Nitrogen-containing compound luminescent material, manufacturing method and illuminating device used thereof

A technology of fluorescent materials and nitrogen compounds, applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of high manufacturing cost and low luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

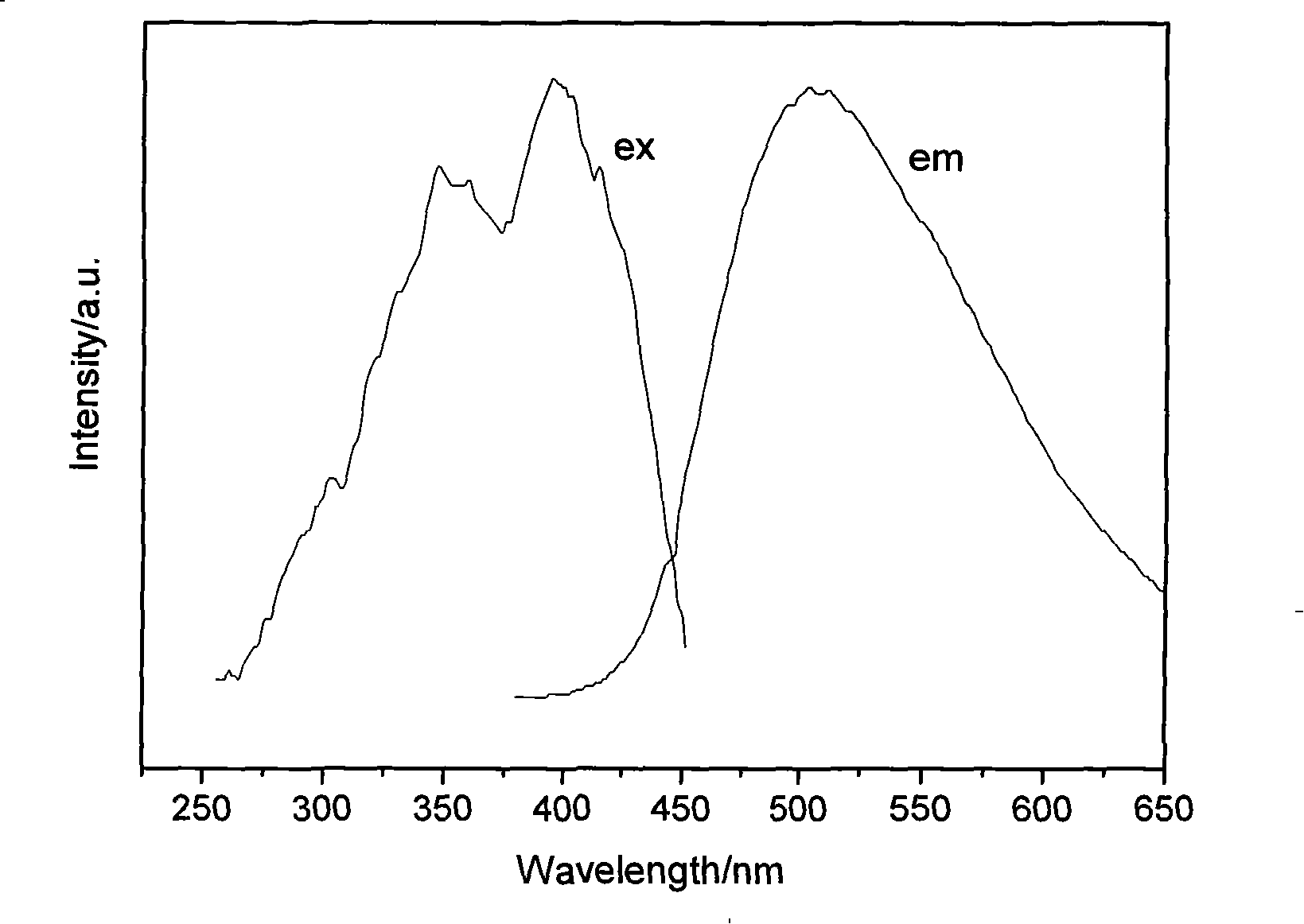

Embodiment 1

[0062] raw material

[0063] First, metal elemental Y and Ce are treated in flowing nitrogen at a temperature of 500 ° C to 1000 ° C to obtain Sr 3 N 2 and CeN precursor nitride components, followed by liquid SiCl in organic solvents 4 Reaction with ammonia gas, the filtered reaction product is subjected to reduction treatment between 300°C and 800°C to obtain active Si(NH) 2 components. Then, after weighing the above-mentioned components according to a certain molar ratio, they are fully ground and mixed uniformly. The above steps were all carried out under the protection of inert gas. Finally, put the mixture into a crucible, put it in an electric furnace, and 2 atmosphere (supplemented with a small amount of H 2 ) was calcined at 1200°C to 1600°C for 12 hours. After the sintered body is cooled, crush and grind, and then sieve with a 325-mesh sieve to obtain the fluorescent material Y with yellow-green luminescence in the present invention 2 Si 3 N 6 : Ce ...

