Amorphous copolyester and application thereof

A copolyester and amorphous technology, applied in the field of amorphous copolyester and its application, can solve the problems affecting mechanical and processing properties, brittleness, etc., and achieve the effect of preventing the glass transition temperature from falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

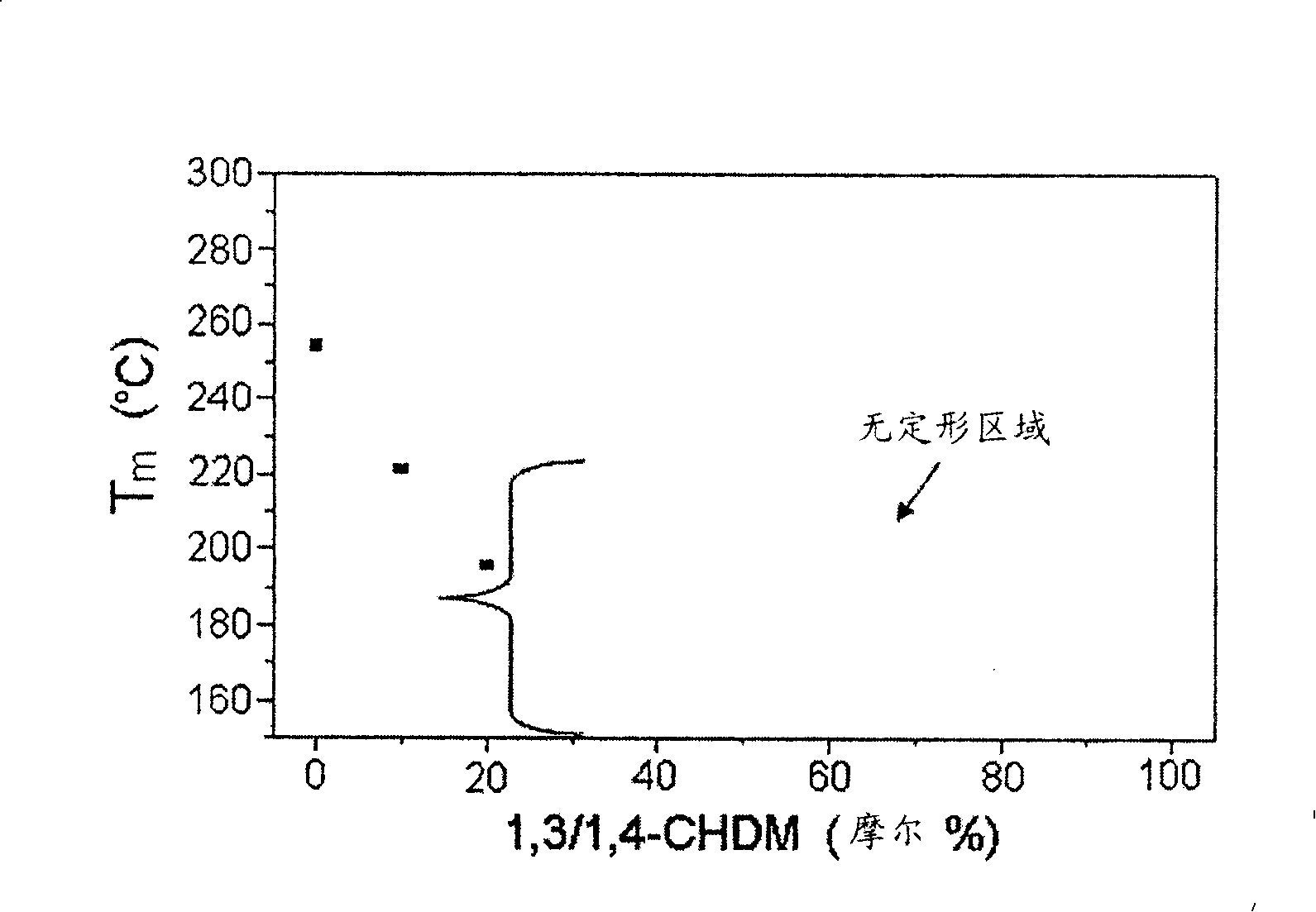

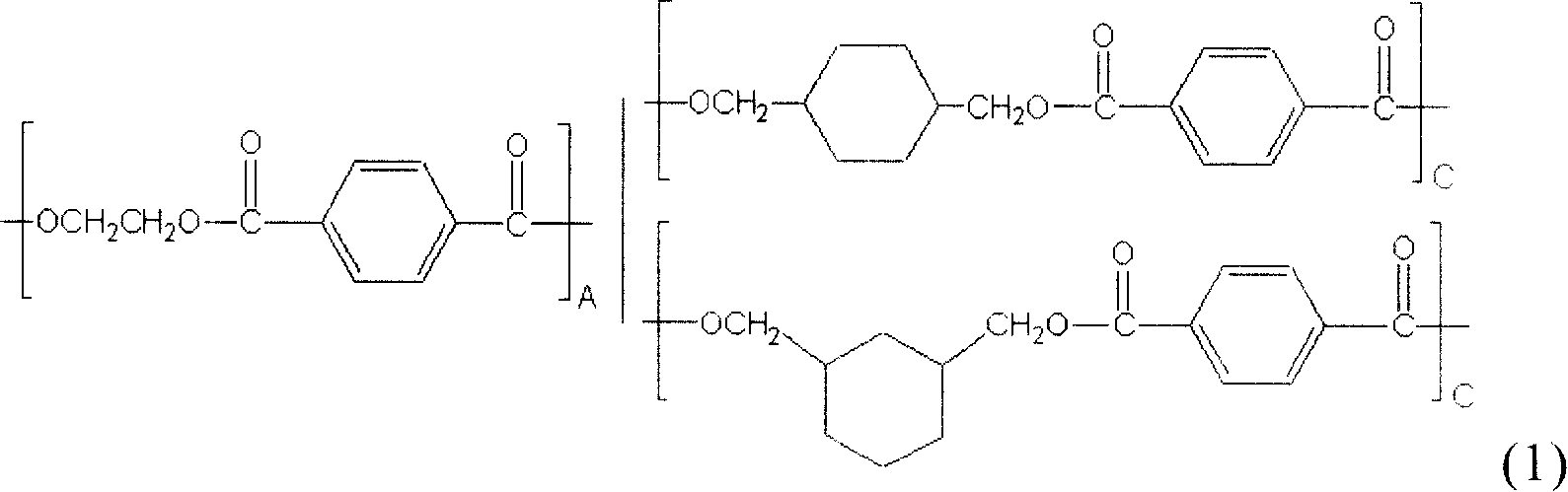

[0024] The amorphous copolyester of the first embodiment is synthesized by a kind of diacid monomer and two kinds of diol monomers, and its structural formula is as shown in formula (1):

[0025]

[0026] Among them, the diacid monomer includes terephthalic acid (abbreviated as TPA), and the diol monomer includes ethylene glycol (abbreviated as EG) and 1,3 / 1,4-cyclohexanedi Methanol (1,3 / 1,4-cyclohexanedimethanol, abbreviated as 1,3 / 1,4-CHDM), wherein the amount of 1,3 / 1,4-cyclohexanedimethanol added is 20 to 100 equivalents of diol mole %. In addition, the above-mentioned diacid monomers and diol monomers generally need to be synthesized through two-stage esterification and polycondensation, and a polycondensation catalyst needs to be added during the reaction process, and the content thereof varies from about 25 to 500 ppm. The polycondensation catalyst used here is, for example, one or more metal catalysts selected from antimony series, titanium series, germanium series...

