Martensitic antibiotic stainless steel and thermal treatment method thereof

An antibacterial stainless steel and martensitic technology, applied in the field of martensitic stainless steel, can solve the problems of rapid antibacterial performance, durability, broad-spectrum antibacterial performance, disappearance, and decline in antibacterial rate, and achieve rapid antibacterial durability, The effect of reducing the action time and not reducing the antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The chemical composition is Cu: 1.34% by weight, C: 0.12% by weight, Si: 1.40% by weight, Mn: 0.44% by weight, Cr: 12.4% by weight, Ni: 0.15% by weight, Nb: 0.85% by weight, Mo: 2.45% by weight %, Ti: 0.65% by weight, and the balance is iron. After smelting and forging, the stainless steel is hot-rolled and then annealed, and then cold-rolled and annealed. Then keep it in solid solution at 1050°C for 0.5-1 hour, oil-cool or air-cool to room temperature, so that the copper can be evenly distributed in the stainless steel. Then aging at 500-800°C for 6 hours, air-cooling to room temperature, the ε-Cu phase can be uniformly dispersed and precipitated in the matrix.

[0028] The ε~Cu phase dispersed and precipitated during the aging process is the key to the bactericidal effect of martensitic antibacterial stainless steel, but at this time the matrix structure is tempered structure, and the strength and hardness are far from the performance requirements of martensitic stain...

Embodiment 2

[0062] The chemical composition is Cu: 2.05% by weight, C: 0.19% by weight, Si: 0.51% by weight, Mn: 1.38% by weight, Cr: 13.0% by weight, Ni: 0.16% by weight, Nb: 0.98% by weight, V: 0.94% by weight %, Zr: 0.46% by weight, and the balance is iron. After smelting and forging, the stainless steel is hot-rolled and then annealed, and then cold-rolled and annealed. Then heat it at 1050°C for 0.5 to 1 hour for solid solution, and cool it in oil or air to room temperature. Aging at 500-800°C for 6 hours, air cooling to room temperature. The martensitic stainless steel plate that has undergone solid solution and aging is kept at 950-1100°C for 3-30 minutes, then oil-cooled, and then kept at 550-650°C for 2 hours.

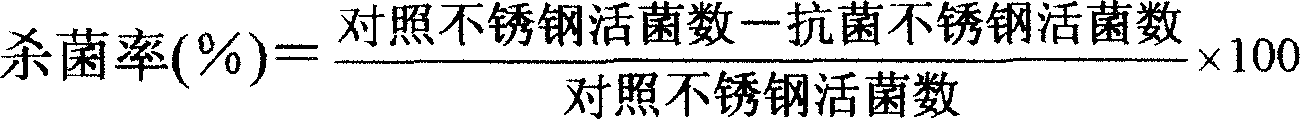

[0063] 1. Antibacterial experiment

[0064] In this experiment, ordinary 3Cr13 stainless steel was used as the control steel. Concrete experiment is with embodiment 1.

