Processing method of scrap blood and apparatus

A treatment equipment and treatment method technology, applied to waste disinfection or sterilization methods, chemistry, heating, etc., can solve the problems of staff infection, blood splashing, and affecting disinfection effects, so as to avoid infection and ensure health and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

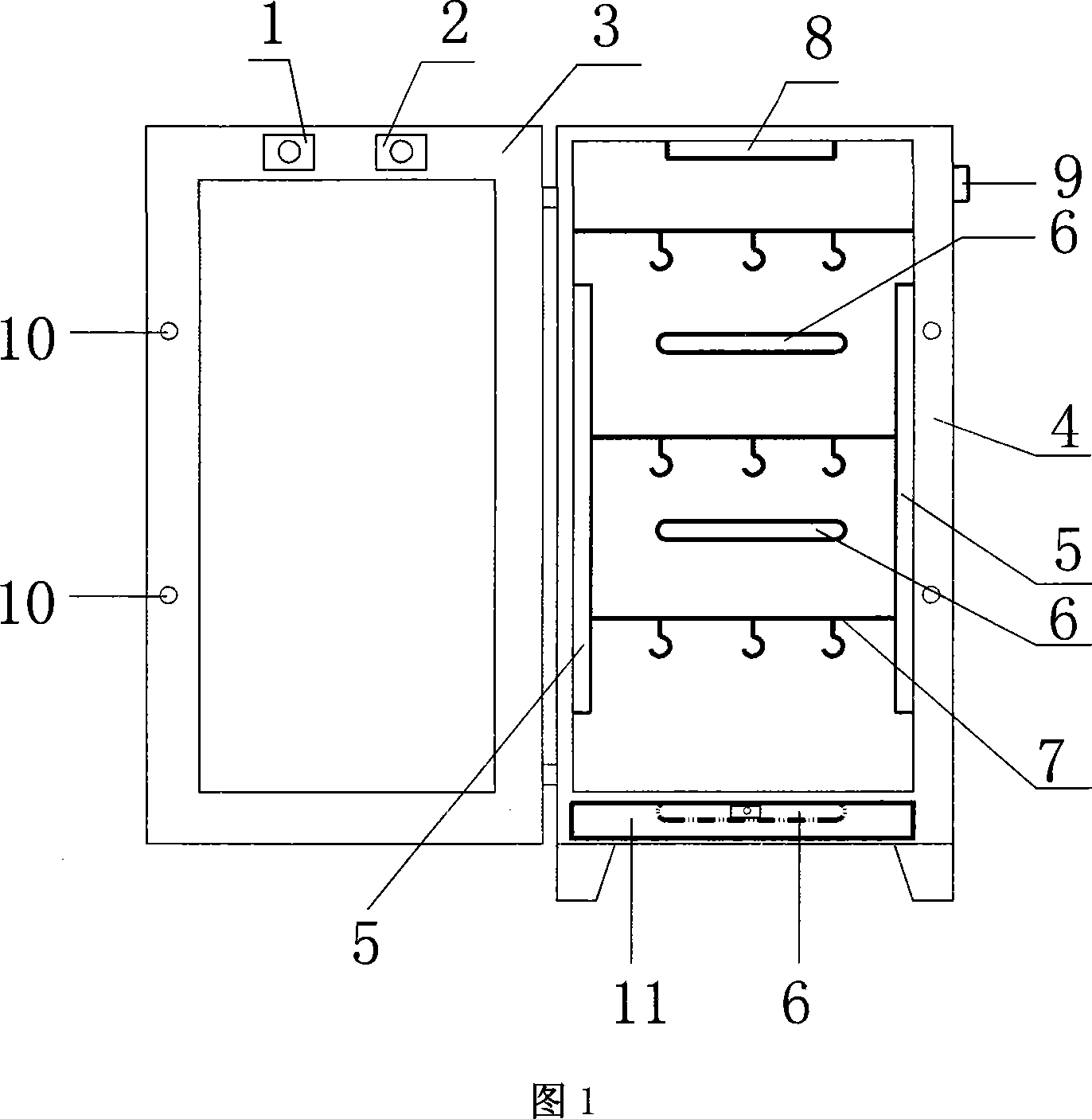

[0019] An ozone generator (8) is installed on the top of the waste blood treatment equipment cabinet to release an ozone concentration of 60mg / l, and a 20W ordinary hot cathode low-pressure mercury ultraviolet disinfection lamp (5) is installed on each of the left and right sides, and a single one radiates 253.7nm ultraviolet rays Intensity greater than 70μW / cm 2 , a quartz heating tube (6) is installed in the upper, middle and lower parts of the cabinet, and the main power switch (9), temperature control switch (1) and time control switch (2) are set outside the cabinet body, and the disinfection time is set to 100 minutes , the sterilization temperature is 75° C., and the plastic blood bag is suspended on the hanger (7). After disinfection, the pathogenic microorganisms inside and outside the plastic blood bag are all inactivated, and the blood coagulates into lumps.

Embodiment 2

[0021] An ozone generator (8) is installed on the top of the waste blood processing equipment cabinet to release an ozone concentration of 120mg / l. A 30W high-intensity ultraviolet disinfection lamp (5) is installed on each side of the left and right sides, and the intensity of a single 253.7nm ultraviolet light is greater than 200μW / cm 2 , a quartz heating tube (6) is installed in the upper, middle and lower parts of the cabinet, and the main power switch (9), temperature control switch (1) and time control switch (2) are set outside the cabinet body, and the disinfection time is set to 60 minutes , disinfection temperature 85 ℃, plastic blood bag is suspended on the hanger (7). After disinfection, the pathogenic microorganisms inside and outside the plastic blood bag are all inactivated, and the blood coagulates into lumps.

Embodiment 3

[0023] An ozone generator (8) is installed on the top of the waste blood processing equipment cabinet to release an ozone concentration of 100mg / l, and a 30W ordinary hot cathode low-pressure mercury ultraviolet disinfection lamp (5) is installed on the left and right sides, and a single one radiates 253.7nm ultraviolet rays Intensity greater than 100μW / cm 2 , the cabinet is provided with a quartz heating tube (6) at the upper, middle and lower parts respectively, and a main power switch (9), a temperature control switch (1) and a time control switch (2) are arranged outside the cabinet body, and the disinfection time is set at 85 Minutes, sterilizing temperature 90 ℃, plastic blood bag is suspended on the hanger (7). After disinfection, the pathogenic microorganisms inside and outside the plastic blood bag are all inactivated, and the blood coagulates into lumps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| UV radiation | aaaaa | aaaaa |

| UV radiation | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com