Multiple film series film coated glass and preparing method thereof

A technology of coated glass and film system, applied in the field of multi-film coated glass and automobile windshield, can solve the problems of visible light transmittance, insufficient infrared blocking force, etc., and achieve constant current, good conductivity and high transparency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

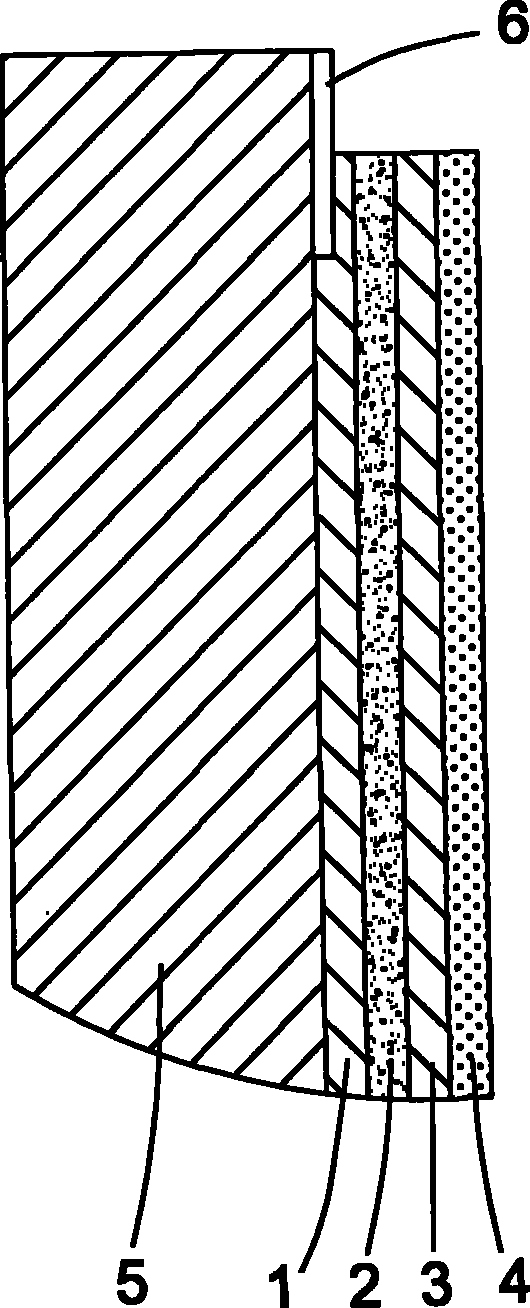

[0051] The invention is a method for preparing multi-film coated glass, comprising the following steps:

