Data stream relating control method and architecture of computer digital control system

A digital control system and associated control technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of surface quality degradation, restriction of machining accuracy and feed speed, energy waste, etc., to reduce energy consumption and feed speed The effect of optimization and optimization of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

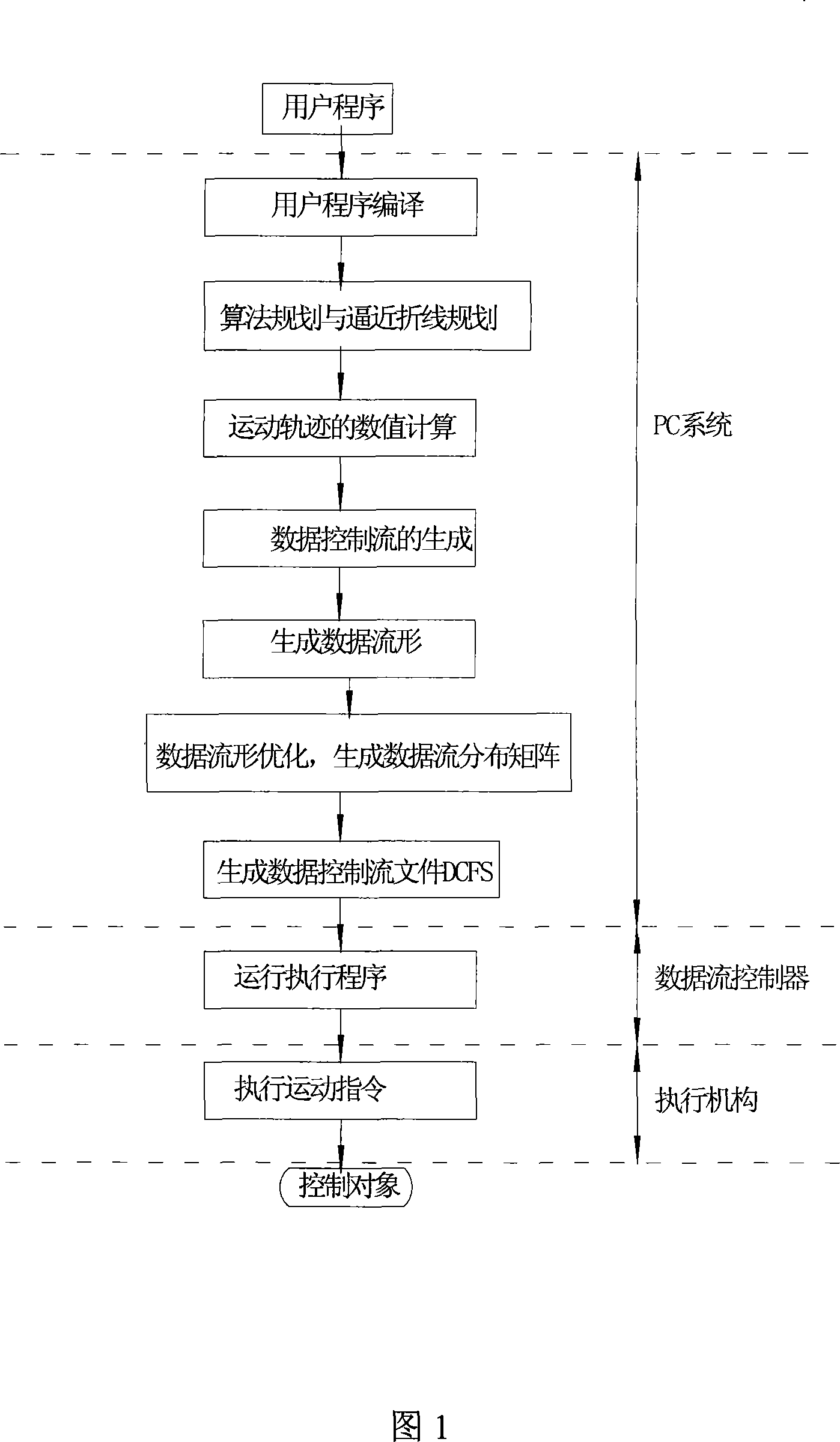

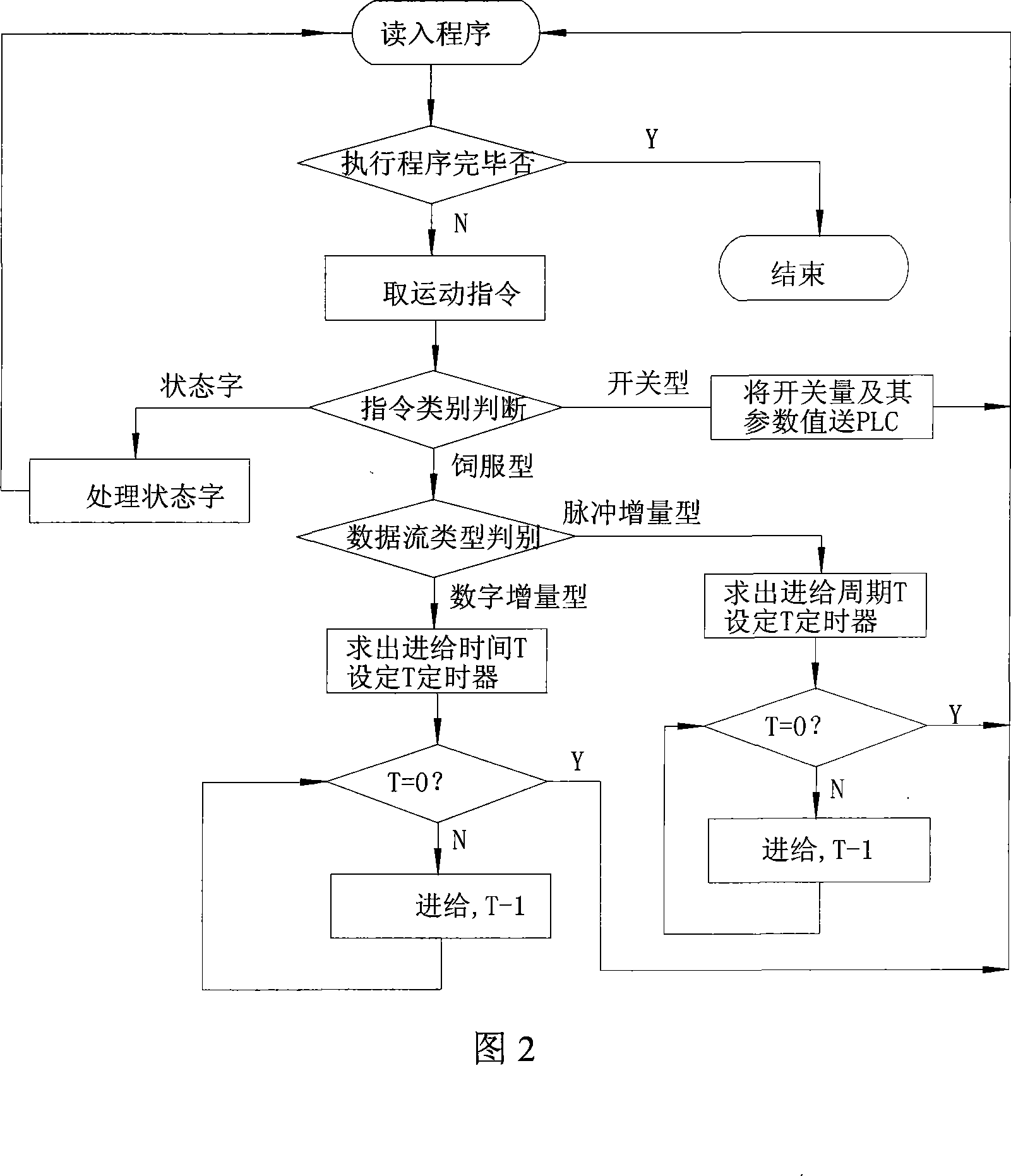

[0057] A kind of DRC control method applied to numerical control equipment as shown in Figure 1, comprises the following steps:

[0058] In the first step, the PC system reads in the user program and compiles the user program.

[0059] The user program is the control request sent by the user to the actuator, and the actuator is the control object of the numerical control system. The motion instructions in the user program are established based on the motion performance of the actuator. Therefore, the user program is oriented to the actuator and also to the user.

[0060] There are two types of actuators, one is to complete the trajectory movement according to the given rules, and this type of actuator is the feed servo system. Another type of actuator is a switching device, which activates a switch to output a given parameter value. For example, the X-axis feeds 50mm forward at a speed of 1m / s, and the water pump outputs coolant at a flow rate of 2L / s.

[0061] Generally, t...

specific Embodiment approach 2

[0171] As shown in Figure 6, the architecture of the numerical control system using the data flow correlation control technology includes a PC system 1, a data flow controller 2, and an actuator 3.

