Graphene/ stannic oxide nanometer compounding resistance type film gas sensor and manufacturing method thereof

A gas sensor, tin dioxide technology, applied in the direction of material resistance, etc., can solve the problems that the working temperature affects the stability of the sensor, it is difficult to prepare a portable instrument, and it is not suitable for use, and achieves good response reversibility, fast response reversibility, The effect of promoting gas adsorption and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

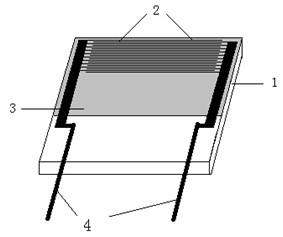

[0025] (1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

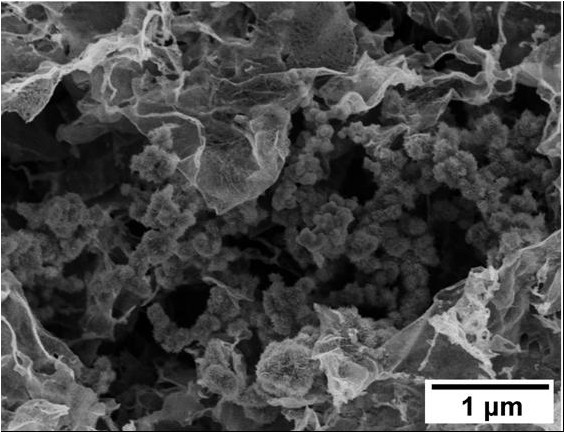

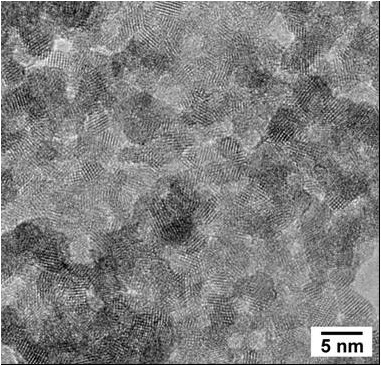

[0026] (2) Prepare a graphene oxide aqueous solution with a concentration of 0.01 mg / mL, then add tin dichloride dihydrate and urea, the weight ratio of graphene oxide aqueous solution, tin dichloride dihydrate and urea is 1:0.00225:0.01, stir and ultrasonic vibration to make sufficient mixing to prepare a precursor solution, add the precursor solution to a hydrothermal kettle and react at 80°C for 2 hours to prepare a graphene / tin dioxide nanocomposite solution;

[0027] (3) The graphene / tin dioxide nanocomposite solution prepared in step (2) was drip-coated on the surface of the interdigitated gold electrode with a ceramic substrate in step (1), and heat-treated at 140°C for 0.5 hours to prepare graphene / SnO nanocomposite resistive thin film gas sensor.

Embodiment 2

[0029] (1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0030] (2) Prepare a graphene oxide aqueous solution with a concentration of 5 mg / mL, then add tin dichloride dihydrate and urea, the weight ratio of graphene oxide aqueous solution, tin dichloride dihydrate and urea is 1:0.00225:0.005, stir and ultrasonic vibration to fully mix to obtain a precursor solution, add the precursor solution to a hydrothermal kettle and react at 100°C for 12 hours to obtain a graphene / tin dioxide nanocomposite solution;

[0031] (3) The graphene / tin dioxide nanocomposite solution prepared in step (2) was drip-coated on the surface of the interdigitated gold electrode with a ceramic substrate in step (1), and heat-treated at 80°C for 3 hours to obtain graphene / SnO nanocomposite resistive thin film gas sensor.

Embodiment 3

[0033] (1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0034] (2) Prepare a graphene oxide aqueous solution with a concentration of 5 mg / mL, then add tin dichloride dihydrate and urea, the weight ratio of graphene oxide aqueous solution, tin dichloride dihydrate and urea is 1:0.0225:0.025, stir and ultrasonic vibration to mix thoroughly to obtain a precursor solution, add the precursor solution to a hydrothermal kettle and react at 120°C for 12 hours to obtain a graphene / tin dioxide nanocomposite solution;

[0035] (3) The graphene / tin dioxide nanocomposite solution prepared in step (2) was drip-coated on the surface of the interdigitated gold electrode with ceramic substrate in step (1), and heat-treated at 100°C for 2 hours to obtain graphene / SnO nanocomposite resistive thin film gas sensor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com