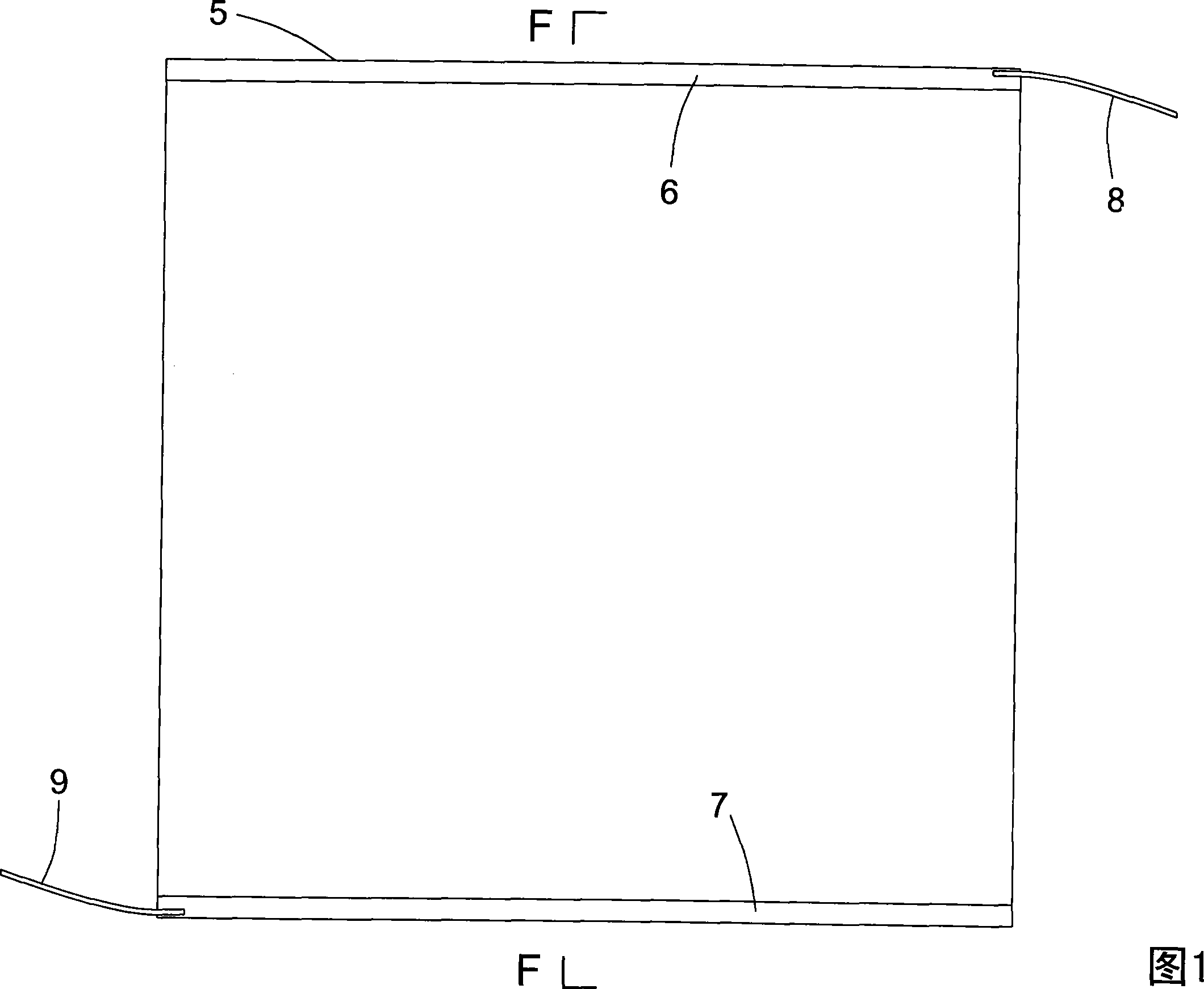

[0052] Step 1: Select float glass and cut it into glass pieces; the dimensions of the glass pieces are: length 400mm, width 400mm, thickness 2mm.

[0053]Step 2: Clean the glass sheet with a cleaning solution to remove surface oil, fingerprints and other dirt, then scrub with clean water and deionized water, and then heat and dry in an oven to remove moisture on the surface of the glass sheet.

