Kation S and anion N doped one-dimensional nano-structured Ti0* photocatalyst and method of producing the same

A nanostructure, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of inability to use visible light to degrade environmental pollutants, achieve excellent visible light catalytic activity, and is conducive to Reactivity, effect of reducing treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

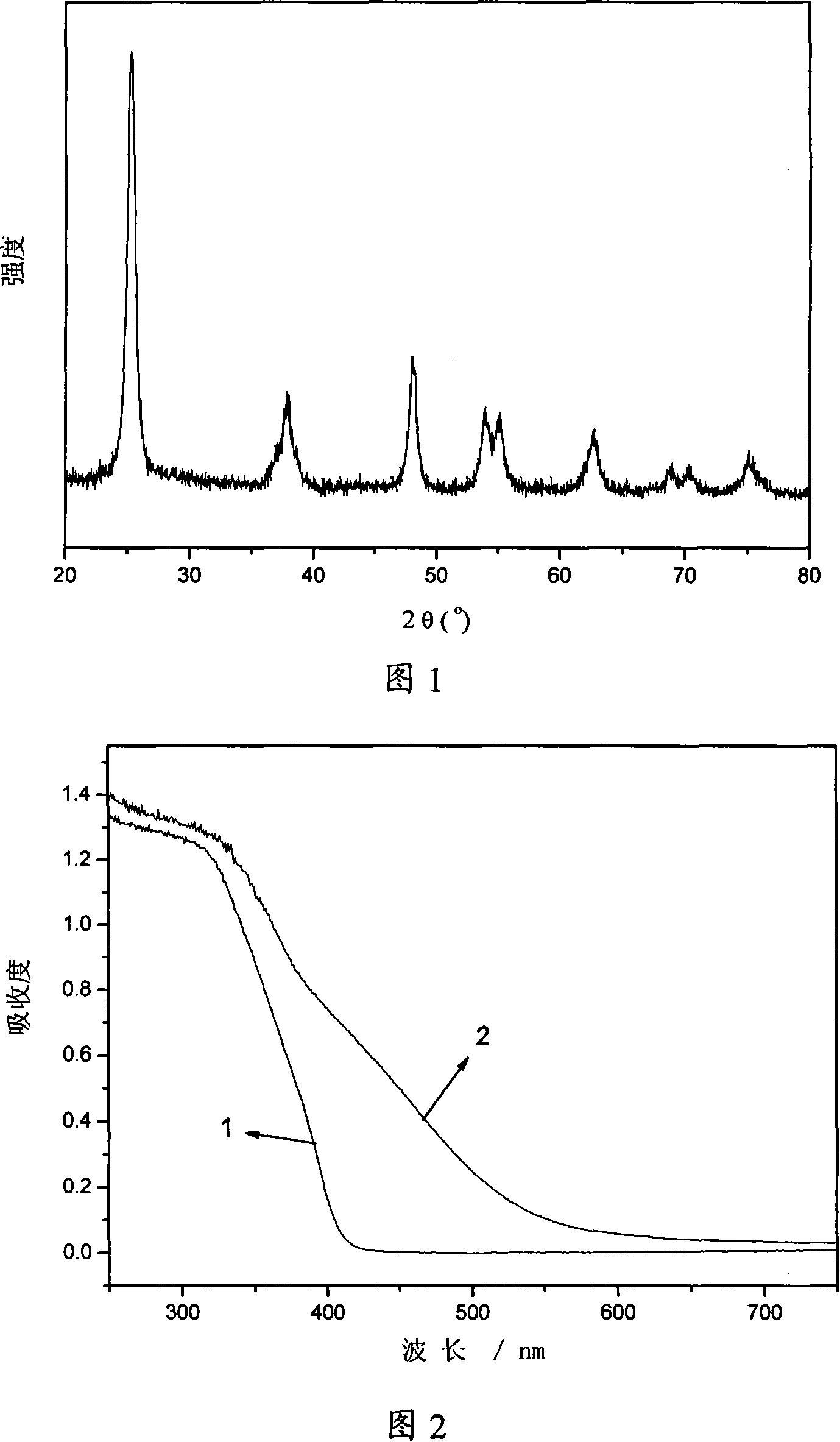

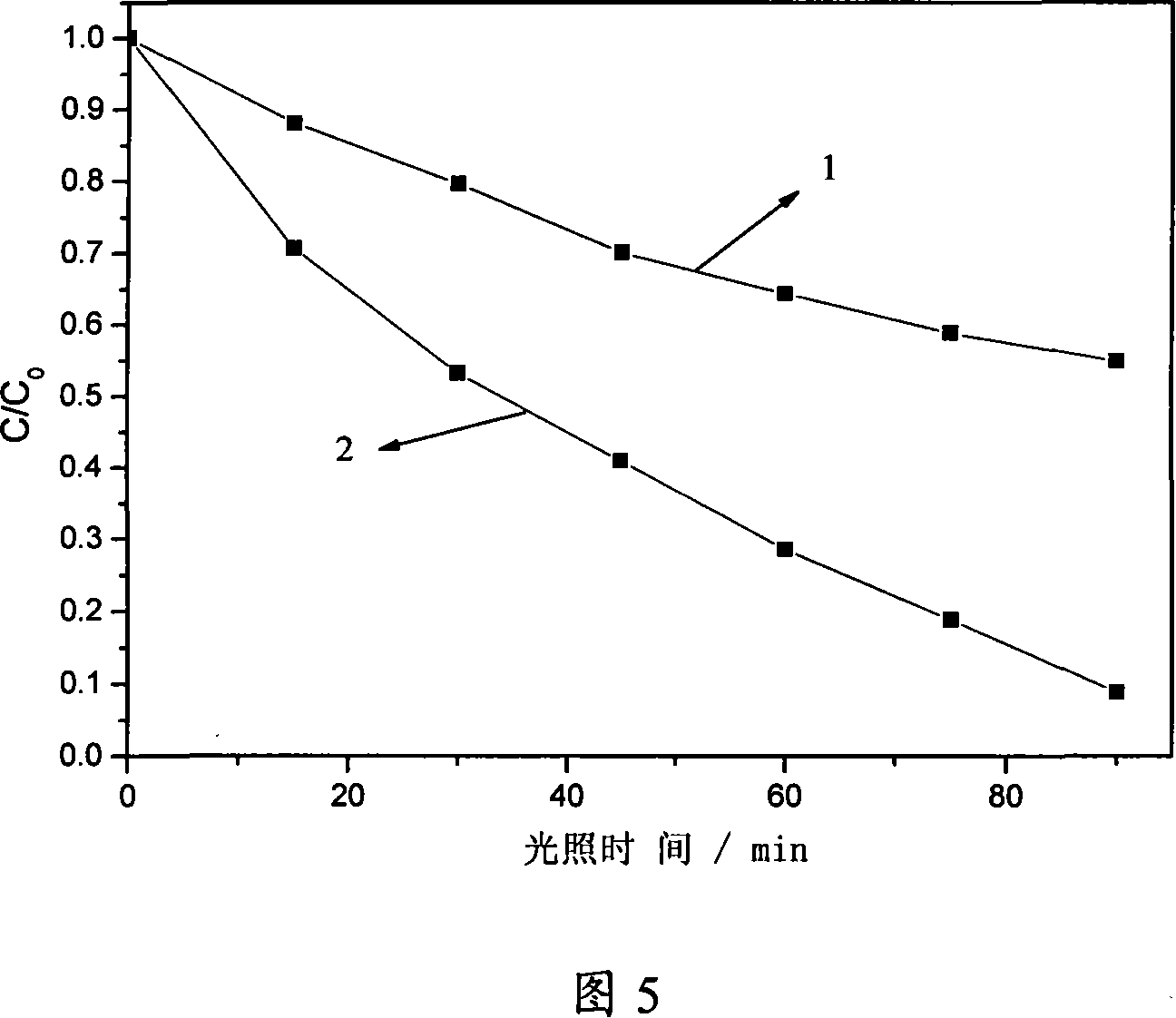

Embodiment 1

[0038] 2.0 g nano-TiO 2 The powder is placed in 70ml of 10mol / L NaOH solution, and continuously stirred to obtain 2 mixed solution. Transfer the above solution to a 100ml autoclave, keep the temperature at 150°C for 24 hours, cool, pour off the supernatant, and wash with 0.05mol / L hydrochloric acid solution and deionized water to obtain a white precipitate of hydrotitanic acid. Prepare the above hydrotitanic acid and doping source thiourea in a certain ratio (1:2) with absolute ethanol to form a mixed suspension, stir evenly, ultrasonically treat, and dry at 80°C for 10 hours to obtain a homogeneous mixture of hydrotitanic acid and thiourea . The above mixture was placed in a tube furnace and calcined at 400 °C for 2 h under anaerobic conditions to obtain cation S and anion N double-doped one-dimensional nanostructured TiO 2 , the doping amount of sulfur is 0.9%, the doping amount of nitrogen is 1.2%, the crystal form is anatase, and the shape is a nanotube with a length of...

Embodiment 2

