Minitype permanent magnetism synchronization gear wheel free traction machine

A technology of gear traction machine and permanent magnet synchronous motor, which is applied in the field of elevator traction machine and small permanent magnet synchronous gearless traction machine, can solve the problems of increased installation difficulty, complicated processing technology, and increased assembly difficulty, etc. To achieve the effect of easy installation and maintenance, improve safety performance and prolong working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable the examiners of the patent office and the public to further understand the technical essence and beneficial effects of the present invention, the applicant describes the following with specific but non-exclusive embodiments:

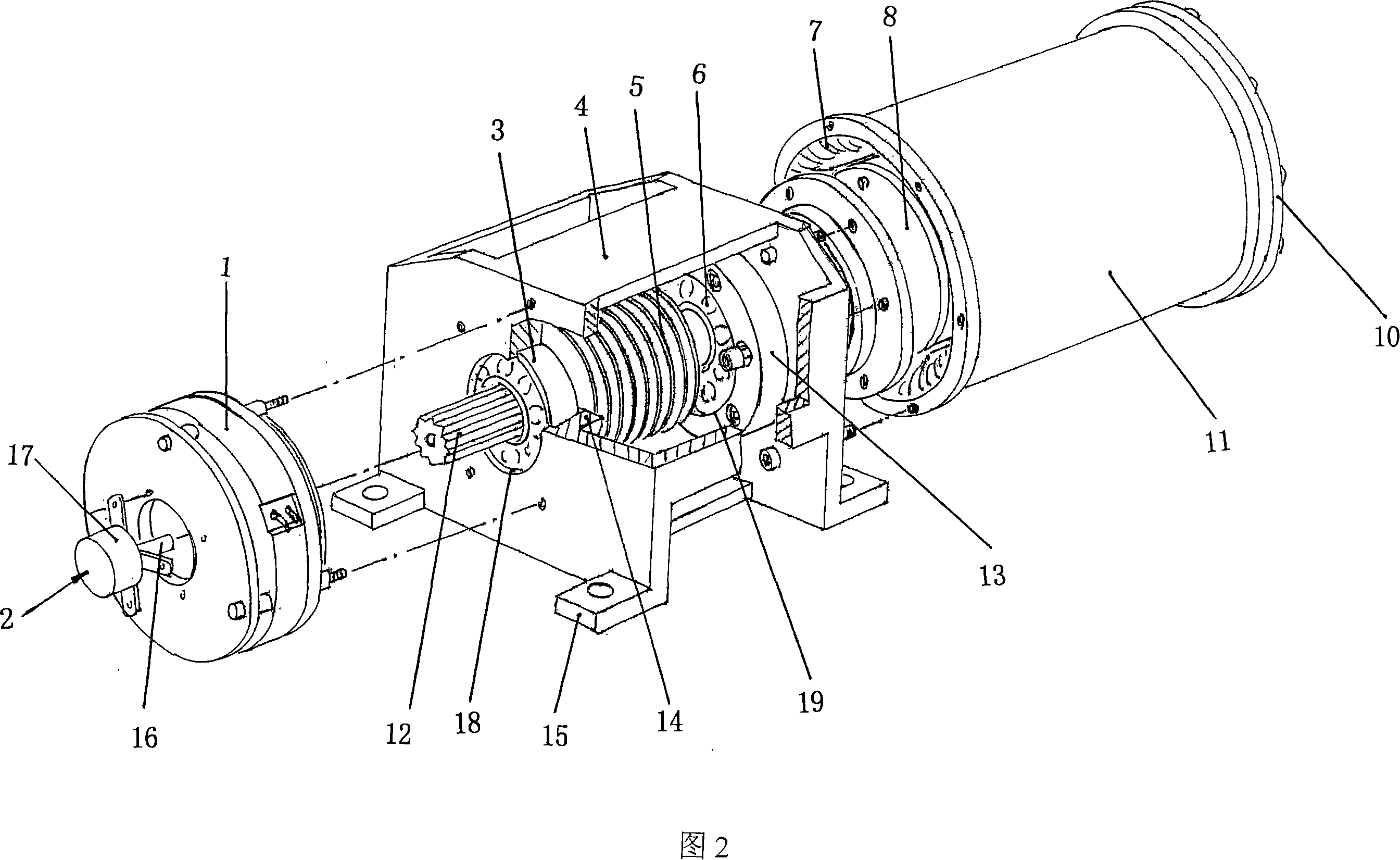

[0020] Please refer to Fig. 1 and in conjunction with Fig. 2, the permanent magnet synchronous motor provided by the present invention is an inner rotor permanent magnet synchronous motor structure, which mainly includes a rotor 8, a stator 7, a sleeve 11, a cylinder cover 10, and the rotor 8 is fixed on the main shaft 12 Above, the stator 7 is sleeved outside the rotor 8, and an air gap is formed between the outer surface of the rotor 8 and the inner surface of the stator 7, and the sleeve 11 is sleeved outside the stator 7. The screw is fixed, the sleeve 11 is fixed on the outside of the right end of the machine base 4 by bolts, and a cover 10 is sealed at the end of the sleeve 11 away from the machine base 4, and a third bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com