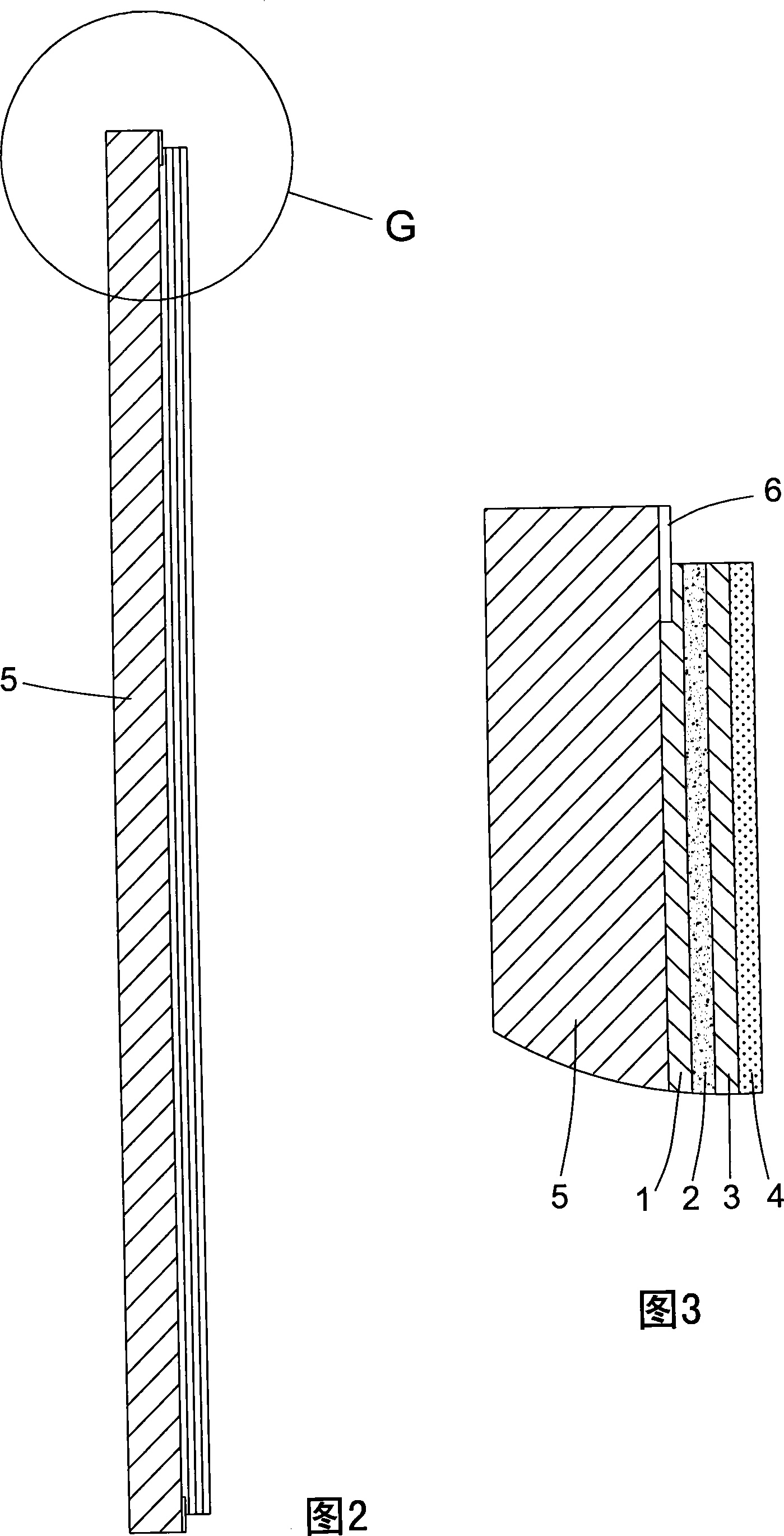

[0054] Step 3: Coating an indium tin oxide alloy film with a thickness of 28 nm on the surface of the glass sheet with a magnetron sputtering coating machine;

[0055] Step 4: On the surface of the above-mentioned indium tin oxide alloy film with a vacuum coating machine, a transition film with a thickness of 15nm is plated; the transition film is a ZnS film, a TiO 2 one of the membranes;

[0056] Step 5: plating an Ag film with a thickness of 22nm on the surface of the above-men...

Embodiment 2

[0059] The invention is a method for preparing multi-film coated glass, comprising the following steps:

[0060] Step 1: Select float glass and cut it into glass pieces; the dimensions of the glass pieces are: length 420mm, width 420mm, thickness 2.2mm.

[0061] Step 2: Clean the glass sheet with a cleaning solution to remove surface oil, fingerprints and other dirt, then scrub with clean water and deionized water, and then heat and dry in an oven to remove moisture on the surface of the glass sheet.

[0062] Step 3: Use a screen printing machine to print silver paste conductive glue on the upper and lower edges of the glass sheet to form two conductive strips; the width of each conductive strip is 10mm.

[0063] Step 4: Coating an indium tin oxide alloy film with a thickness of 32 nm on the surface of the above-mentioned glass sheet printed with conductive strips by using a magnetron sputtering coating machine.

[0064] Step 5: on the surface of the above-mentioned indium ti...

Embodiment 3

[0068] The invention is a method for preparing multi-film coated glass, comprising the following steps:

[0069] Step 1: Select float glass and cut it into glass pieces; the dimensions of the glass pieces are: length 440mm, width 440mm, thickness 2.4mm.

[0070] Step 2: Clean the glass sheet with a cleaning solution to remove surface oil, fingerprints and other dirt, then scrub with clean water and deionized water, and then heat and dry in an oven to remove moisture on the surface of the glass sheet.

[0071] Step 3: Use a screen printing machine to print silver paste conductive glue on the upper and lower edges of the glass sheet to form two conductive strips; the width of each conductive strip is 10mm.

[0072] Step 4: Coating an indium tin oxide alloy film with a thickness of 36 nm on the surface of the above-mentioned glass sheet printed with conductive strips by using a magnetron sputtering coating machine.

[0073] Step 5: on the surface of the above-mentioned indium ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com