A relieving cough dropping pills and its preparing method

The technology of dripping pills and 100 parts is applied in the field of cough-relieving dripping pills and its preparation, which can solve the problems of slow dissolution and low utilization, and achieve the effects of fast dissolution, improved phagocytosis, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Here is an example of a preferred solution:

[0030] The matrix adopts polyethylene glycol 6000, and the weight ratio of the extract and the matrix is 1:1.

[0031] 1. Preparation of extract

[0032] (1) Take 9.2kg of herbal medicines, add 70% ethanol for reflux extraction twice, add 6 times the amount of ethanol for the first time, reflux extraction for 3 hours, add 4 times the amount of ethanol for the second time, reflux extraction for 2 hours, and combine ethanol extraction liquid, filtered, recovered ethanol, and water for later use.

[0033] (2) Take 9.2kg of Peucedanum herb, add water to decoct three times, add 10 times the amount of water for the first time, decoct for 3 hours, add 6 times the amount of water for the second time, decoct for 1 hour, and add 4 times the amount for the third time water, decocting for 0.5 hours. Combine the decoctions, filter, combine the filtrate with the water of Baibu, concentrate under reduced pressure to 2g crude drug / ml, ...

Embodiment 2

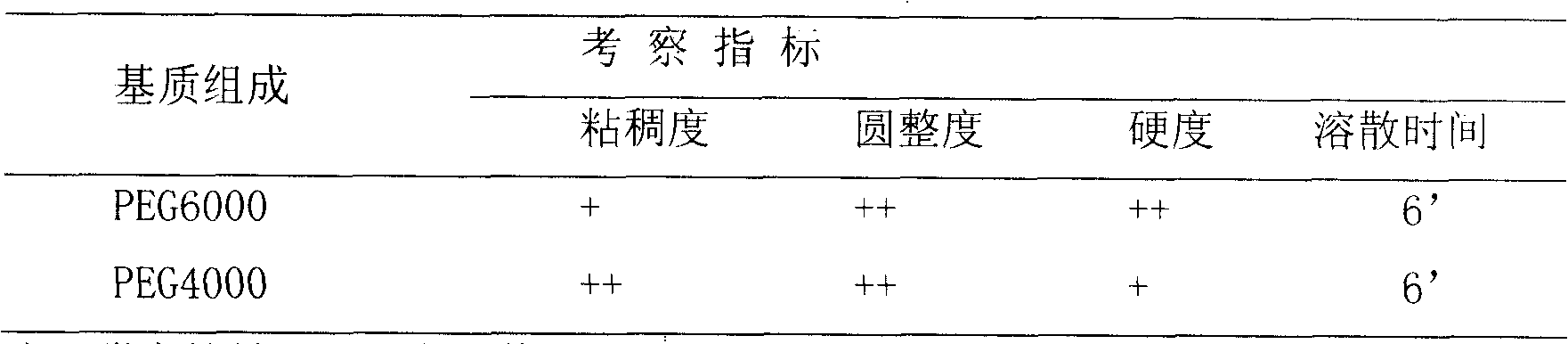

[0044] Choose different matrices to carry out the experiment of formulating.

[0045] Using polyethylene glycol 4000 as the base, mix the extract and the base evenly at a ratio of 1:1, and follow the steps specified in Example 1 for the rest, heat the prepared materials of each group until melting, and use the dripping pill Machine, adjust its temperature control system to meet the requirements of the sixth step of the preparation process in Example 1, use methyl silicone oil as a condensing agent, prepare according to the process given in Example 1, and use Polymerization in Example 1 For the comparison of ethylene glycol 6000 as the matrix, see the attached table 1 for the experimental results.

[0046] Table 1 Experiments of extracts mixed with different substrates

[0047]

[0048] Note: The symbol "-" in the attached table means slightly worse, "+" means average, and "++" means better.

Embodiment 3

[0050] Experiments with different ratios of extract and matrix.

[0051] In order to investigate the influence of the extract and the matrix in different ratios on the products involved in the present invention, the extract and the matrix are mixed evenly with the ratio of 1:0.5, 1:1, 1:3, and 1:5 respectively, and the matrix is selected. Polyethylene glycol 6000, and others are all according to the steps specified in Example 1. The prepared materials of each group are heated to melt respectively, and the temperature control system is adjusted to meet the sixth step of the preparation process in Example 1 by using a dropping pill machine. requirements, using methyl silicone oil as a condensing agent, and preparing according to the process given in Example 1, 4 recipe experiments with different ratios of extract and matrix were obtained, and 4 groups of different experimental results were obtained, see the attached table 2.

[0052] Table 2 Experiments with different ratios ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com