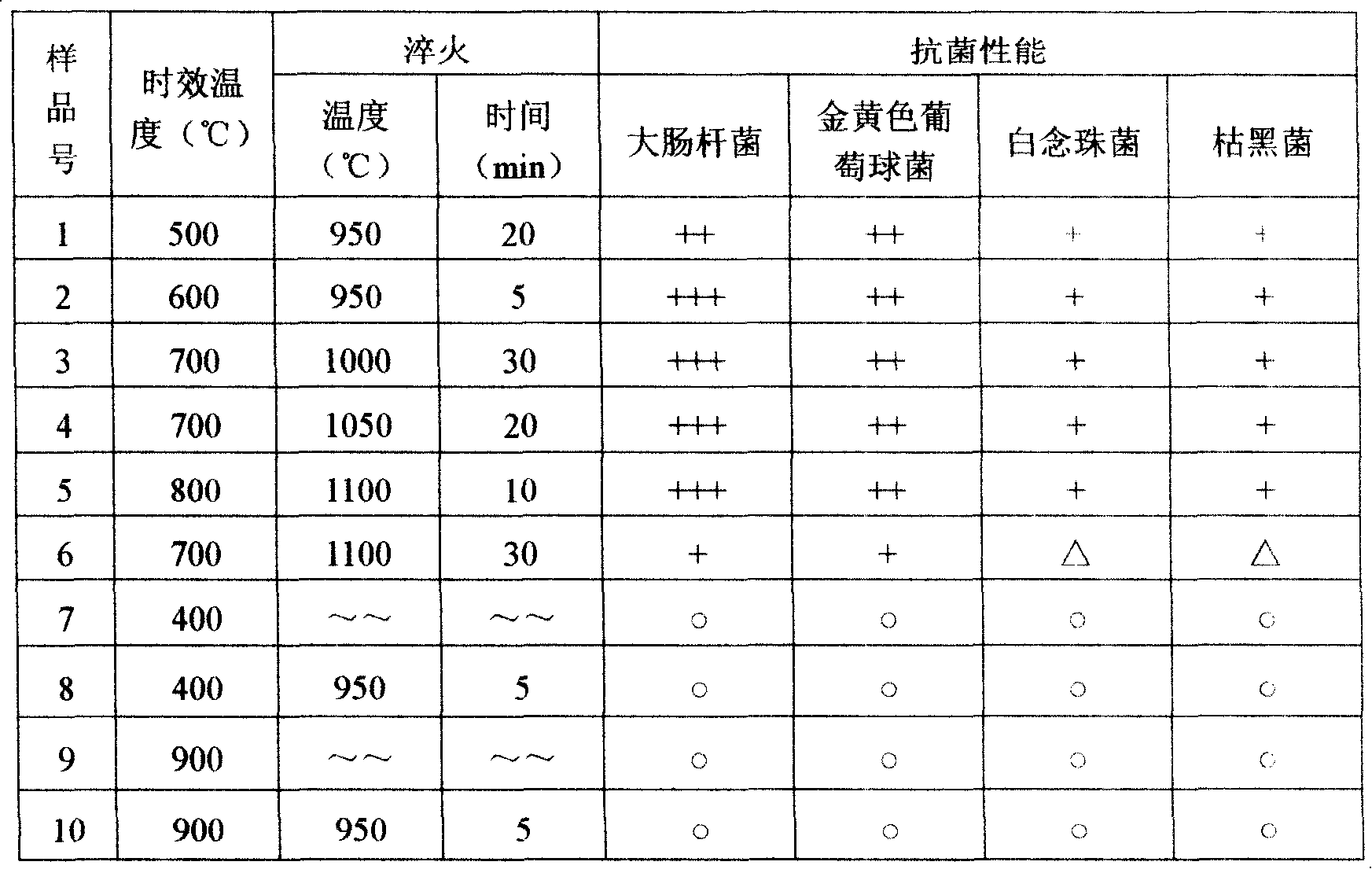

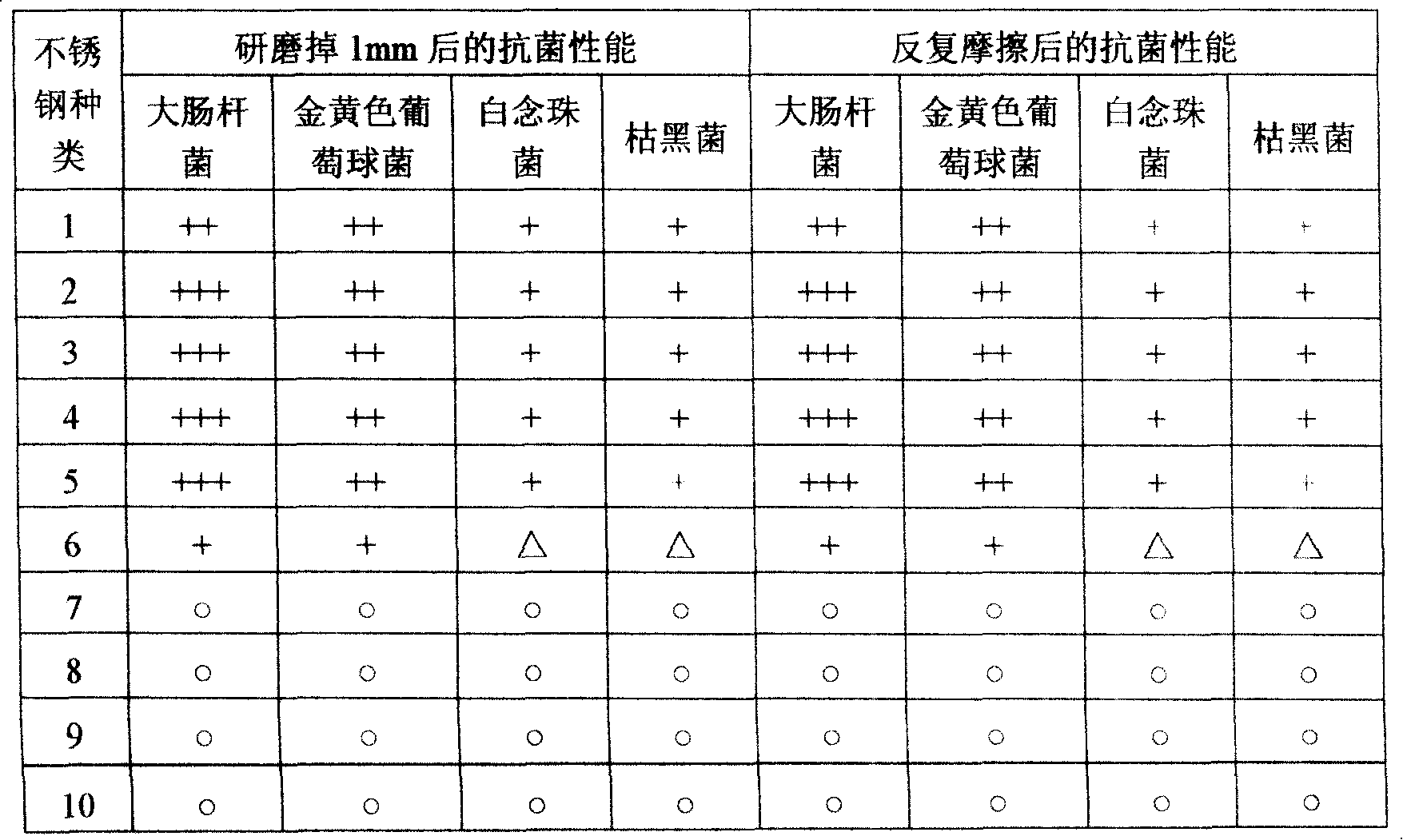

[0065] Table 4 Broad-spectrum antibacterial performance of martensitic antibacterial stainless ste...

Embodiment 3

[0078] The chemical composition is Cu: 3.13% by weight, C: 0.29% by weight, Si: 0.68% by weight, Mn: 0.28% by weight, Cr: 13.2% by weight, Ni: 0.14% by weight, Nb: 0.83% by weight, and the balance is iron After the stainless steel is smelted and forged, it is hot rolled and then annealed, and then cold rolled and annealed. Then heat it at 1050°C for 0.5 to 1 hour for solid solution, and cool it in oil or air to room temperature. Then aged at 500-800°C for 6 hours, and air-cooled to room temperature. The martensitic stainless steel plate that has undergone solid solution and aging is kept at 950-1100°C for 3-30 minutes, then oil-cooled, and then kept at 200-300°C for 2 hours.

[0079] 1. Antibacterial experiment:

[0080] In this experiment, ordinary 3Cr13 stainless steel was used as the control steel. Concrete experiment is with embodiment 1.

[0081] Table 7 Broad-spectrum antibacterial performance of martensitic antibacterial stainless steel

[0082]

[0083] 2. Anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com