[0042] 3.0 g nano-TiO 2 The powder is placed in 60ml of 12mol / L KOH solution and continuously stirred to obtain 2 mixed solution. Transfer the above solution to a 100ml autoclave, keep the temperature at 180°C for 36 hours, cool, pour off the supernatant, wash with 6.5mol / L sulfuric acid solution and deionized water, and obtain a white precipitate of hydrotitanic acid. Prepare the above hydrotitanic acid and doping source thiourea in a certain ratio (1:4) with absolute ethanol to form a mixed suspension, stir for a certain period of time, ultrasonically treat, and dry at 100°C for 8 hours to obtain a uniform mixture of hydrotitanic acid and thiourea mixture. The above mixture was placed in a tube furnace and calcined at 500 °C for 1.5 h under aerobic conditions to obtain cation S and anion N double-doped one-dimensional nanostructured TiO 2 , the doping amount of sulfur is 1.5%, the doping amount of nitrogen is 1.8%, the crystal form is anatase, and the shape is a nanowire ...

Embodiment 3

[0045] 5.0 g TiO 2 Colloid is placed in the 15mol / LNaOH solution of 140ml, keeps stirring, obtains containing TiO 2 Colloidal mixed solution. Transfer the above solution to a 200ml autoclave, keep the temperature at 120°C for 48 hours, cool, pour off the upper clear layer, wash with 3.0mol / L nitric acid solution and deionized water, and obtain a white precipitate of hydrotitanic acid. The above-mentioned hydrotitanic acid and doping source thiourea were formulated into a mixed suspension with absolute ethanol in a certain ratio (1:1), stirred for a certain period of time, ultrasonically treated, and dried at 60°C for 12 hours to obtain a homogeneous mixture of hydrotitanic acid and thiourea. mixture. The above mixture was placed in a tube furnace and calcined at 550 °C for 3 h under aerobic conditions to obtain cation S and anion N double-doped one-dimensional nanostructured TiO 2 , the doping amount of sulfur is 0.5%, the doping amount of nitrogen is 0.8%, the crystal form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com