Termpered layer composite solid wooden board and its processing method

A processing method and solid wood board technology, which is applied in the field of wood board processing, can solve problems such as poor wear resistance and impact resistance, loss of decorative functions, poor dimensional stability, etc., to achieve good shape retention, maintain foot comfort, and stable size good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1), make the panel

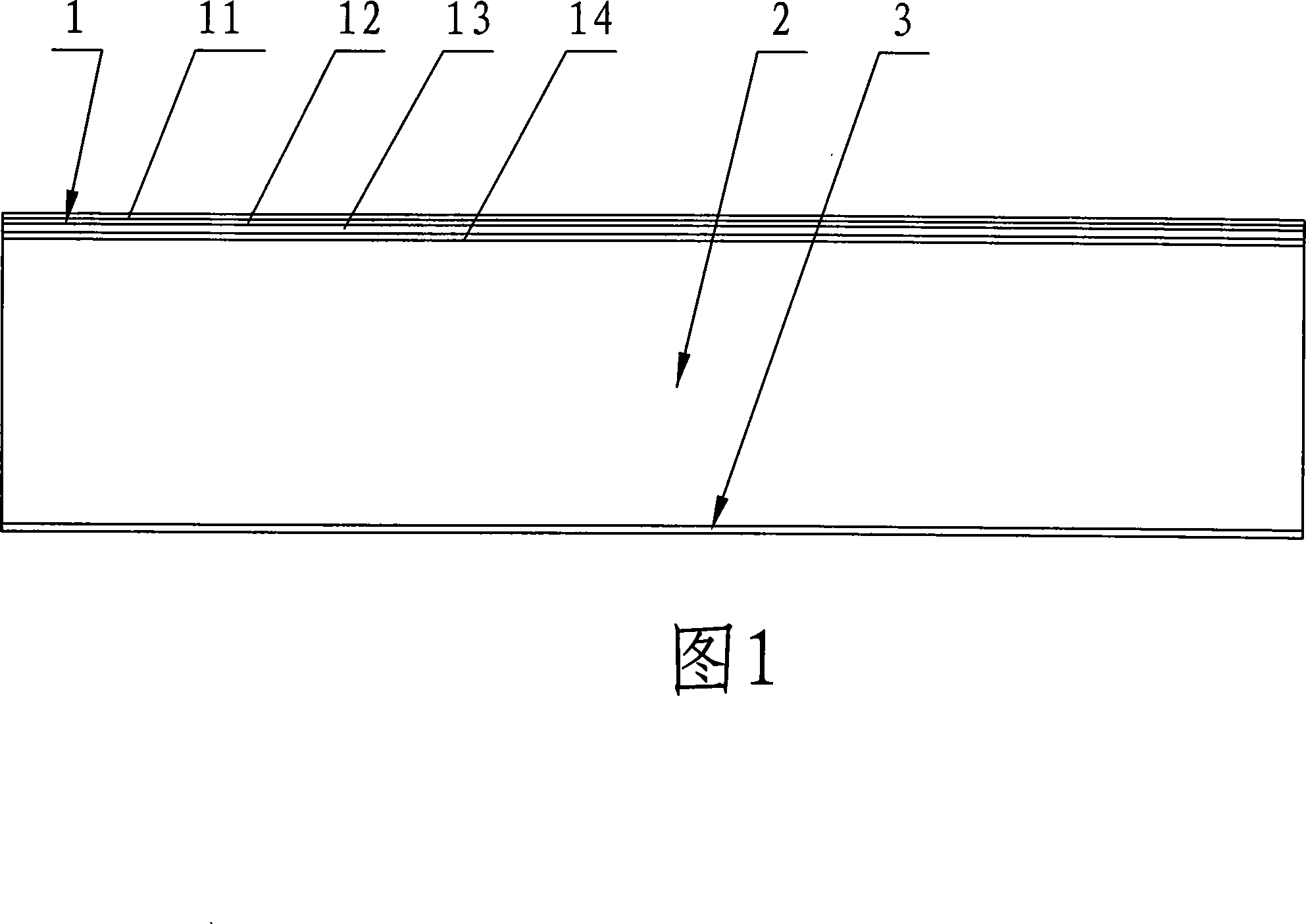

[0021] First, the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are dipped in melamine glue and dried, and then the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are stacked on the lower platen of the press in sequence , the upper and lower templates are held at a pressure of 10MPa~14MPa and a temperature of 150℃~160℃ for 30s~50s, and the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are hot-pressed and connected to form a surface layer, and naturally cooled .

[0022] (2), pressing compound

[0023] Double-sided glue coating on the base layer, the base layer is made of finger-jointed board, the bottom layer is made of balance paper, and the balance paper is also impregnated with melamine glue. With a pressure of 5MPa-16MPa and a temperature of 20°C-100°C for 10min-30min, the bottom layer, base layer and surface layer are crimped a...

Embodiment 2

[0027] (1), make the panel

[0028] First, the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are dipped in melamine glue and dried, and then the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are stacked on the lower platen of the press in sequence , the upper and lower templates are held at a pressure of 13MPa-16MPa and a temperature of 160°C-180°C for 30s-50s, and the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are hot-pressed and connected to form a surface layer, and naturally cooled .

[0029] (2), pressing compound

[0030] Double-sided adhesive coating on the base layer, the base layer is made of finger joint board, and the bottom layer is made of fiberboard. In order to place the surface layer, base layer and bottom layer on the lower template of the press in sequence, the pressure and temperature of the upper and lower templates are between 5MPa and 1...

Embodiment 3

[0034] (1), make the panel

[0035] First, the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are dipped in melamine glue and dried, and then the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are stacked on the lower platen of the press in sequence , the upper and lower templates are pressed at a pressure of 15MPa~18MPa and a temperature of 150℃~160℃ for 30s~50s, and the wear-resistant layer, decorative layer, quartz fiber layer and polyester fiber layer are hot-pressed and connected to form a surface layer, and naturally cooled .

[0036] (2), pressing compound

[0037] Double-sided glue coating on the base layer, the base layer is made of solid wood spliced board or solid wood finger joint board, solid wood composite multi-layer board or solid wood glulam, and the bottom layer is made of veneer, in order to place the surface layer, the base layer and the bottom layer on the bottom of the press in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com