Preparation method for graphene heating film

A graphene heating film and graphene technology, applied in the field of preparation of graphene heating film, can solve the problems of complex preparation process and low heating efficiency, and achieve the effects of simple production and preparation process, high heating efficiency and uniform product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

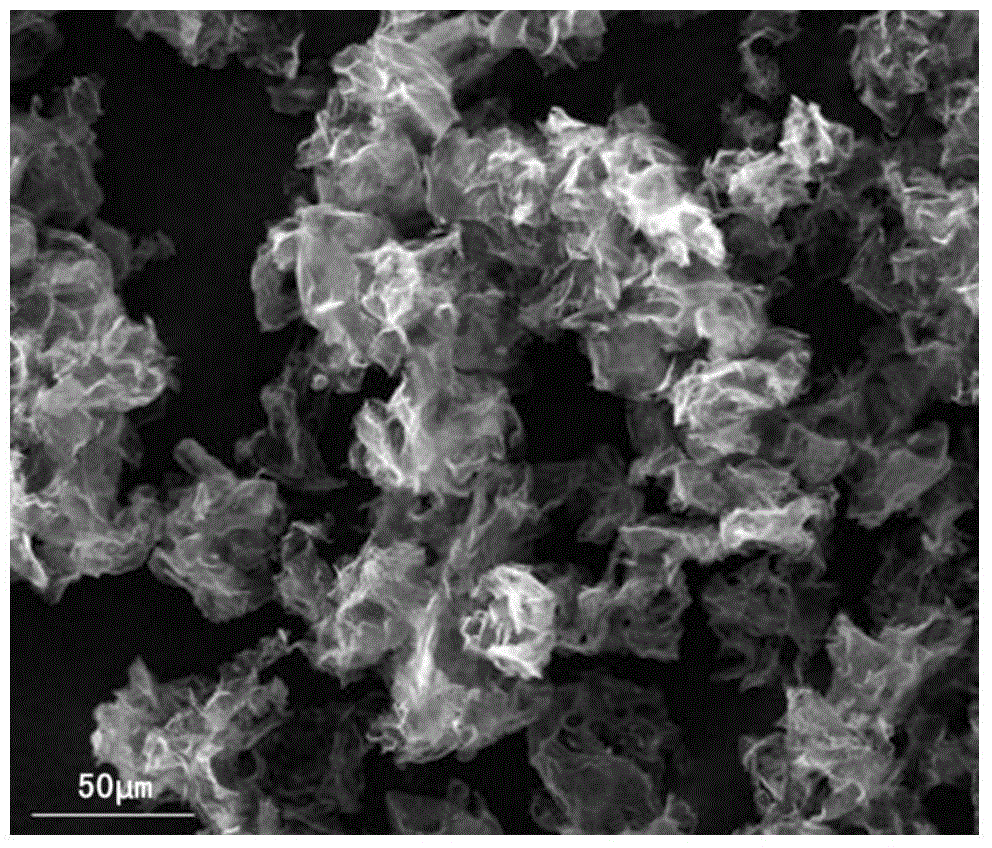

[0024] The preparation process of the graphene heating film of the present invention is as follows: the graphene powder is uniformly dispersed in an organic solvent to obtain graphene with a concentration of 0.05mg / ml-0.5mg / ml (preferably 0.1mg / ml-0.3mg / ml) Colloidal suspension; the graphene is evenly covered on the organic filter membrane or water filter membrane by vacuum filtration, and then after natural drying or heating drying, the graphene film is separated by mechanical peeling, soaking or organic solvent dissolution and filter membrane to obtain a uniform and stable graphene film. Electrodes are added to the graphene film, and heat can be generated by applying voltage.

[0025] The present invention adopts a conventional vacuum suction filtration device, which includes: a 300ml Buchner funnel, a glass sand core filter, a 1000ml-2000ml suction filter bottle and connecting flexible pipes and clamps, and the vacuum pump used can be a circulating water vacuum pump Or an ...

Embodiment 1

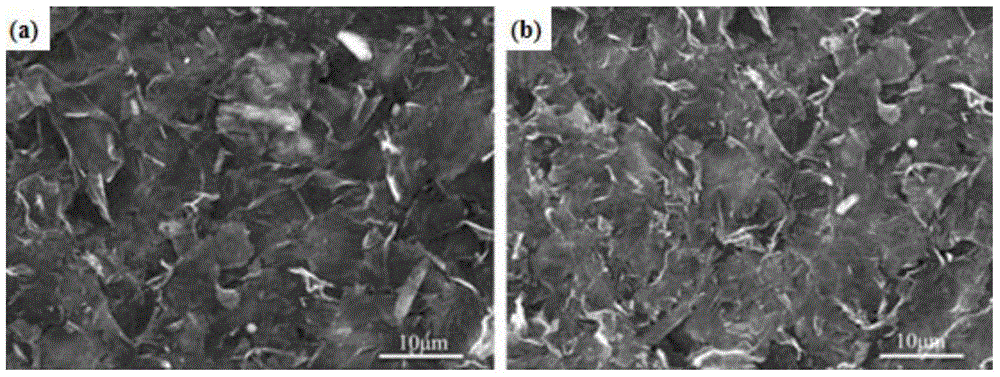

[0030] Weigh 9.375 mg of graphene powder and put it in a beaker, add 50 mL of absolute ethanol reagent, and ultrasonically disperse for 1 h to obtain a homogeneous and stable graphene colloidal suspension with a concentration of 0.1875 mg / mL. The graphene colloidal suspension is placed on the microporous filter membrane in the vacuum filtration device, using a polyvinylidene fluoride filter membrane with a pore size of 0.45 μm, the pressure of the vacuum filtration is 0.08 MPa, and the time is 15 minutes. After the suction filtration is completed, the graphene film and the filter membrane are placed in a 45° C. drying oven for 24 hours to dry, and then the graphene film is obtained by mechanical peeling. From figure 2 (a) and image 3 It can be seen that the surface of the graphene film obtained by vacuum filtration is even and smooth, and the sheets overlap tightly.

[0031] The surface density of the graphene film that utilizes this method to make is 15g / m 2 , the thickn...

Embodiment 2

[0033] The difference from Example 1 is that 18.750 mg of graphene powder was weighed and placed in a beaker, 100 mL of N,N-dimethylformamide reagent was added, and ultrasonically dispersed for 1 hour to obtain a homogeneous and stable powder with a concentration of 0.1875 mg / mL. graphene colloidal suspension. The graphene colloidal suspension is placed on the microporous filter membrane in the vacuum filtration device, using a polytetrafluoroethylene filter membrane with a pore size of 0.45 μm, the pressure of the vacuum filtration is 0.15 MPa, and the time is 35 minutes. After the suction filtration is completed, place the graphene film together with the filter membrane in a drying oven at 100° C. for 38 hours, and then adopt a mechanical stripping method to obtain a graphene film. figure 2 (b) It can be seen that the surface of the obtained graphene film is uniform and flat, and the sheets overlap closely.

[0034] The surface density of the graphene film that utilizes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com