Preparation of pre-coated aluminium alloy articles

A technology for aluminum alloy parts and aluminum alloys, which is applied to coatings, surface reaction electrolytic coatings, and devices for coating liquids on surfaces, etc., which can solve problems such as dirty and difficult operation, save costs, and improve corrosion resistance. , technology and cost superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

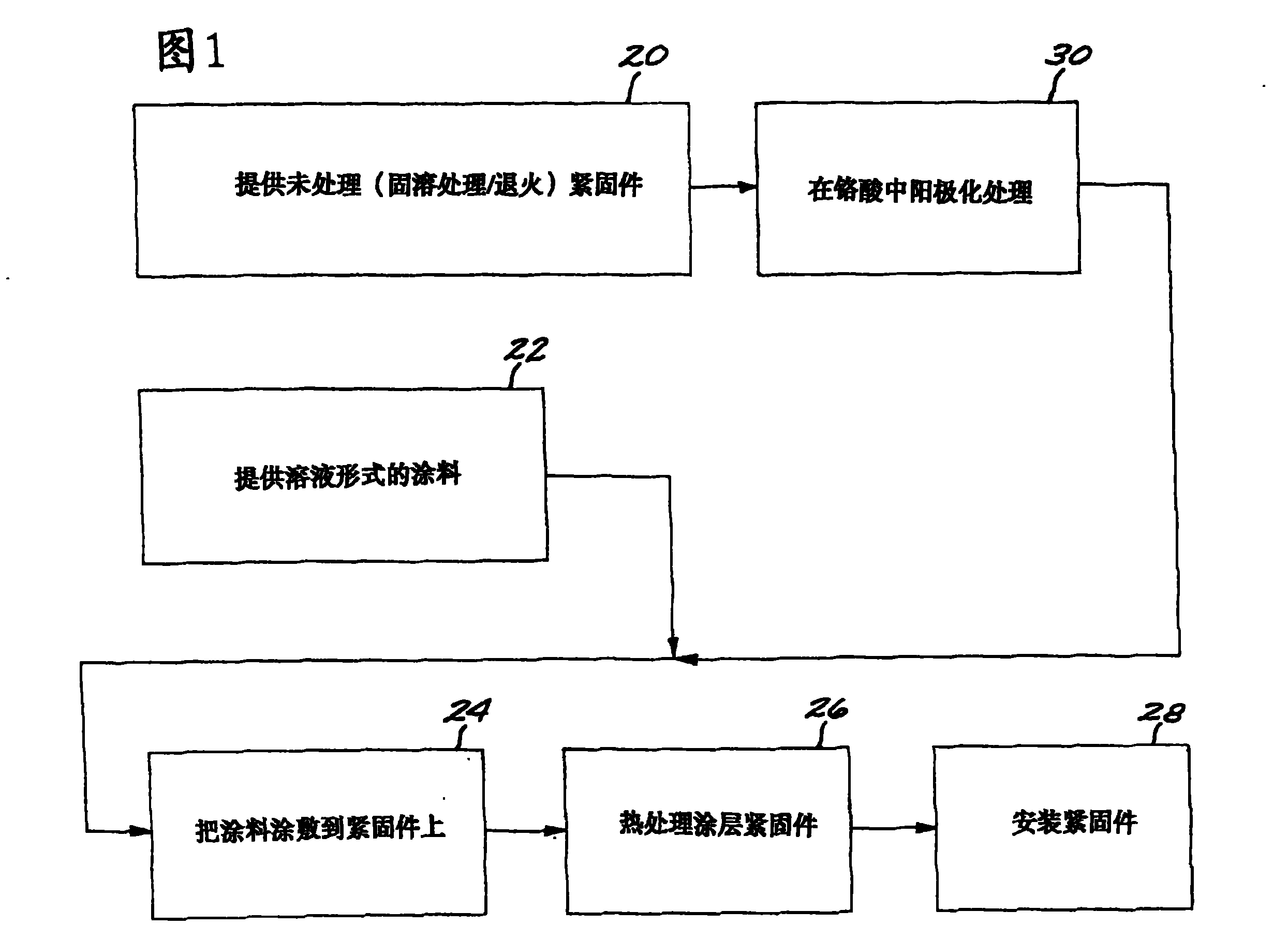

[0021] As shown in Figure 1, an untreated (ie uncoated and annealed) part is first provided. Preferred embodiments of the present invention relate to the preparation of fasteners such as rivets, and the discussion below focuses on these components. The use of the present invention is not limited to fasteners and rivets, rather it has broader application. However its use on fasteners offers certain advantages which will be discussed.

