Anti-static polyphenylacetylene combination and preparation method and sheet material

A technology of polystyrene sheet and polystyrene, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high humidity dependence, surface deterioration, and lack of long-term effect, so as to improve packaging Grade, low humidity sensitivity, and the effect of improving advanced nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

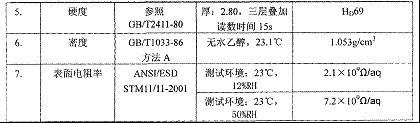

Examples

Embodiment 1

[0022] Polyethylene glycol monomethyl ether methacrylate PEDMA 1 7.4%, hydroxyethyl methacrylate HEMA4.96%, coupling agent KH-570 1.4%, azobisisobutyronitrile AIBN 0.12%, sodium perchlorate Na + 3.02%, HIPS polystyrene 73%, other 0.10% (others are mainly antioxidants, anti-aging agents, reinforcing agents, toughening agents).

[0023] Polyethylene glycol monomethyl ether PEDMA methacrylate, hydroxyethyl methacrylate HEMA, azobisisobutyronitrile AIBN, sodium perchlorate Na + The material is reacted at 60-90°C for 2-6 hours, then poured out, and baked at 45-100°C for several hours to obtain an antistatic material.

[0024] Mix the antistatic material obtained from the above reaction with polystyrene, antioxidant 1010, antioxidant 168, silane coupling agent KH-570, reinforcing agent and toughening agent, knead at 60°C for 43 minutes, and feed to extrusion The extruder is extruded, the speed of the feeder is 520 rpm, the temperature of the extrusion is 180 ° C ~ 210 ° C, the spe...

Embodiment 2

[0028] The formulation of antistatic plastic is as follows:

[0029] Polyethylene glycol monomethyl ether methacrylate PEDMA 16.04%, hydroxyethyl methacrylate HEMA 4.57%, coupling agent KH-570 1.4%, azobisisobutyronitrile AIBN 0.11%, sodium perchlorate Na + 2.78%, HIPS polystyrene 75%, other 0.10% (others are mainly antioxidants, anti-aging agents, reinforcing agents, toughening agents).

[0030] The preparation method of the polymer antistatic polystyrene plastic sheet is the same as in Example 1.

Embodiment 3

[0032] The formulation of antistatic plastic is as follows:

[0033] Polyethylene glycol monomethyl ether methacrylate PEDMA 18.76%, hydroxyethyl methacrylate HEMA 5.35%, coupling agent KH-570 1.4%, azobisisobutyronitrile AIBN 0.13%, sodium perchlorate Na + 3.26%, HIPS polystyrene 71%, other 0.10% (the other 0.10% is antioxidant, antiaging agent, reinforcing agent, toughening agent). The coupling agent is silane coupling agent KH-570 produced by Nanjing Shuguang Chemical General Factory, and the reinforcing agent and toughening agent are commonly used plastic reinforcing agents and toughening agents.

[0034] The preparation method of the polymer antistatic polystyrene plastic sheet is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com