Gold base alloy chemical composition analytical method

A technology of chemical composition and gold-based alloy, which is applied in the field of chemical analysis, can solve problems such as impossibility and difficulty in completely dissolving gold-based alloys, and achieve the effect of improving product quality and eliminating unqualified materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

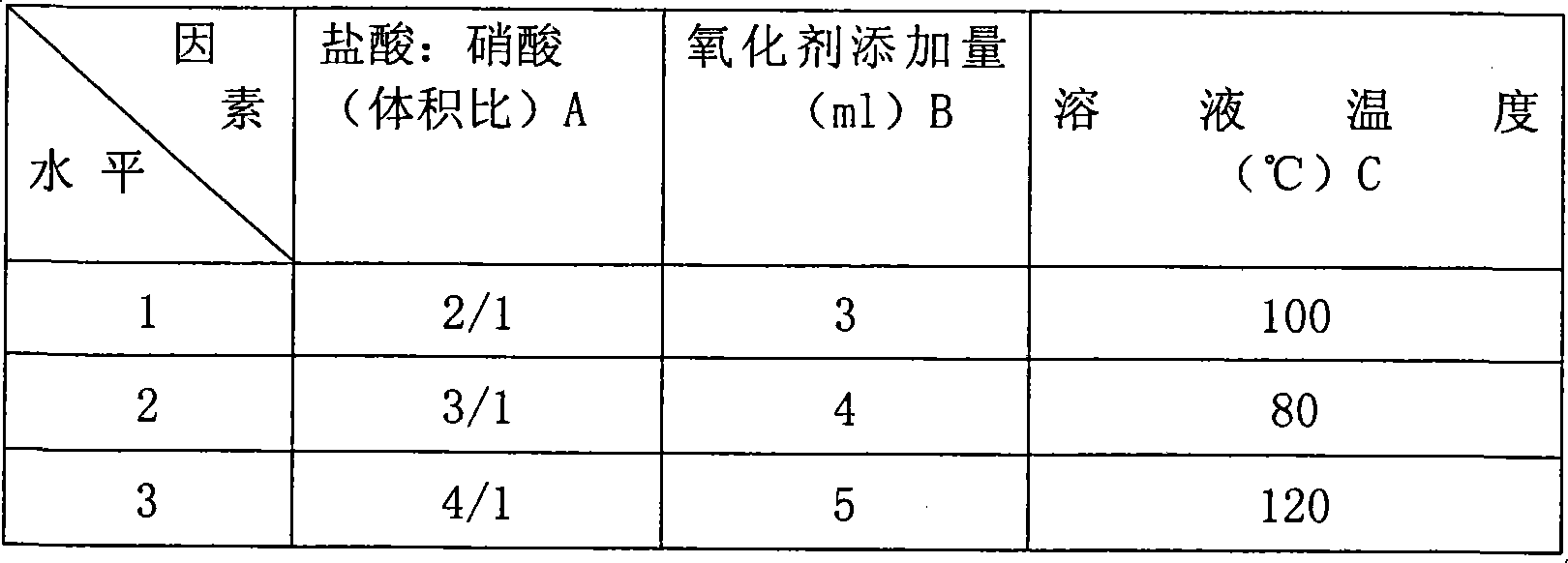

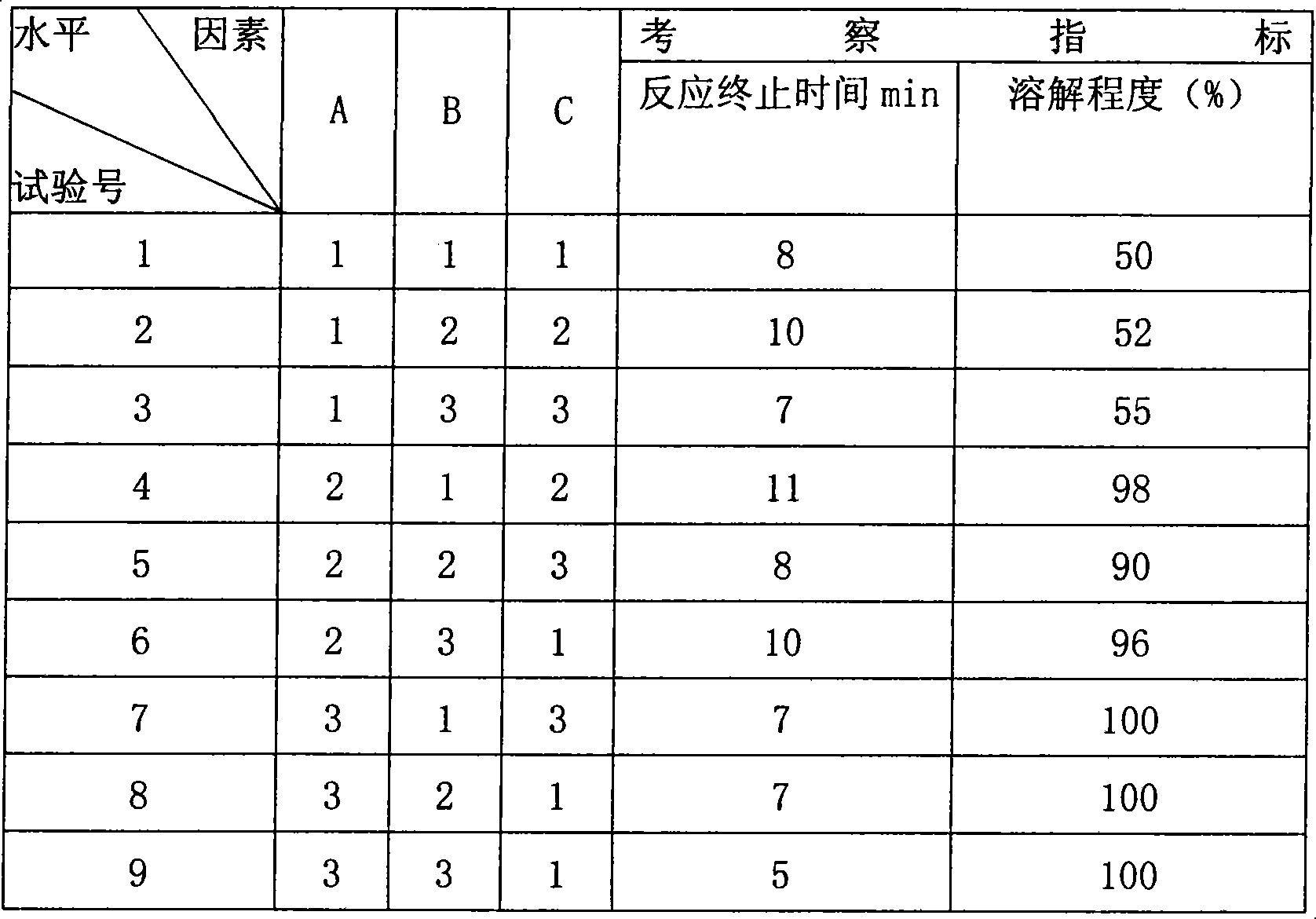

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with embodiment.

[0015] Enlarging the ratio of hydrochloric acid: nitric acid to make it greater than the traditional 3:1 ratio is the key measure to realize the complete dissolution of silver chloride and prevent precipitation, which is conducive to the complete dissolution and overcomes the problem of silver chloride covering the test area in the traditional proportioning. The sample surface prevents the depth of dissolution from proceeding.

[0016] Secondly, the speed of dissolution is promoted by slow heating.

[0017] The present invention will be further described below by taking a specific gold-based alloy as an example.

[0018] A kind of AuAgNiCu22-3-1 gold base alloy chemical composition analysis method, it comprises following work process:

[0019] 1. Decomposition of the sample

[0020] Weigh 0.1000g sample, accurate to 0.0001g. Place the sample in a 250ml beaker, add 40ml of 4-5:1 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com