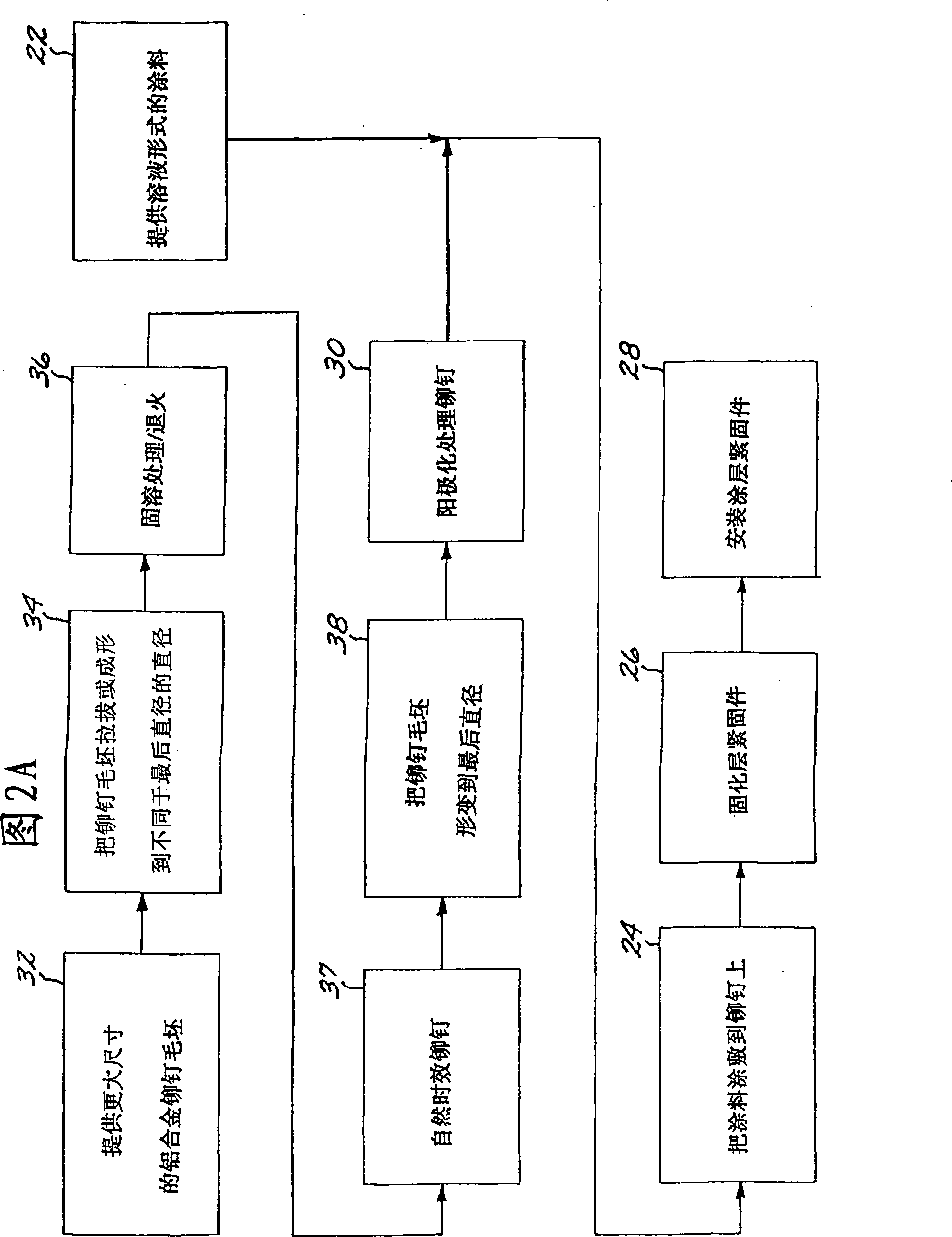

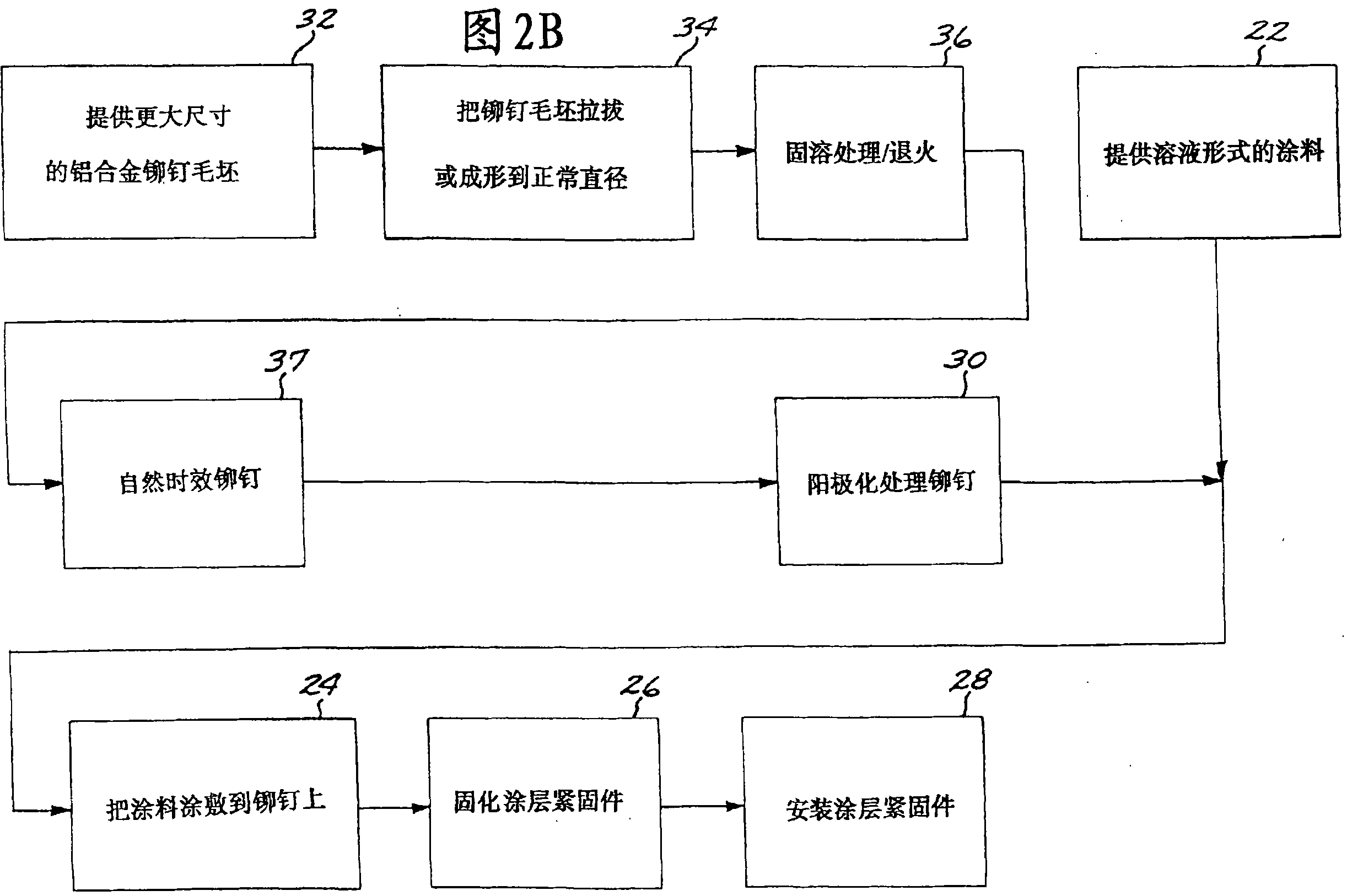

[0022] A rivet 40 is provided, number 20, for use with the present invention on a rivet, fastener or other component machined to its conventional shape and size. FIGS. 4-6 illustrate the installation of a first workpiece 42 to a second workpiece 44 Three types of rivets 40 in intermediate stages, ie after having been mounted to the first and second workpieces but before upset. The rivet 40 in Figure 4 has a preformed nose 46 at one end, the rivet 40' in Figure 5 is an upset rivet without a preformed nose at each end, and the rivet 40" in Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com