Cylindrical lithium-sulfur battery and preparation method thereof

A lithium-sulfur battery, cylindrical technology, applied in the field of cylindrical lithium-sulfur battery and its preparation, can solve problems such as polysulfide compound dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a cylindrical lithium-sulfur battery, specifically:

[0040] S1. Preparation of positive electrode slurry: Mix deionized water and water-based glue according to the weight ratio of 100: (15-20) and stir for 25-35 minutes; add the weighed conductive agent to the stirred glue, and continue stirring for 25-20 minutes. 35min; add the sulfur-polyacrylonitrile positive electrode active material into the stirred mixture, and continue to stir for 150-240min; then add the solvent, its components are single-component or multi-component alcohol solvent and water-based slurry, the weight ratio is 100: (10-40) continue to stir for 25-35 minutes to prepare positive electrode slurry;

[0041] S2. Preparation of the positive electrode sheet: filter the positive electrode slurry prepared in step S1, evenly coat it on an aluminum foil with a thickness of 12-18um, carry out coating on both sides and dry it at 50-90°C; put the above-mentioned electrode sheet into In...

Embodiment 1

[0057] Step 1. Preparation of positive electrode slurry: Mix deionized water and water-based glue according to the weight ratio of 100:20 and stir for 30 minutes; add the weighed conductive agent to the stirred glue, and continue stirring for 30 minutes; Add the nitrile positive electrode active material into the stirred mixed solution and continue to stir for 180 minutes; then add a solvent whose components are single-component or multi-component alcohol solvent and water-based slurry, the weight ratio is 100:40 and continue to stir for 30 minutes to prepare the positive electrode slurry;

[0058] Step 2. Preparation of positive electrode sheet: filter the positive electrode slurry prepared in step S1, evenly spread it on an aluminum foil with a thickness of 18um, and carry out coating on both sides and dry it at 60°C; put the above-mentioned electrode sheet into a vacuum oven : The temperature is 90°C, the vacuum degree exceeds -0.096Mpa, and baked for 16 hours; the dried po...

Embodiment 2

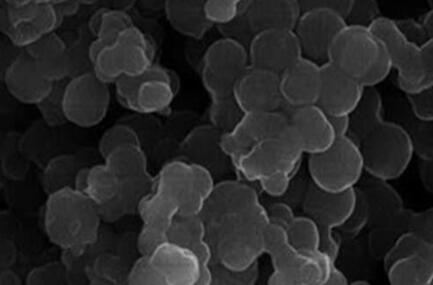

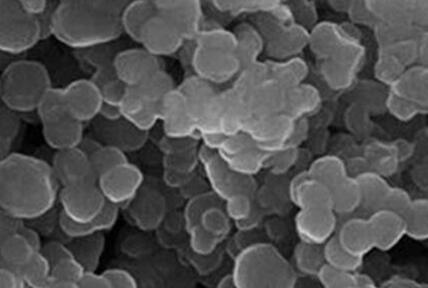

[0066] Preparation of positive electrode sheet: Hollow mesoporous carbon spheres were prepared by the hard template method, and then compounded with sulfur at high temperature to obtain a "carbon-in-sulfur" type sulfur-hollow carbon sphere composite material, that is, a conventional polysulfide compound .

[0067] Other steps are the same as in Example 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com