High-strength toughness cold working die steel and method of producing the same

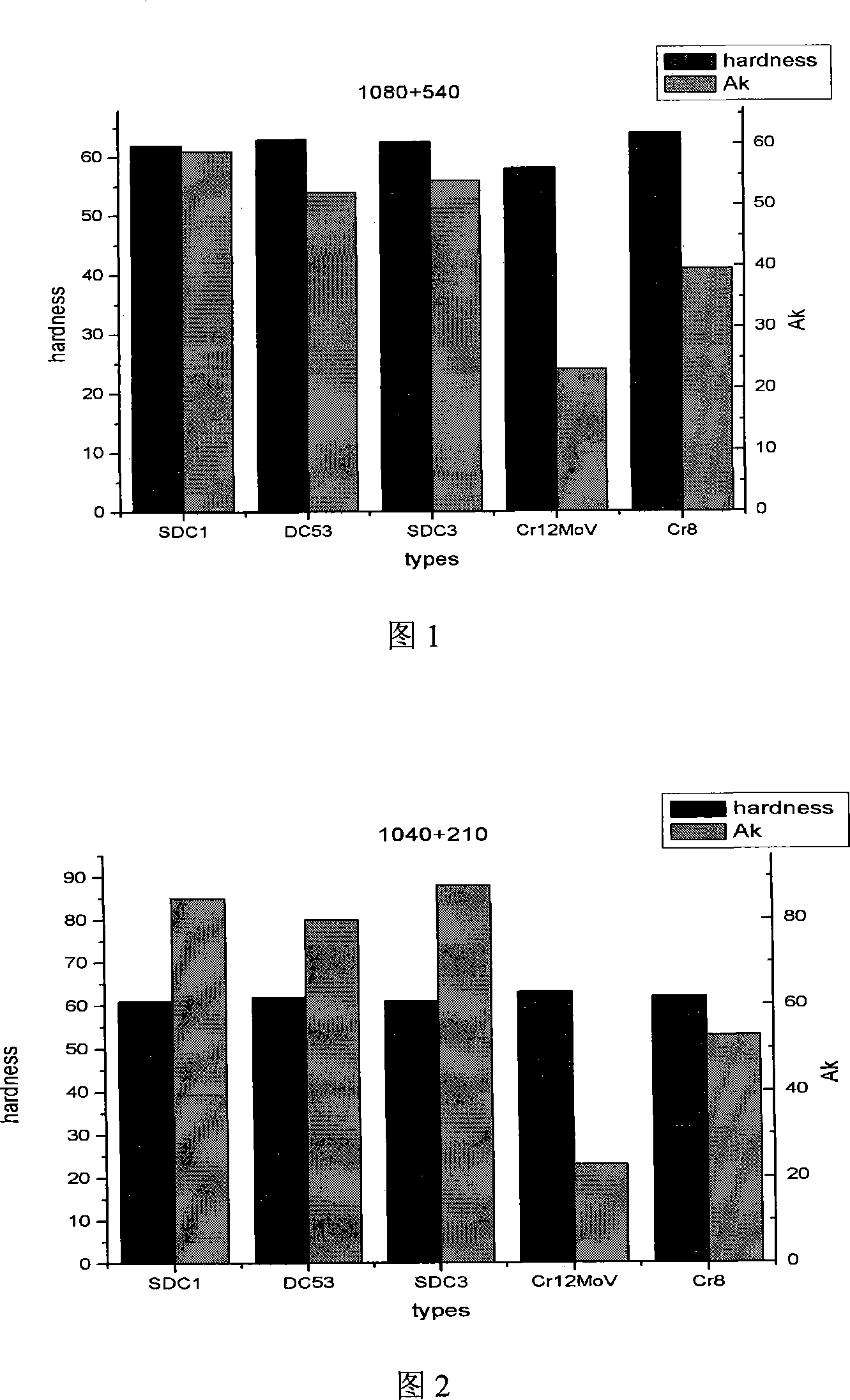

A cold work die steel, high-strength and toughness technology, applied in the field of alloy steel manufacturing process, can solve the problems of anisotropy of mechanical properties and physical properties, increased tendency of quenching crack formation, and poor grindability and abrasiveness. , to achieve the effect of improving macro and micro structure, hardness performance and impact resistance, and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: In the present embodiment, the chemical composition and weight percentage of alloy steel are as follows:

[0029] C 0.95%, Cr 9.5%, Mo 2.0%, V 1.0%, Si 1.0%, P<0.02%, S<0.02%, Fe balance.

[0030] The preparation process and steps of alloy steel in the present embodiment are as follows:

[0031] (a) Melting: After the alloy is designed according to the above composition, it is smelted according to the traditional conventional method. The alloy charge according to the above formula is placed in an intermediate frequency induction furnace or an electric arc furnace, and is smelted at a temperature above 1500°C, and then the steel ingot is poured into the next one step to use;

[0032] (b) Electroslag remelting: using electric current to generate resistance heat through the electroslag layer to melt the alloy steel base material of the consumable electrode, the liquid metal falls through the slag pool in the form of molten droplets into the metal molten pool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com