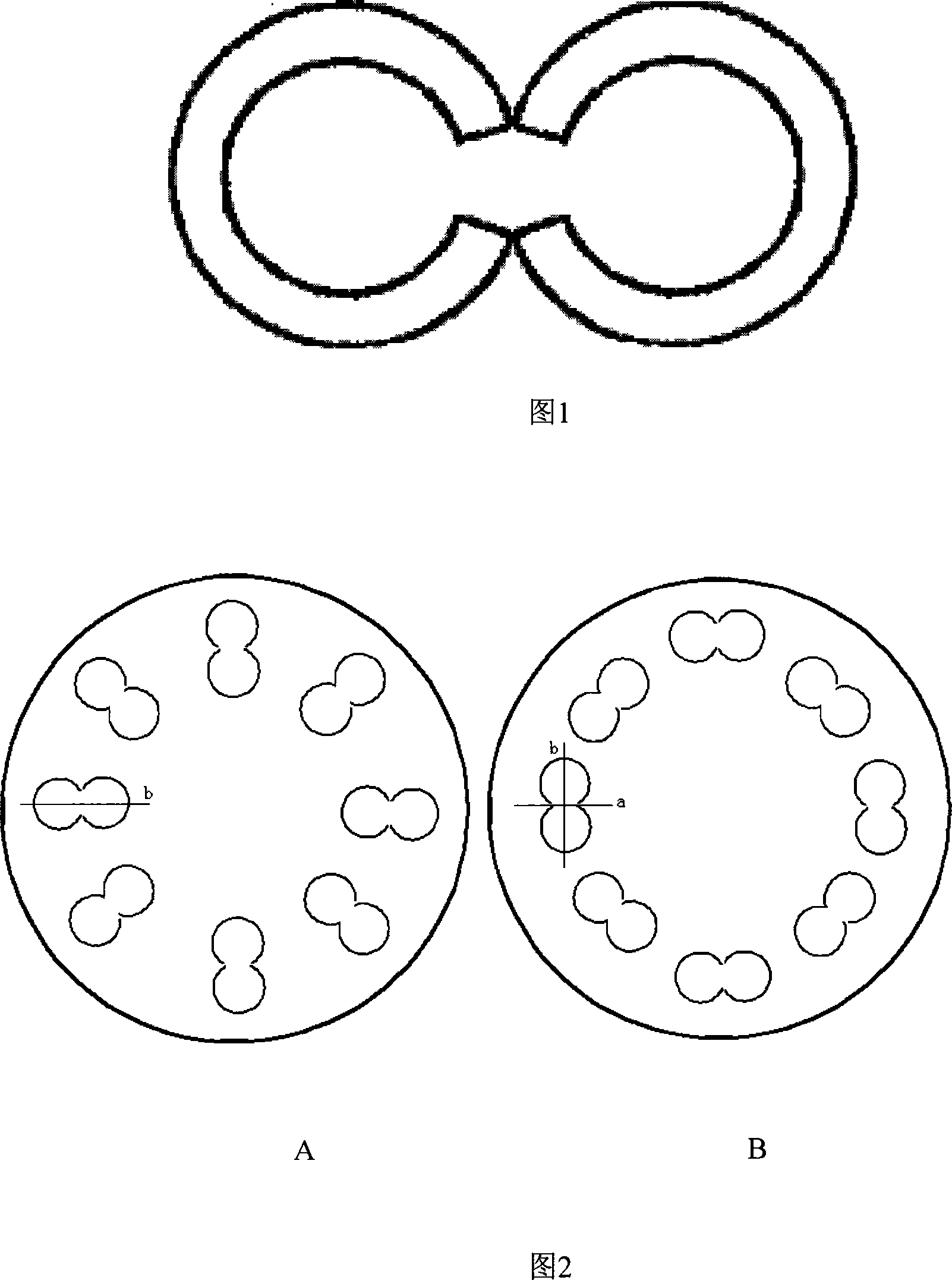

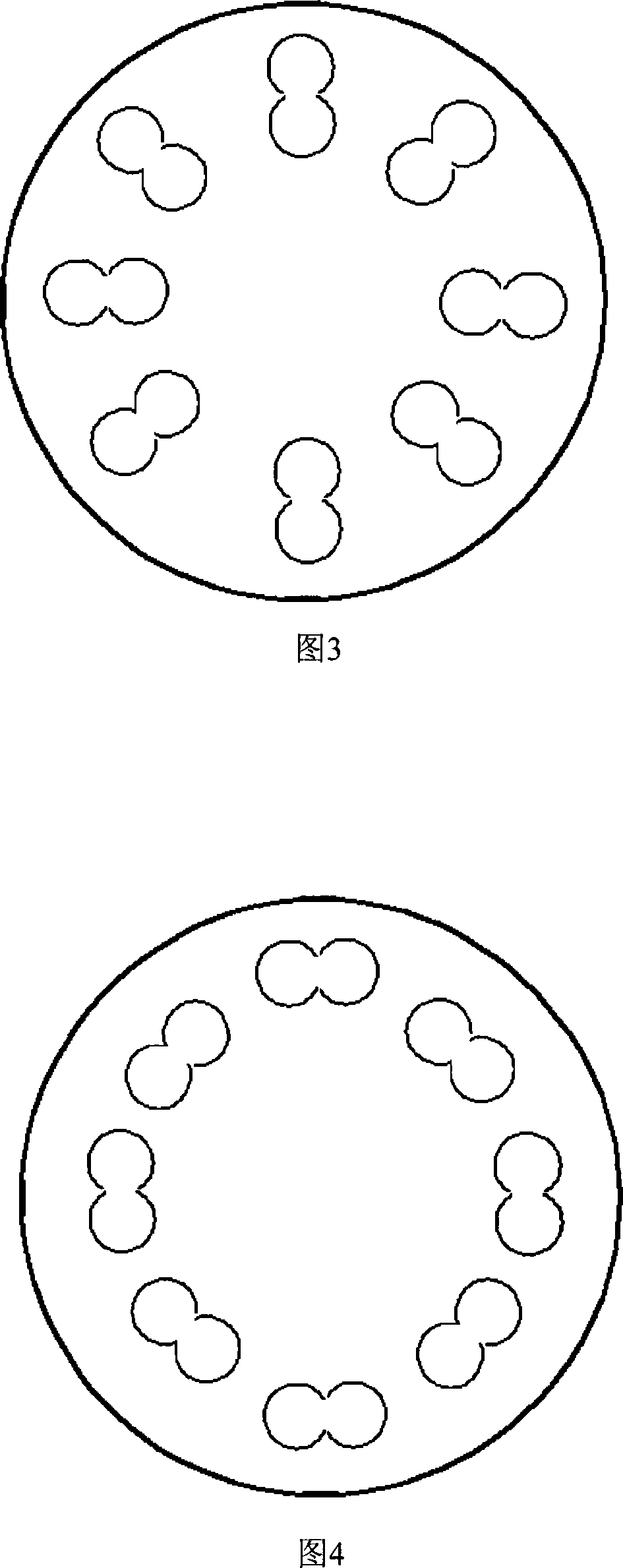

8-shaped pet/PTT hollow fibre and preparing method thereof

A fiber and hollow technology, applied in the field of "8"-shaped PET/PTT hollow fiber and its preparation, can solve the problems of deterioration of tensile properties, poor spinning, unstable hollow fiber, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Production example of "8" shaped PET / PTT hollow staple fiber

[0027] Raw material composition: PET chips (intrinsic viscosity 0.65 dL / g, melting point 260-265°C)

[0028] PTT chip (intrinsic viscosity 0.92 dL / g, melting point 228~233℃)

[0029] Pre-crystallization of PET polyester chips (temperature 170°C, time 3h, drying medium hot air, dew point -70°C) and then drying of two kinds of polyester chips (PET chip drying temperature is 175°C, PTT is 165 °C), according to the set compounding ratio (50:50), they are respectively fed into the twin-screw extruder for melt extrusion, and the melts of the two components use two sets of metering pumps respectively, and enter the composite spinning through the melt pipe. The components are sprayed out from the spinneret, and then cooled by the surrounding air, oiled, wound, dropped into the barrel, bundled, stretched, tensioned and heat-set, oiled, crimped, and cut. Some of the specific spinning process parameters are shown in T...

Embodiment 2

[0034] Production example of "8" shaped PET / PTT hollow DTY long fiber

[0035] Raw material composition: PET chip (intrinsic viscosity 0.65dL / g, melting point 260~265℃)

[0036] PTT chip (intrinsic viscosity 0.92dL / g, melting point 228~233℃)

[0037] Pre-crystallization of PET polyester chips (temperature 170°C, time 3h, drying medium hot air, dew point -70°C) and then drying of two kinds of polyester chips (PET chip drying temperature is 175°C, PTT is 165 °C), according to the set compounding ratio (30:70), they are respectively fed into the twin-screw extruder for melt extrusion, and the melts of the two components respectively use two sets of metering pumps to enter the composite spinning through the melt pipe. The components are sprayed out from the spinneret, then cooled by the surrounding air, oiled, wound, and dropped into the barrel to obtain POY yarns, and finally deformed by the first hot box, false twister, shaped by the second hot box, and oiled and wound. Part o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com