Mems device and fabrication method thereof

A manufacturing method and device technology, applied in the field of MEMS devices, can solve problems such as resistance value increase, mechanical strength decrease, and difficult resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

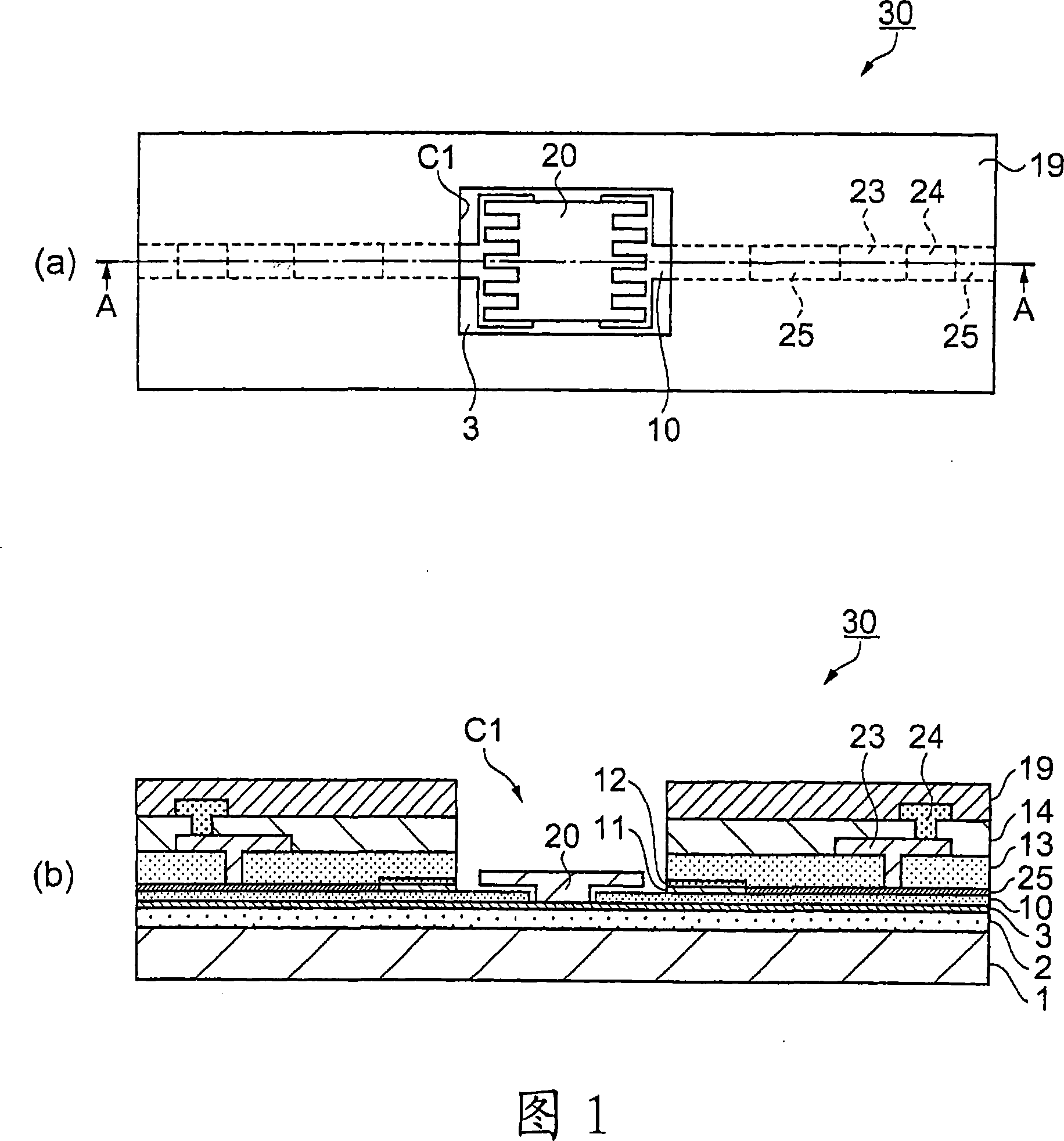

[0038] First, an embodiment of a MEMS device will be described with reference to the drawings. FIG. 1( a ) is a plan view showing the structure of a preferred embodiment of the MEMS device of the present invention, and FIG. 1( b ) is a cross-sectional view along line A-A in FIG. 1( a ).

[0039] MEMS device 30 shown in FIG. 1 has on silicon substrate 1: fixed electrode 10 provided in a fixed state; 13. The first wiring layer 23 , the second interlayer insulating film 14 , the second wiring layer 24 and the protective film 19 are formed. Furthermore, a movable electrode 20 provided in a movable state in an opening C1 serving as a space formed substantially in the center of the wiring laminated portion is provided. The surface of the portion of the fixed electrode 10 covered with the wiring lamination is converted into silicide, and a silicide portion 25 is formed.

