Method of preparing sheet silver tin oxide electrical contact material

A technology of electric contact material, silver tin oxide, which is applied in the direction of contacts, circuits, electric switches, etc., to achieve the effect of short production cycle, low production cost and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

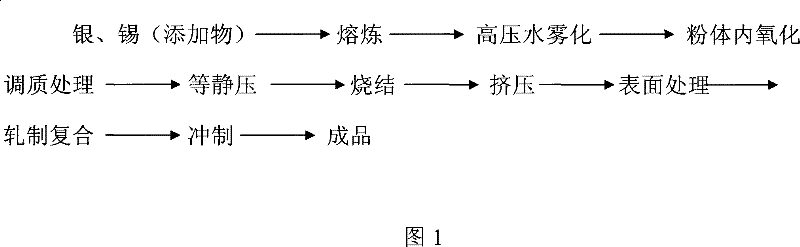

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one: by 98% silver (percentage by weight), 2% tin (percentage by weight) as raw material, water atomization under 30MPa pressure condition, in the air through 12 hours internal oxidation tempering treatment, at 250MPa etc. Pressed into ingots under static pressure, sintered at 780°C for 8 hours, and then extruded into plates at a temperature of 750°C. After surface treatment and silver coating, the plates were rolled, punched, and processed into sheets. contacts.

Embodiment 2

[0030] Embodiment two: by 90% silver (percentage by weight), 9.7% tin (percentage by weight) as raw material, and add 0.3% bismuth, water atomization under 39MPa pressure condition, in the air through 8 hours internal oxidation adjustment Quality treatment, pressed into an ingot under an isostatic pressure of 260MPa, sintered at 800°C for 8 hours, and then extruded into a plate at a temperature of 780°C, the plate was surface treated with silver, rolled and punched Molded, processed into sheet contacts.

Embodiment 3

[0031] Embodiment three: by 90% silver (percentage by weight), 9.5% tin (percentage by weight) as raw material, and add 0.3% bismuth, 0.2% zinc, water atomization under 35MPa pressure condition, in air After 12 hours of internal oxidation and tempering treatment, it is pressed into an ingot under an isostatic pressure of 250MPa, sintered at 780°C for 8 hours, and then extruded into a plate at a temperature of 750°C, and the plate is surface treated with silver. After that, it is rolled, punched and formed, and processed into sheet contacts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com