Million - kilowatts class nuclear power station reactor main bolt production process

A nuclear power plant reactor and manufacturing process technology, applied in the direction of reactors, manufacturing reactors, nuclear engineering, etc., can solve the problems that the tensile strength and impact value cannot meet the requirements at the same time, the scrapping of main bolt forgings in batches, and the mechanical performance requirements, etc., to meet the guarantee Comprehensive mechanical properties, guaranteed reliability and safety, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

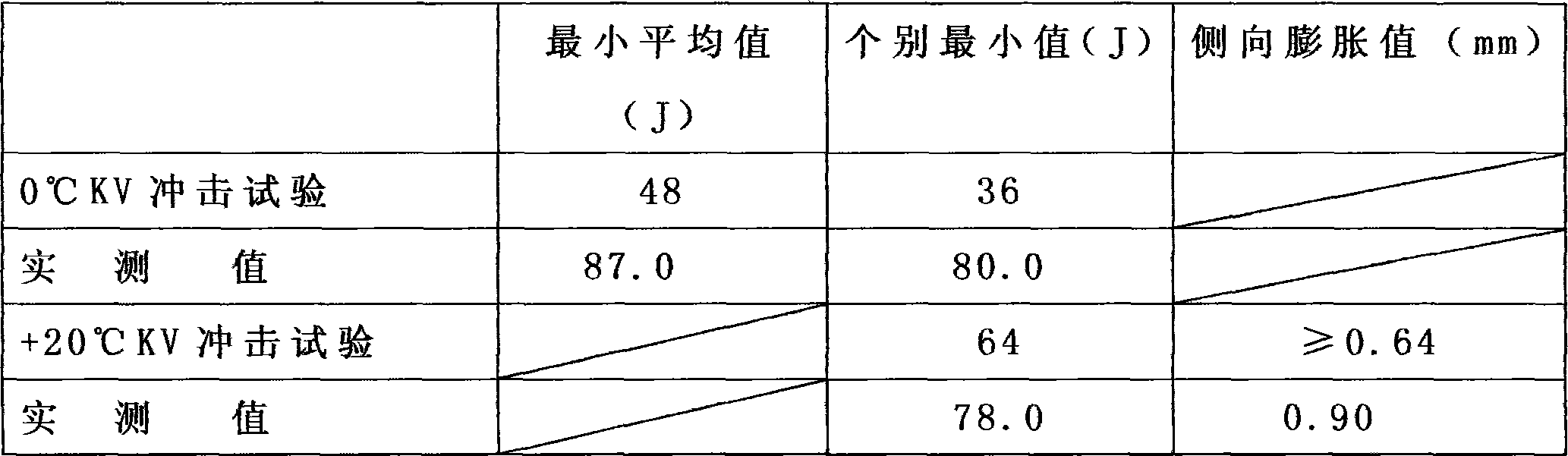

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment the present invention is described in further detail:

[0017] 1. Select the raw material 40NCDV7-03 for smelting, take samples from the ladle to test its trace element content and adjust it compared with the required value, and finally get the weight percentage content of each element as follows:

[0018] Chemical composition (wt% weight percent)

[0019]

C

mn

Si

P

S

Ni

Cr

Mo

Cu

V

want

beg

0.35

~

0.46

0.55

~

0.95

≤

0.35

≤

0.010

≤

0.010

1.55 ~

2.05

0.60~

1.00

0.35~

0.60

≤0.10

0.04

~

0.10

Reality

Measurement

0.40

0.71

0.19

0.009

0.009

1.77

0.76

0.47

0.07

0.06

[0020] Make sure it satisfies the required value;

[0021] 2. Heating of forging billet: When it reaches the middle temperature stage of 800-850°C, on the basis of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com