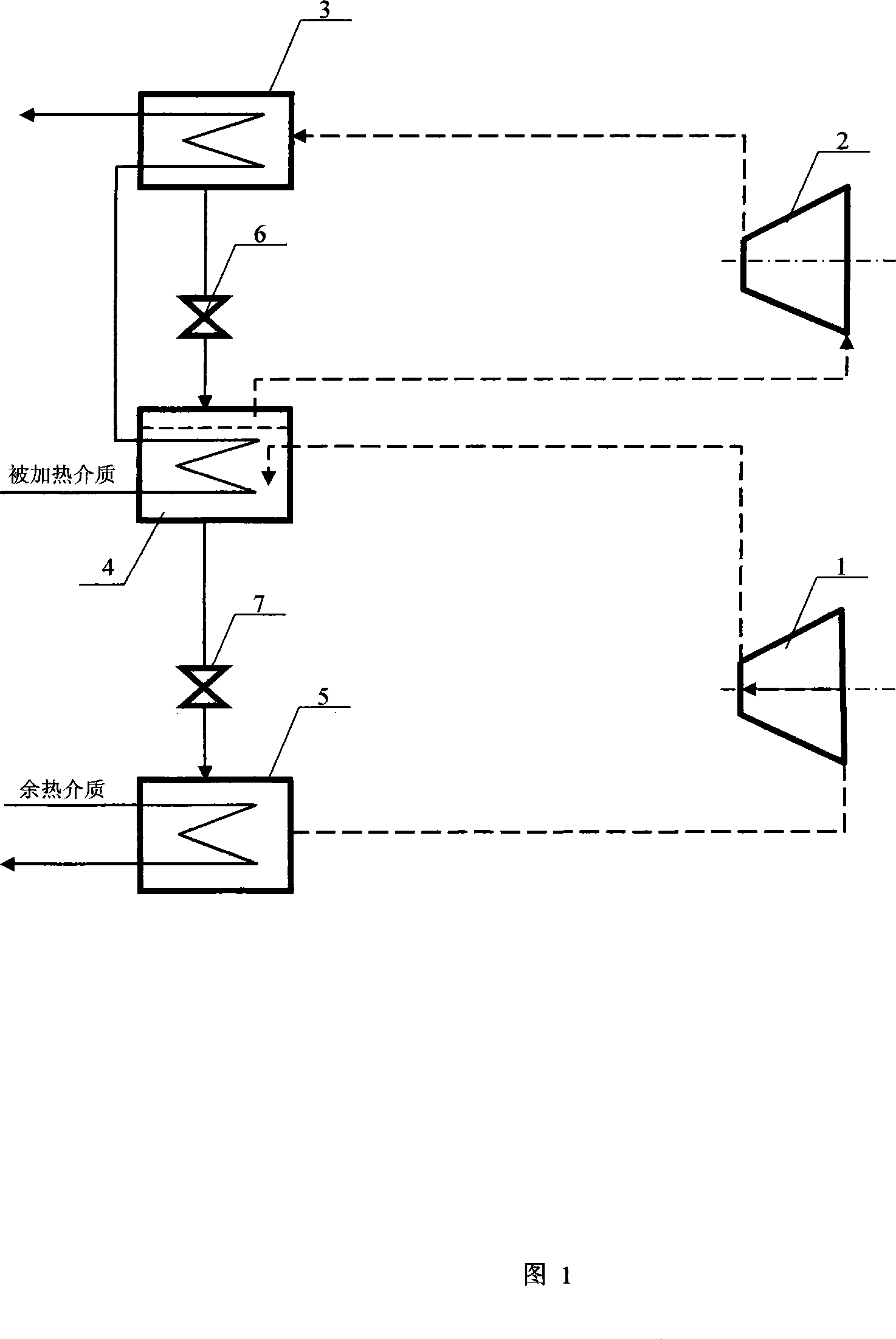

[0025]Fig. 1 is provided according to the present invention, adopts the staged compression of two-stage compression-two-stage heat extraction-stage heat extraction type vapor compression heat pump, it realizes the present invention like this:

[0026] Basic components such as primary compressor (1), primary condenser (4), evaporator (5) and throttling valve (7) constitute the low-temperature section compression-heat extraction heat pump flow and structure——primary compressor (1 ) is connected to the first-stage condenser (4) through the working steam channel, and the first-stage condenser (4) is connected to the evaporator (5) through the throttle valve (7), and the evaporator (5) is also connected to the first-stage compressor through the working steam channel. The machine (1), the evaporator (5) also have pipelines connected to the waste heat medium, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com