[0040] On the silicon substrate 1, silicon oxide films (SiO 2 , for example, an insulating film 2 of a thermal...

no. 2 approach

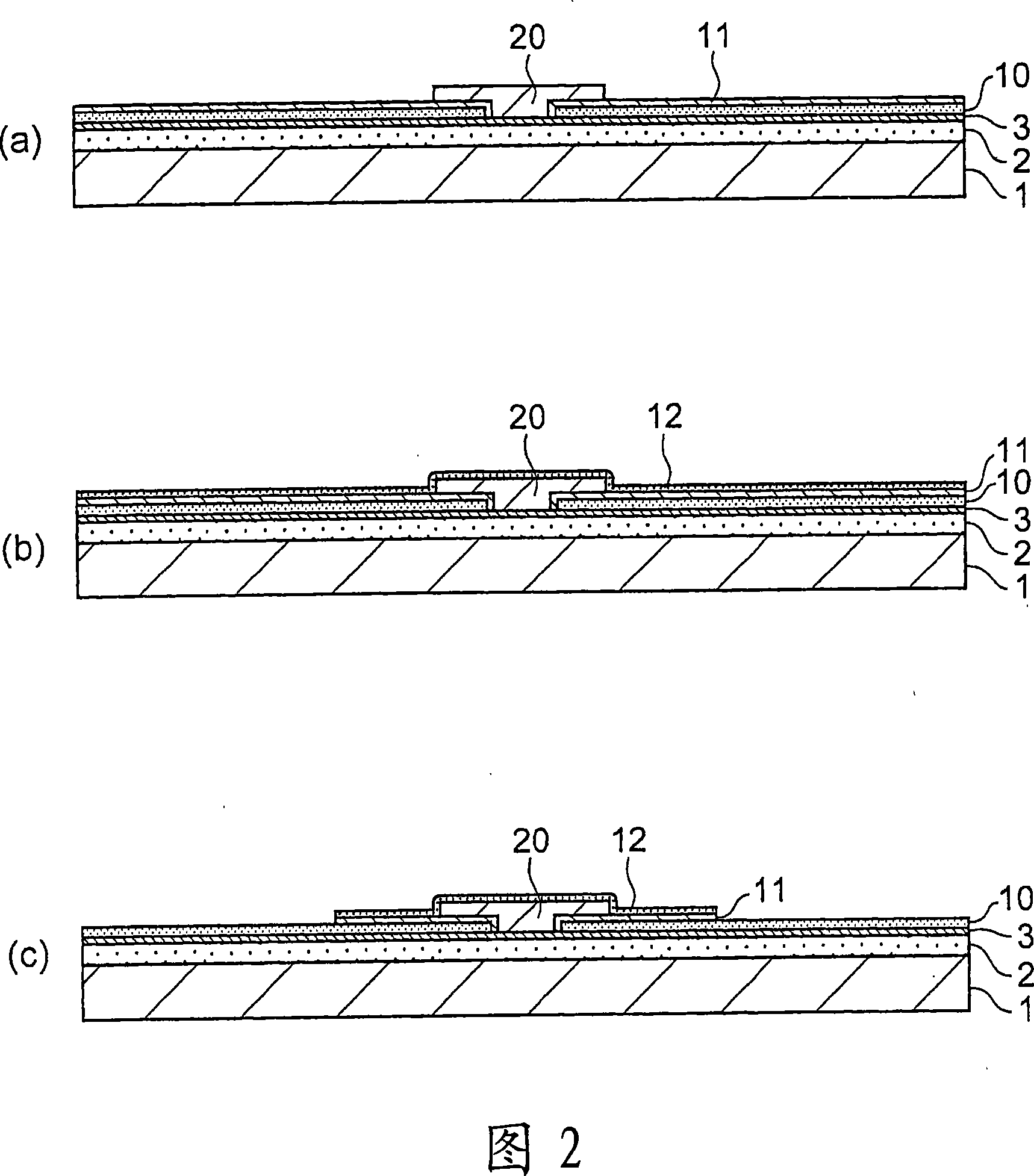

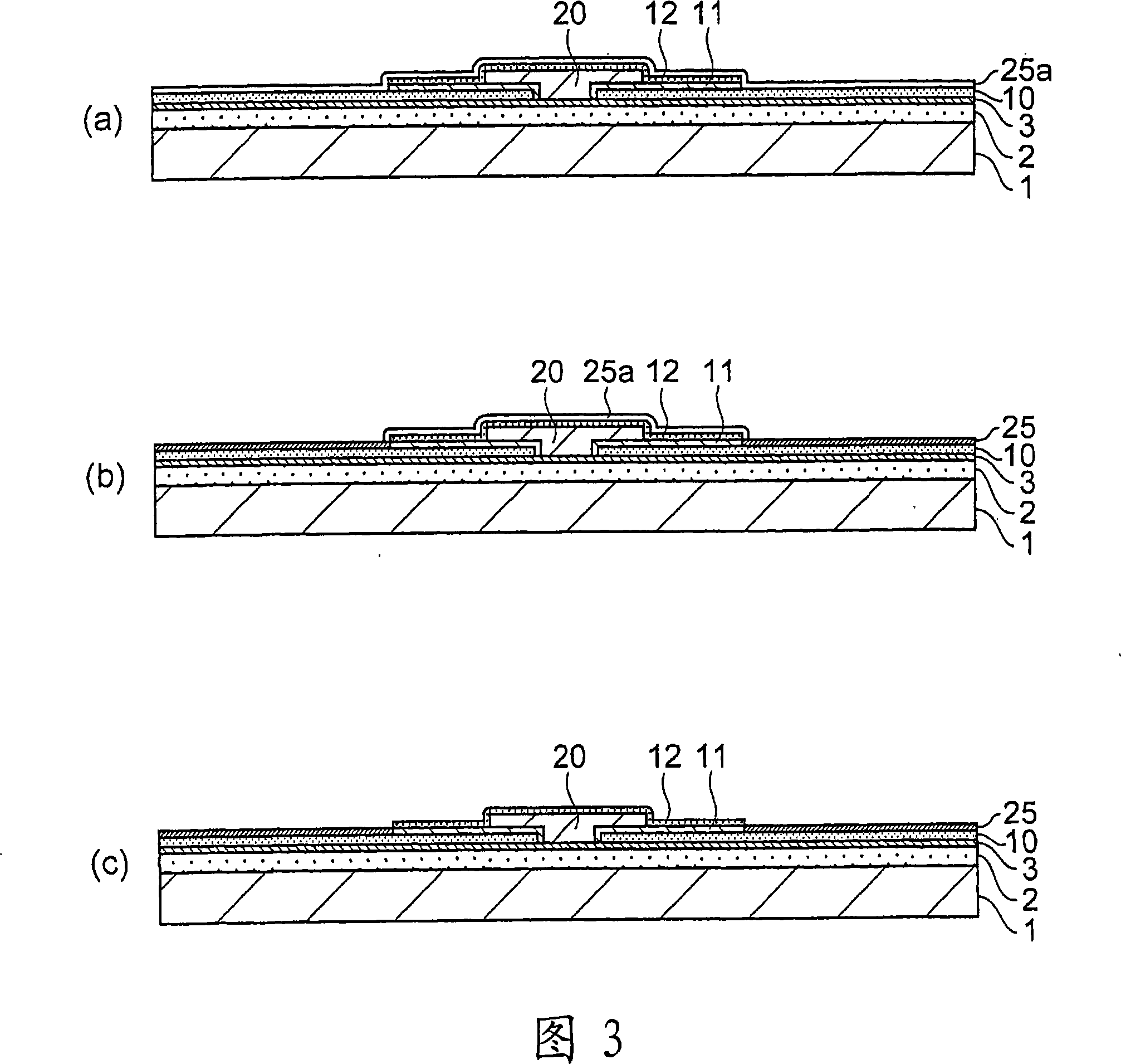

[0048] Next, a method of manufacturing the MEMS device 30 according to the first embodiment described above will be described. 2 , 3 , and 4 are schematic cross-sectional views illustrating the manufacturing process of the MEMS device 30 . 2, 3, and 4 illustrate the cross-section of the MEMS device 30 at the same position as that of FIG. 1(b).

[0049] In the fabrication of MEMS device 30, semiconductor fabrication processes are used. In FIG. 2(a), the surface of the silicon substrate 1 is thermally oxidized, etc., to form a silicon oxide film (SiO 2 ) and a nitride film 3 made of silicon nitride (SiN) or the like is deposited by CVD or sputtering. This nitride film 3 serves as a base layer functioning as an etching stopper layer when performing release etching described later.

[0050] Next, a polysilicon film is stacked on the nitride film 3 by CVD or the like, and phosphorus ions (for example, 31 P + ) and other impurity ions, the fixed electrode 10 is formed by patter...

no. 3 approach

[0066] Regarding the MEMS device 30 of the above-mentioned first embodiment manufactured by the manufacturing method of the above-mentioned second embodiment, the part of the fixed electrode 10 that is not exposed to the release of the etching solution when the movable electrode 20 is released is converted into a silicide, thereby Silicide portion 25 is formed. In contrast, in this third embodiment, an example in which a silicide portion is formed on a portion of a movable electrode and a fixed electrode exposed to a release etching solution will be described with reference to the drawings.

[0067] FIG. 5 is a schematic cross-sectional view illustrating a MEMS device 70 according to a third embodiment, and shows a cross-section at the same position as that in FIG. 1( b ) in the above-mentioned first embodiment. In addition, in the configuration of the MEMS device 70 of the third embodiment, the same configurations as those of the MEMS device 30 of the first embodiment are ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com