no. 2 example

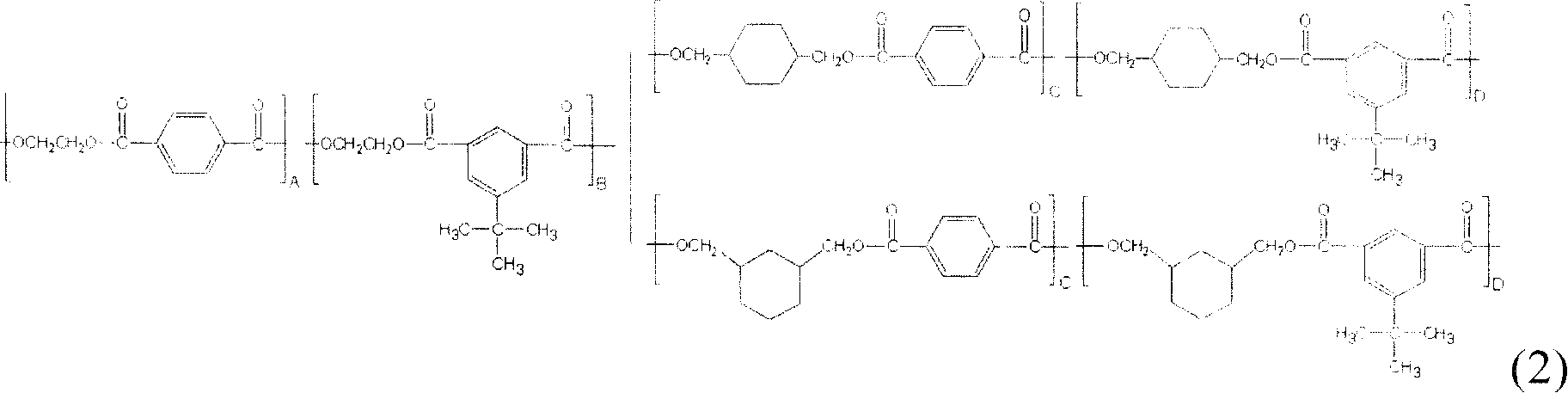

[0041] The amorphous copolyester of the second embodiment is synthesized by two kinds of diacid monomers and two kinds of diol monomers, and its structural formula is as shown in formula (2):

[0042]

[0043]Among them, diacid monomers include terephthalic acid (TPA) and 5-tert-butylisophthalic acid (5tBIA), diol monomers include ethylene glycol (EG) and 1,3 / 1,4-cyclohexane Alkanedimethanol (1,3 / 1,4-CHDM), wherein the addition of 5tBIA in diacid equivalent and the addition of 1,3 / 1,4-cyclohexanedimethanol in diol equivalent It is 20-100 mol%, and if the above-mentioned diacid monomer and diol monomer are synthesized through two-stage esterification and polycondensation, a polycondensation catalyst needs to be added during the reaction process, and its content is about 25-500ppm. The polycondensation catalyst used here is, for example, one or more metal catalysts selected from antimony series, titanium series, germanium series, tin series, gallium series, aluminum series an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com