Embodiment 2-8

[0064] Embodiment 2-8, preparation method and steps are the same as embodiment 1. The fluorescent materials of Examples 2-8 with yellow-green or yellow luminous colors were prepared by using the preparation method and steps for preparing the fluorescent material of Example 1. Table 1 shows the composition and luminous color of the fluorescent materials of each embodiment.

[0065] Table 1

[0066] Example

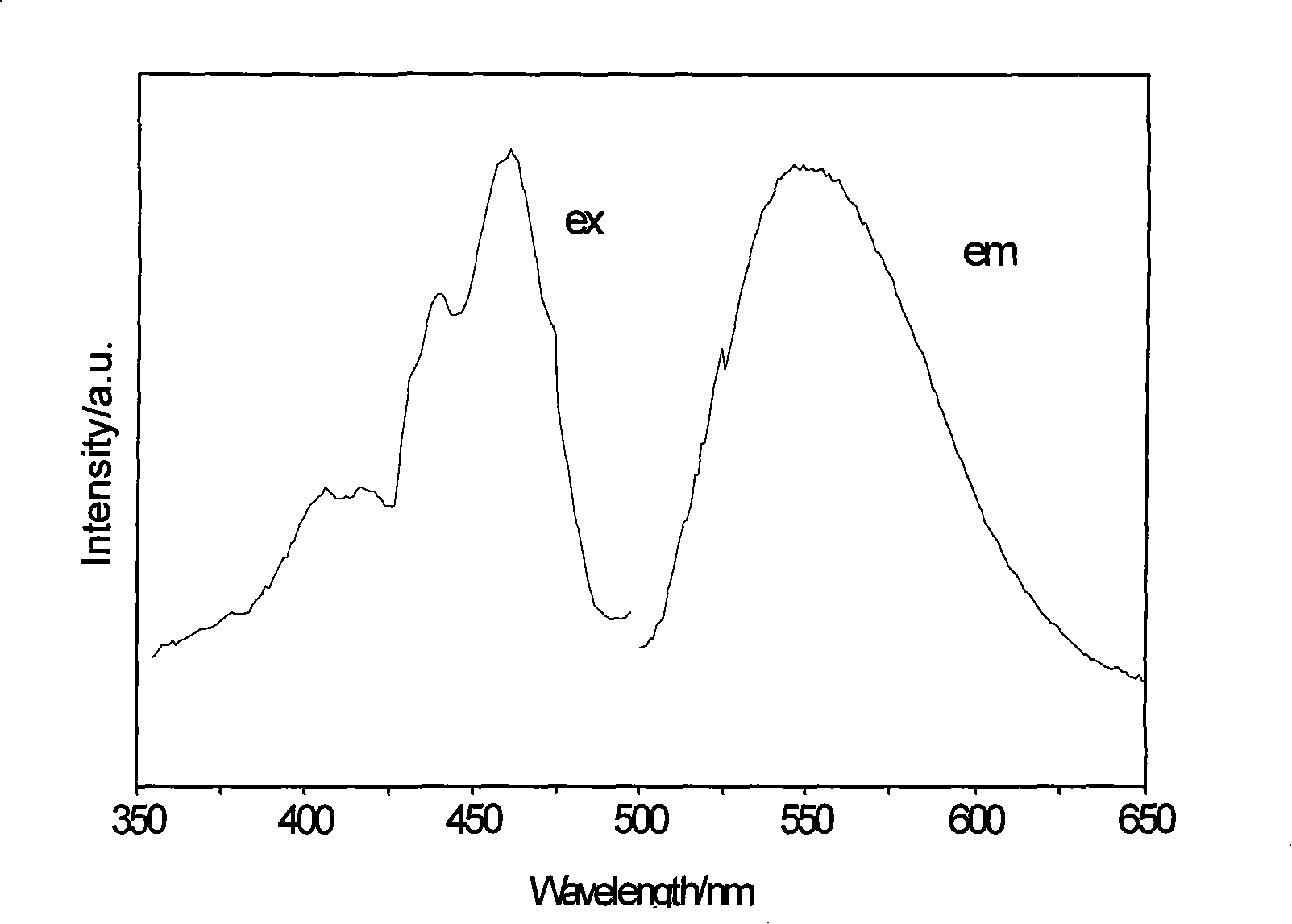

[0067] Example 7

Embodiment 9

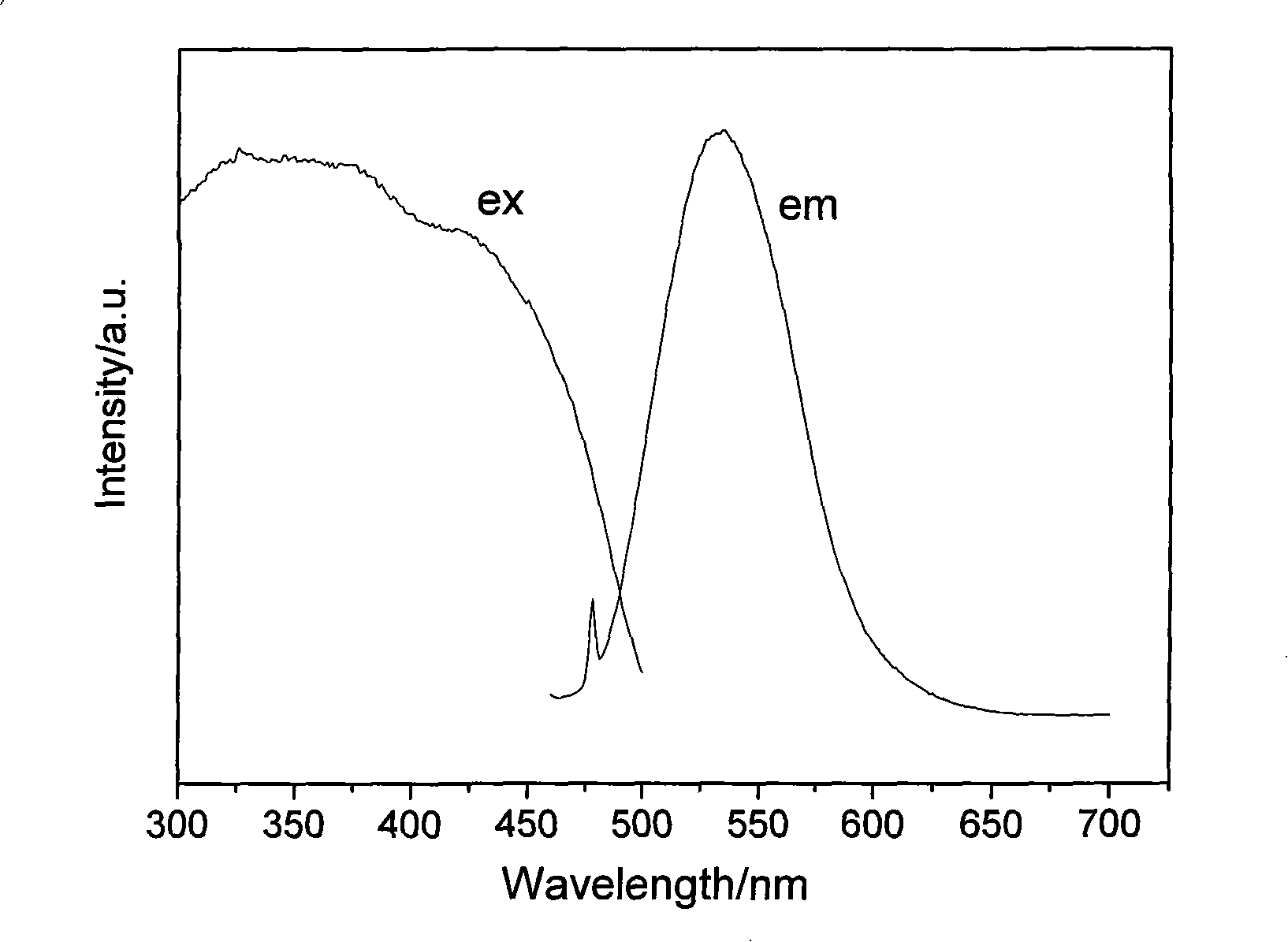

[0069] Firstly, metal elemental Ge and Eu are treated in flowing nitrogen at a temperature of 500 ° C to 1000 ° C to obtain Ge 3 N 2 and EuN precursor nitride components, followed by Ge 3 N 2 and EuN precursor nitride components and Ca 3 N 2 After weighing according to a certain molar ratio, fully grind and mix evenly. The above steps are carried out under the protection of inert gas. Finally, put the mixture into a crucible, put it in an electric furnace, and 2 atmosphere (supplemented with a small amount of H 2 ) was calcined at 1300°C to 1600°C for 10 hours. After the sintered body is cooled, it is pulverized and ground, and then sieved with a 325-mesh sieve to obtain the fluorescent material Ca with red light emission in the present invention. 2 GeN 2 :Eu 2 + . The excitation spectrum of the material is in the range of 300-550nm, the position of the main excitation peak is at 532nm; the position of the main emission peak is at about 625nm.

[0070] ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com