Steel blank heating device

A heating device and billet technology, which is used in the maintenance of heating chambers, lighting and heating equipment, furnace components, etc., can solve the problems of less flow heat and cannot be heated, and achieve the effect of good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

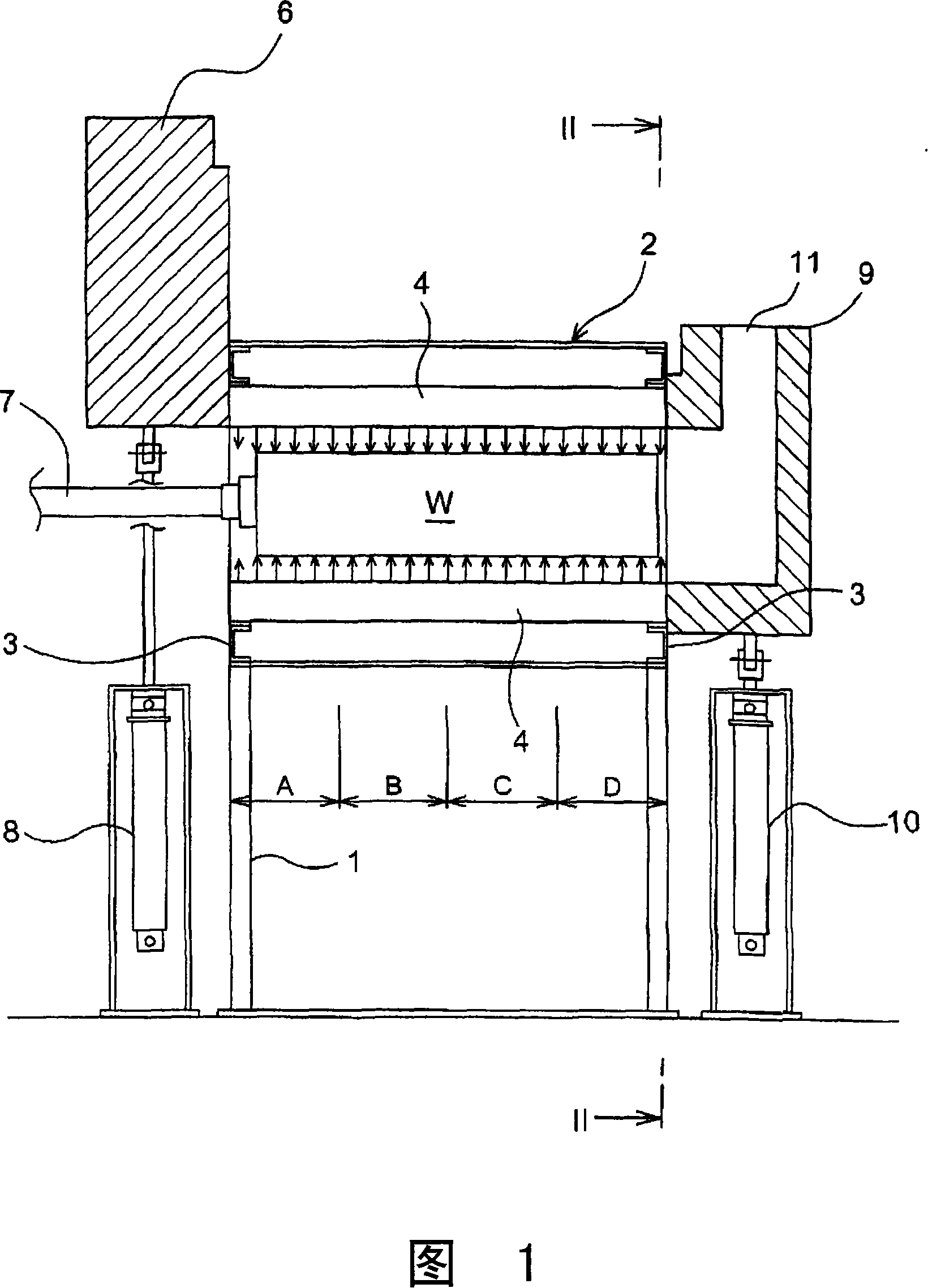

[0026] Fig. 1 and Fig. 2 show a heating apparatus for a slab W of the present invention.

[0027] The heating device has a body casing 2 provided on a stand 1 . The main body case 2 has an inverted U-shaped steel frame body 3 on the loading side and the pulling side of the billet W. Inside these frames 3, a plurality of (six in the embodiment) oxygen or oxygen-enriched burners 4 (hereinafter simply referred to as burner units) of a water-cooled structure supported at both ends are mounted. The burner units 4 are arranged at equal intervals in the circumferential direction, and extend in the longitudinal direction of the main body casing 2 , that is, from the insertion side to the extraction side. The main body casing 2 has no furnace wall, and is in a state in which the inside and the outside communicate with each other, and the burner unit 4 is installed in a state o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com