[0172] The PC system 1 includes a PC, a network card, and a system bus 7 . Its function is to calculate and process user information, input user information through PC or network card, and output and execute programs through system bus 7. There are two types of input of user information: input of user program through programming language and task file of flexible manufacturing system (FMS) input through network card.

[0173] The processing of user information adopts the data flow association control technology in the first embodiment to compile user programs, process data, generate data control flow, optimize data manifold, and generate data flow distribution matrix and DCFS files.

[0174] Among them, the data processing is mainly the numerical calculation of tool compensation ...

specific Embodiment approach 3

[0179]As shown in Figure 8, the architecture of the numerical control system adopting the data flow associated control technology includes a PC system 1, a data flow controller 2, and an actuator 3. It differs from the second embodiment in that: there are multiple sets of data flow controllers 2 and actuators 3 . The PC system 1 adopts the data flow association control technology in the first embodiment to process the user program and generate multiple DCFS files, which are respectively output to each data flow controller 1 and executed by each actuator 3 accordingly.

[0180] Since the data flow controller 1 is a numerical control system that takes DCFS files as input. In the DRC control method, the PC system generates the DCFS file of the user program offline without participating in real-time control. The powerful numerical calculation ability, information processing ability and real-time management ability of the PC system can be fully utilized, and it becomes a centralize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com